Anisoprint and Polymaker have announced a collaboration that aims to explore a wide range of properties for composite 3D Printed parts.

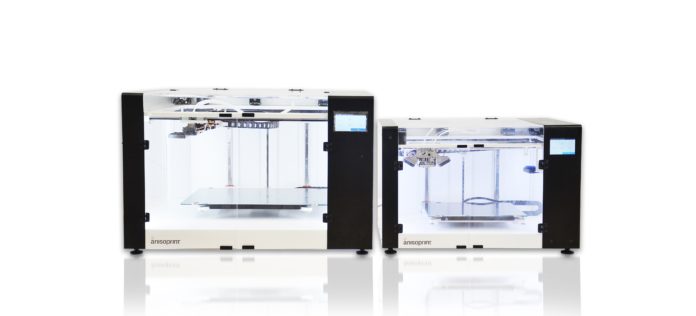

As a reminder, Anisoprint develops and commercializes desktop 3D printers intended for the manufacture of industrial-grade parts whereas Polymaker is acknowledged for the production of engineering grade 3D Printing materials including PETG, ABS, PC, PLA, PAs, etc.

Polymaker’s materials combine a wide range of properties: heat, chemical, weather and impact resistance.

Anisoprint continuous fiber 3D printing on the other hand allows the user to choose any plastic with a processing temperature up to 270°С as a matrix material. In this vein, both companies aim to enable the additive manufacturing of composite pars with a wide range of mechanical properties.

A quick look at the production of a clevis

A clevis has been 3D printed on Anisoprint Composer 3D Printing using PETG reinforced with Composite Carbon Fiber. This addition enables to obtain a tough and rigid part, resistant to peroxide.

Based on the graphic, the original part from milled polyamide required 3 months for its production whereas the use of AM with composite Carbon Fiber only took 6 hours.

According to the Luxembourg-based manufacturer, once the CFC (Composite Fiber Co-extrusion) technology is reinforced with continuous composite fibers, it results in a strong, light and relatively cheap part with the required properties.

Given the wide range of physical properties polymers integrate, combining Anisoprint and Polymaker’s expertise provides manufacturing solutions for companies in several fields.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !