AMGTA issues research on sustainability of powder and wire additive feedstock

The Additive Manufacturer Green Trade Association (“AMGTA”), a global advocacy group focused on promoting sustainable additive manufacturing (“AM”) industry practices, announced today the preliminary...

New elastomer-based ink can help 3D print flexible devices without mechanical joints

For engineers working on soft robotics or wearable devices, keeping things light is a constant challenge: heavier materials require more energy to move around,...

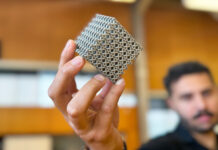

New plastic coating solution enhances functionality of 3D printed parts

A research team from the University of Nottingham, has developed a new coating for plastic particles that would increase the functionality of 3D printed...

NVIDIA’s LATTE3D model transforms text into 3D generative AI model

The next step will be the transformation of text into 3D-printable file

Researchers from software provider NVIDIA have enhanced their latest text-to-3D generative AI model, dubbed LATTE3D.

Like...

New research to explore the development of an SLS 3D printing material from recycled polypropylene

Andaltec Technological Centre has begun research on the RECYPPOWDER project, aimed at developing a new family of innovative economical and sustainable materials from recycled...

Fraunhofer IGD technology can deliver computer-generated 3D-printed eye prostheses

Fraunhofer IGD, the research institute behind the Cuttlefish® 3D printer driver – first unveiled in 2021, has given hope to patients who need ocular...

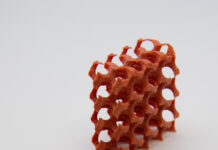

RMIT develops a 3D printed ‘metamaterial’ with properties not normally seen in nature

This title looks like the beginning of a Sci-Fi book but it is not. Researchers from Australia-based RMIT have developed a new metamaterial –...

When 3D printing helps to enhance breast reconstruction surgery

Across the world, several organizations have been exploring the use of 3D printing for breast implants. While several developments are still in progress, the...

The iLAuNCH project team relies on AM of large-scale composite structures to build a rocket

To withstand the extreme loads, vibrations and shocks of launch without failure, it is of paramount importance that launch vehicles benefit from scalable production...

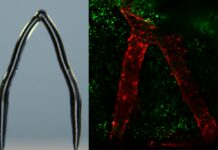

Have you heard about 3D ice printing? It can help create structures that resemble blood vessels in the body

When they say, 3D printing can help create “anything”, this might actually be true. We have witnessed the possibility of 3D printing to process...