Canada-based machine manufacturer AON3D announces a major upgrade for its M2+ high temperature industrial 3D printer. As a reminder, the 3D printer was released last year, with the goal of delivering high-end features and advanced material capabilities to the mid-market customer.

True to its commitment to deliver high end features and in order to duplicate the output of new and existing M2+ machines, the machine manufacturer has integrated a firmware upgrade that enables Duplication Mode and Mirror Mode 3D printing.

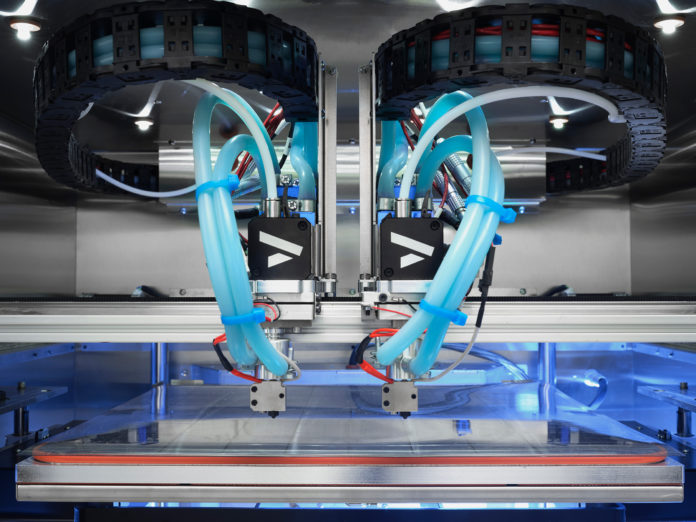

With this upgrade, the AON M2+ will be able to print two of the same part, or two mirrored parts concurrently via an Independent Dual Extrusion (IDEX) system, doubling the machine’s output. A similar system has already be seen in BCN3D and Essentium 3D printers.

Not only does it enhance production capabilities, but it allows for greater design freedom. In this specific case, AON3D explains users of the M2+ could easily print large internal geometries and non-liner holes with water-soluble support options. Most importantly, the IDEX system facilitates the processing of high-performance materials, like PEEK, PEKK, and ULTEM™, which deliver some of the most-sought material properties in 3D printing applications. These properties include for instance a higher strength to weight ratio than many metals, a high heat resistance – continuous use temperatures up to 260°C, a high chemical & hydrocarbon resistance or even a low friction / high wear resistance.

“With the Duplication Mode upgrade, the AON M2+ offers twice the size, twice the output, and more material options than any sub-$60k high temperature 3D printer on the market. Duplication and Mirror Mode are expected to be available via firmware upgrade by fall of this year. Existing AON M2+ customers on a success plan will receive the update free of charge. Combined with ungated access to advanced thermoplastics, largest-in-class build volume, and features that minimize part post-processing, the AON M2+ continues to be the agile manufacturing solution of choice by companies globally — capable of producing functional end-use parts at scale in half the time compared to any other high temperature 3D printer”, the company said in a press communication.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com