CFIP: A post-processing solution designed to reinforce plastic, metal or ceramic 3D printed parts

Most experts would tell you that Additive Manufacturing's ability to deliver lightweight structures can be mainly achieved through lightweight design. Considered one of the...

Ten years later, construction 3D printing company WASP shares more details about “Shamballa”

In 2016, construction 3D printing company WASP introduced the Shamballa project, inspired by the ideal of peace and harmony embodied in the legendary place...

Advancing patient care through 3D printing and sintering technologies

The medical industry is witnessing a transformative era with the rapid adoption of powder metallurgy (PM) and additive manufacturing (AM) technologies. From patient-specific implants...

3D Systems’ new FDA-cleared denture solution is now available in the USA

3D Systems’ NextDent Jetted Denture solution aims to address all major facets of dentistry to straighten, protect, repair and replace teeth.

Approved last year by...

Authentise and Kform introduce CHOPS model to accelerate defence manufacturing workflows

CHOPS aims to replace siloed engineering with live, traceable delivery from idea to part.

Authentise, an expert in digital manufacturing workflow software, joins forces with Kform,...

What type of parts drives the composites AM market?

With a market that is expected to surpass $9 Billion in 2028, composites continue to strengthen their reputation as the strongest and most durable...

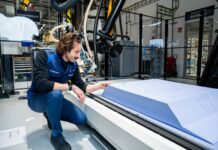

BMW Group uses recycled material to produce new 3D printed parts

In 2018, BMW Group started the “bottleUP” project, which focused on obtaining 3D printing material for various applications by recycling PET bottles. A year after...

AMAZEMET introduces on-demand atomization service

AMAZEMET, a company advancing research and development in materials science and additive manufacturing, recently introduced its Atomization Service. This on-demand service is designed to...

Bentley’s EXP 15 design concept features 3D printed titanium finishes

It’s just a design concept, but we already look forward to seeing the final version. Car manufacturer Bentley just unveiled its latest luxury vision...

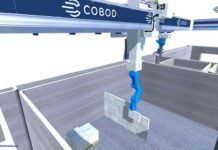

COBOD introduces a multifunctional construction robot for construction 3D printing

Construction 3D printer manufacturer COBOD International introduces a multifunctional construction robot, made in collaboration with Technische Universität Braunschweig.

The telescope unit of the system has...