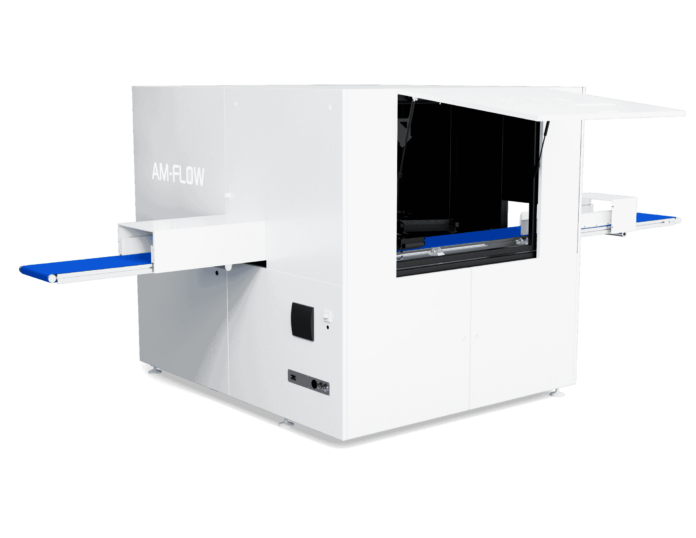

Two years ago, to facilitate the transition from prototyping to series production, workflow automation company AM-Flow developed an AM In-Line Quality Control solution for the steps that follow the manufacturing process.

Simply put, this solution aimed at identifying a defect more accurately and quickly. It also gave an automatic reprint signal while collecting data about detected errors in geometries. Today, the company unveiled an improved version of this solution.

Designed for both traditional and Additive Manufacturing, it can conduct comprehensive scans with a 50 μm accuracy, capturing even the smallest details of each part. It can also identify issues such as breakages, warping, and surface defects, and ensures the correction of sub-quality prints directly during production.

AM-Flow explains its patented technology adapts to infinite geometries, seamlessly integrating into any production line. The system performs rapid OK/Not OK evaluations within a 5-second takt-time, with the option to generate full metrology reports. It can also inspect up to 720 products per hour.

Utilizing eight high-speed CMMs, AM-QUALITY generates accurate 3D scans compared to nominal digital-source files (such as STL, STEP, and CAD), ensuring thorough assessments of every part.

Visitors at Formnext 2024 could discover more about this solution in Booth H12.1, C19.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.