Is there an AM culture?

While "business" and "culture" are well-known concepts individually, their combination into "business culture" creates a complex and multifaceted field. In this industry, understanding it...

Joy Gockel on workforce development needs and opportunities in AM

Have you ever realized that most AM experts who have started their career in academia usually move to the industry side after some time?...

Going through Arkema’s ESG and sustainability journey in Additive Manufacturing

It’s been a few years already that we continuously monitor sustainability activities in the AM industry. Last year, in the sustainability edition of 3D...

Frank Rethmann on the AM journey of Airbus Helicopters: “Since 2017, we have produced more than 13500 shafts [using titanium 3D printing].”

I may have been blinded by the number of war films and thrillers that I have already watched, but I consider helicopters as one...

Pratt & Whitney on the evolutionary journey that leads to the development of military engines with Additive Manufacturing

Many military aircraft, especially fighters, require engines with significant differences from commercial aircraft. They fly different flight profiles and perform various jobs. These differences...

Automotive AM at Toyota: Challenges in (complex) applications with Additive Manufacturing

Have automotive parts been a difficult space for AM to grow? : The Toyota case

When I started covering the AM industry, one of the...

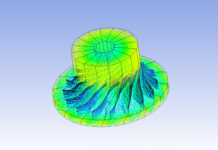

How multiphysics simulation optimizes additive manufacturing processes for the electronics industry

According to Additive Manufacturing Research (AMR), the electronic additive manufacturing market could reach $7.9 billion by 2033. However, the industrialization of additive manufacturing (AM)...

AM Shapers | Behind the scenes of Ford’s AM journey in Europe

“The number of 3D printers you have does not tell the full story”

If I had to pass an exam where I am asked to...

Q&A | BMF on the current state of the micro 3D printing market and where it is headed for

Two years ago, when we discussed the fundamentals at the heart of micro 3D printing technologies, we didn’t realize how strong the impact of...

Differences in the pace of AM adoption across regions: The Lithoz case

Last year, when machine manufacturer Thermwood launched its Cut Layer Additive solution, an Additive Manufacturing process that does not 3D print, the machine received...

![Frank Rethmann on the AM journey of Airbus Helicopters: “Since 2017, we have produced more than 13500 shafts [using titanium 3D printing].”](https://3dadept.com/wp-content/uploads/2025/05/Credit-Airbus-Helicopters-–-CityAirbus-NextGen-2-218x150.jpg)