Vivobarefoot introduces 3D printed barefoot sandals

Vivobarefoot, a running shoe company, expands its portfolio with the launch of 3D-printed barefoot sandals named VivoBiome Tabi Gen 01.

The scan-to-print process helps to...

Walmart to open a second 3D printed store

Walmart made a real splash last year when it announced the construction of one of the largest freestanding, 3D-printed commercial concrete structures in Tennessee,...

TEMISTh additively manufactures heat exchangers for aerospace, defense, and energy industries

While Conflux Technology has brought significant attention to the use of metal 3D printing for thermal applications, a closer look at the industry's history...

Divergent and CoAspire deliver 3D printed RAACM cruise missile in record time

Divergent Technologies, Inc. – the company behind the Divergent Adaptive Production System (DAPS), joined forces with CoAspire to design and additively manufacture CoAspire's Rapidly Adaptable...

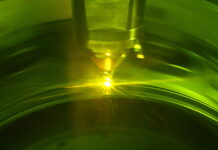

LFAM: LEAP 71 to develop meganewton-class propulsion systems

As part of its rocket engine program and on the heels of the validation of smaller-scale engines, global software developer LEAP 71 plans to...

Download the 2025 March/April edition of 3D ADEPT Mag

What if more accessibility leads to mass customization?

Each year, one edition of 3D ADEPT Mag goes beyond the usual news on product launches and...

Pratt & Whitney bets on additive manufacturing to repair GTF engines

Pratt & Whitney, an RTX business, uses additive manufacturing (AM) to repair critical GTF engine components that will reduce process time by more than...

Renishaw and Metalpine to develop 3D printed parts for harsh marine environments

OEM 3D printing provider Renishaw is working with material producer Metalpine, on the development of marine applications. Both teams aim to create copper-nickel alloy (CuNi) powders...

Dolce Vita to rely on HILOS’ platform to produce on-demand, 3D printed footwear

Footwear and accessories brand Dolce Vita® relies on HILOS’ software platform to produce on-demand, 3D printed footwear. As a reminder, last year, HILOS introduced a new...

PROTEOR introduces a 3D printed non-vase mode definitive socket

PROTEOR, an expert in prosthetics and orthotics (O&P), introduces non-vase mode definitive sockets.

For those who are not familiar with the expression, in 3D printing,...