Cholesteric liquid crystals, a man-made material with properties between liquids and solid crystals, can mimic the colors of butterfly wings. Liquid crystals are used in televisions and smartphones, but future applications for healthcare sensors or decorative lighting are difficult as the materials can’t be used in advanced, rapid production methods like 3D printing. The materials are not viscous enough to make stable, solid structures, and it’s difficult to align the molecules to produce specific colors.

TU/e researchers have solved these issues by developing a new light-reflective liquid crystal ink that can be used with existing 3D printing techniques. The new research has been published in the journal Advanced Materials.

In nature, iridescent materials, which exhibit a color change when viewed from different angles, can be found in butterfly wings and in nacre (or mother of pearl) in the inner shell of mollusks.

A man-made version of these natural materials is cholesteric liquid crystal, which has already been used as ‘smart’ materials in light reflectors, switchable windows, and tunable solar energy collectors.

For healthcare applications in soft wearable sensors or decorative lighting, cholesteric liquid crystals are ideally suited. Until now though, an easy way of producing these materials and making devices from these materials has been lacking.

A new ink solution

Researchers from the department of Chemical Engineering and Chemistry at TU/e in collaboration with TNO, DSM, Brightlands Materials Center (in the DynAM consortium), and SABIC have created a nature-inspired liquid crystal elastomer-based ink that can be 3D printed on a surface via Direct-Ink-Writing (DIW). Lead author for the study is PhD candidate Jeroen Sol, with Albert Schenning and Michael Debije from the Stimuli-responsive Functional Materials and Devices (SFD) group heading the research project.

“DIW is an extrusion-based 3D printing approach where an ink is dispensed from a small nozzle onto a surface on a layer-by-layer basis. Current cholesteric liquid crystal inks cannot be printed with DIW, so we created a liquid crystal ink compatible with DIW,” says Sol.

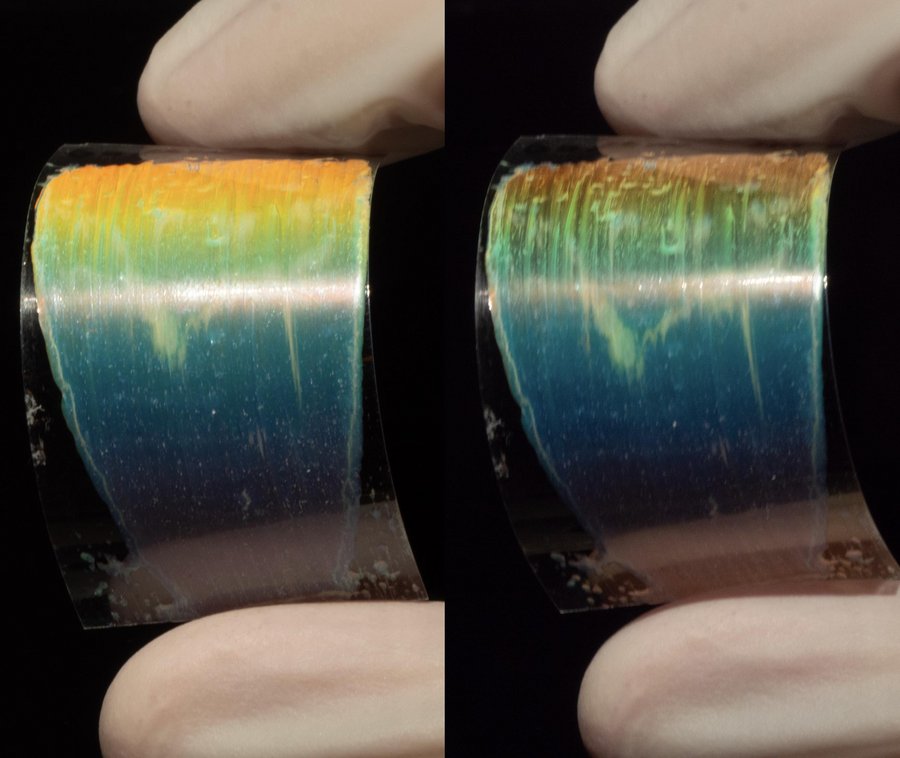

The new liquid crystal ink has several key properties. First, the light reflective properties of the ink rely on the precise helical alignment of molecules throughout the material which requires fine tuning of the printing process. Second, the molecules in the ink can self-assemble into such structures that display colors similar to natural iridescent materials, like those in butterfly wings. Third, the new ink has greater viscosity than previous inks, which makes it suitable for DIW printing.

Finally, the new ink is novel, easy to make, easy to process, and based on materials previously developed by the SFD research group at TU/e for light-reflective coatings, which help make it suitable for 3D printing.

Printing with butterfly wings

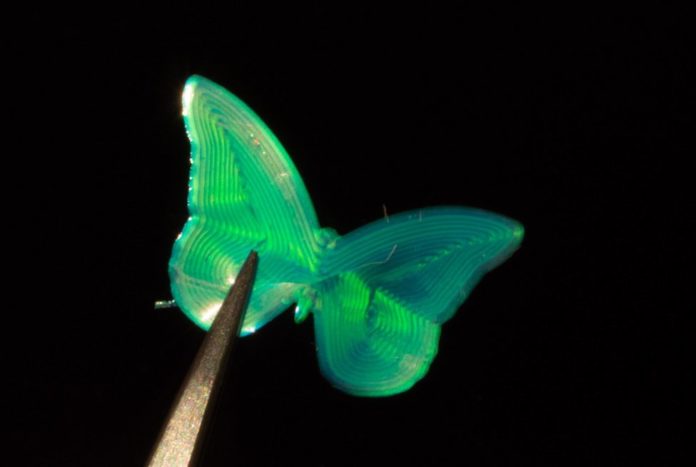

“To successfully print the new ink with DIW, we varied parameters like print speed and temperature. And to get the ink to print properly, we also made an ink containing low-molecular weight liquid crystals,” notes Sol. Rather impressively, the researchers were able to use the new ink to print synthetic butterfly wings!

Much to the surprise of the researchers though, they were also able to control the nanoscale molecular alignment very accurately by varying the print speed. This allowed the researchers to have greater control over the appearance and light reflecting properties of the material. “Traditionally, this level of control is only possible with very specialized fabrication devices, so to do this with the new ink and DIW 3D printing is a real breakthrough,” says Sol.

Future applications

Given that the new liquid crystal ink can be printed with DIW, it could be used in future printing procedures for personalized medical devices such as thin wearable biosensors that interact visually and colorfully with the wearer.

“What’s more, the combination of our new ink and DIW can be used to print the specialized optical structures needed for augmented reality headsets where real-life and artificial images are seamlessly combined,” says Sol excitedly. “The new materials could find their way into the HoloLenses of the future – now that would be something extraordinary!”

You may read the full research here.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com