OEM AddUp is working on the development of a metal Additive Manufacturing system whose capabilities are built on the foundation of its FormUp 350.

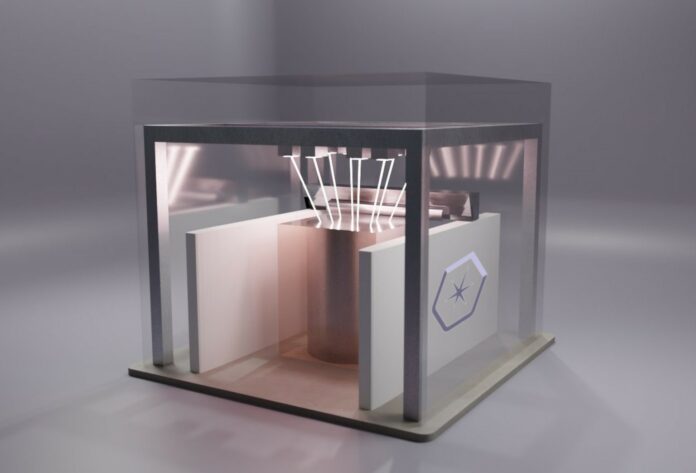

The project called “MASSIF” (Metal Additive System, Sustainable, Industrial, Eco-Friendly) aims to meet the demand for large-format metal Additive Manufacturing applications achieved with Powder Bed Fusion (PBF); applications whose size can reach up to1.5m x 1.5m x 2m.

This project’s team seeks to enhance productivity, eliminate additional costs, and meet various sustainability criteria. MASSIF will enhance the existing features of AddUp’s FormUp 350. With improved throughput and precision, the FormUp 350 can ensure serial production across different sectors including aerospace, medical, and other high-precision industries.

According to AddUp, MASSIF will boast a 300% productivity gain with a 12x greater build capacity than the earlier versions of the company’s metal 3D printers, lowering the part production cost by 50 to 70%. It will integrate many green features including decarbonated energy usage and less than 10% powder waste.

MASSIF stresses the importance of a responsible manufacturing model via various collaborations with industry experts. These partners include Cailabs, ISP Systems, Dassault Systèmes, and Vistory. They will bring their expertise in laser beam shaping solutions, laser beam, virtual twin experience, confidentiality, and integrity of manufacturing data.

AddUp CEO, Julien Marcilly says, “The association of the best experts, each in their field allowed us to launch the MASSIF project. This technological leadership in large-scale metal 3D printing will enable us to meet the challenges of energy transition and productivity for aeronautics, defense, and space players, always in a co-design approach by AddUp with its clients.”

This MASSIF prototype will be first installed at CETIM‘s Printing Bourges center. As AddUp continues developing MASSIF, the metal 3D printing landscape is awaiting a step forward in productivity, sustainability, and cost-effectiveness.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.