As part of a research project conducted at the Zurich University of the Arts, augmented reality and 3D printing are being examined as potential teaching materials of the future.

The research associate of the group Knowledge Visualization at the Zurich University of the Arts (ZHdK), Jonas Christen, is developing immersive teaching materials based on Augmented Reality (AR).

In the first field test, secondary school students are to gain a deeper understanding about the working methods of archaeology. This is not only done digitally, however: «A pure AR application bears the risk that the students are distracted by the fascination for the medium and absorb little information», says Christen.

With augmented reality glasses, the students can experience each step of the process three-dimensionally and animated on the surface of the workbook, in order to gain a better sense of the archaeologist’s approach. The old medium of paper and the new medium of AR has been complemented by the use of 3D printing.

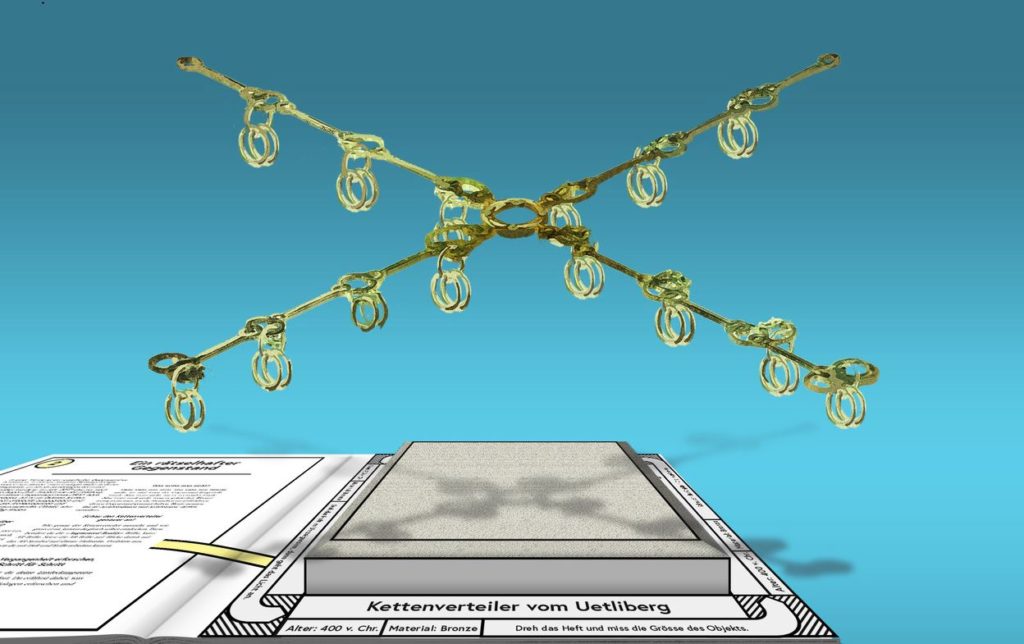

This project is specifically about a bronze object consisting of several chains and rings – a so-called chain divider – which was probably used as an ornament for horses. The find dates back to 400 BC and was uncovered in 2014 at the Uetliberg, a mountain near Zurich. With such a highly complex piece, 3D printing soon proved to be the only viable manufacturing method to create a true-to-life replica.

«The 3D printed reconstruction serves as a visual object for the students to experience the dimensions of the find, but can also provide archaeologists with new insights about its possible use», says Christen.

The chain divider was subsequently 3D printed with the durable PA12 nylon material on the Sintratec S2 system. Selective Laser Sintering (SLS) proved to be the ideal choice for Jonas Christen: «The Sintratec technology allows us to reproduce the extremely fine aspects of the object in great detail», he points out.

«The accuracy, robustness and haptics of SLS printing were important factors for us.» In the first field test, the SLS chain inspired the students and successfully contributed to the transfer of knowledge. Thus, the exciting combination of augmented reality and 3D printed parts could very well find its way into future classrooms.

«The Sintratec technology allows us to visualize the delicate features of archaeological objects in great detail.»

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com