A partnership between Nano Dimension and research centers in Canada and France led to an advance in biomedical research and medical devices.

As you may know, Nano is first known as a supplier of Additively Manufactured Electronics (“AME”). The company now holds multiple hats following the acquisition of several companies it achieved. One of these hats consists in being a supplier of micro-3D printing through Fabrica.

As a matter of fact, this milestone occurs after the expansion of its micro-AM product line.

The study

The study centers around the accurate recording of neuronal activity in mice, with the aim to elucidate the neuronal circuits and mechanisms involved in the processing of somatosensory information.

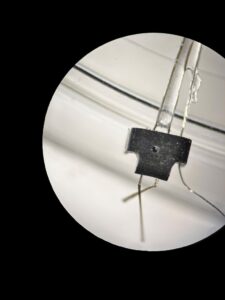

According to the research team, which comprised researchers from three leading institutions, small or micro medical devices for research project purposes pose significant challenges in production due to their size, dimensional requirements, and intricate features. In this instance, the team needed to design a miniature brace capable of securely holding two electrodes on the vertebra of the mouse. To date, limited attempts have been made to explore the electrical activity of dorsal horn neurons in awake animals, which presented its own challenges for the team.

“Recording the electrical activity of neurons in the spinal cord of a conscious animal is not easy, mainly due to the movements induced by walking and breathing of the mouse, as well as the accessibility of the area in question,” explains Louison Brochoire, a PhD student at the University of Bordeaux in France.

“For this project, we needed the brace to allow movement of the animal while firmly securing and stabilizing electrodes that were inserted into very minute holes,” adds Brochoire, who worked under the supervision of professors from Bordeaux’ Institut des Maladies Neurodégénératives, as well as from the CERVO Research Center and University of Laval in Québec, Canada.

Mindful that traditional manufacturing methods would involve a lengthy struggle to produce a device that could effectively stabilize electrodes in place while maintaining accuracy and functionality, the team partnered with Nano Dimension to find an alternative solution.

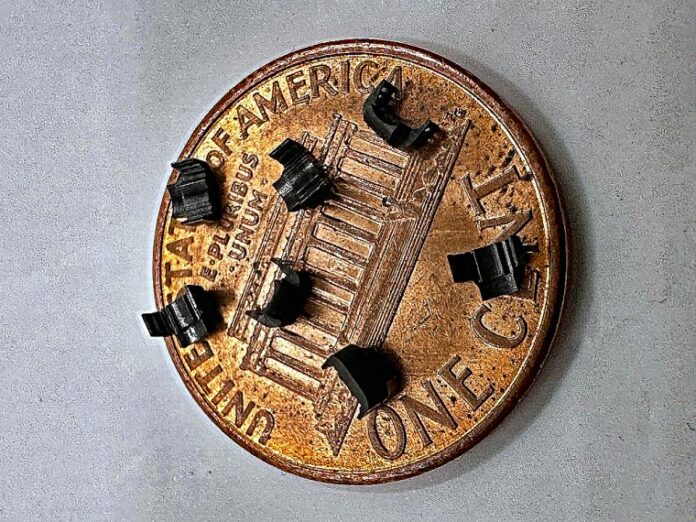

The intricacy of the design challenge required precise dimensions, including 110µm holes for electrodes in a part that was merely 2.7mm in width. This saw Nano Dimension deploy its Fabrica micro-3D printing technology to fabricate the required brace.

The Fabrica 3D printers can produce accurate and functional parts with tight tolerances and a pixel size as small as 4µm and a layer height of between 1-10µm. Due to its clearance for cytotoxicity, and the fact that it is not toxic for human cells, the Fabrica Medical M-810 material was the perfect fit for the device. This provided a functional part for the team to use in their research within just one week.

For the research team, the result met their requirements exactly. “The ability to create such precise and minute holes within the brace was critical,” says Brochoire. “This design attribute helped to minimize artifacts caused by breathing and movements of the animal, which would interfere with our electrical signal, complicating the analysis of results.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com