— And how CERIA helps achieve the minimum number of iterations during manufacturing. 3DCeram will be exhibiting at Formnext, in Hall 11, C68.

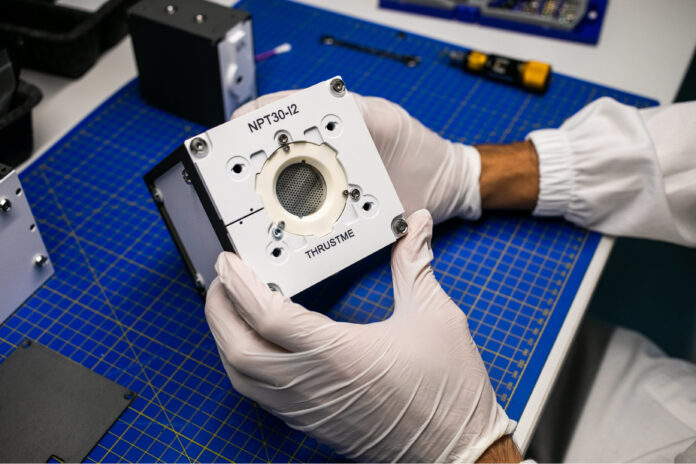

Five years ago, as part of a closed Technology Development Element (TDE) activity conducted between the European Space Agency and space company Anywaves, the latter was tasked with producing four antennas to test and qualify 3D ceramic technology structures. Anywaves delivered two elliptical antennas with a filled lattice structure and two truncated patch antennas with an empty lattice structure.

The antennas exceeded expectations during demanding environmental tests, showcasing strong mechanical and thermal properties, especially the patch antenna with the empty lattice.

A few months later, we learned that Anywaves had successfully manufactured these satellite antennas using 3DCeram’s three-step ceramic 3D printing approach. While the experience was a success, it highlighted one crucial factor for this application: the importance of selecting the right technical ceramic material.

Fast forward to today. With a growing focus on SLA 3D printing and the push toward industrializing large, monolithic parts, one question emerges: How do technical ceramics help meet the challenge of producing large, high-performance 3D printed parts—manufactured in a single piece?

Thanks to their favorable strength-to-weight ratio, resistance to high temperatures, and chemical stability, technical ceramics are opening new possibilities for space transportation and exploration. To better capture their advantages, the 3DCeram’s team suggests looking into properties that cannot be found in polymer and metallic materials:

“Technical ceramics are distinguished by exceptional properties, including high thermo-mechanical resistant, chemical inertia, and more.

As a general rule, ceramics are stiffer, harder, and more resistant to oxidation than metals. All these properties combine to make ceramics an exceptional material.

For aerospace applications, the most sought-after ceramics are those known as thermostructural (silicon nitride, aluminium nitride, etc.). They are resistant to thermal shock and have a very low coefficient of thermal expansion. They are resistant to radiation and chemically inert, among other things.

To play with perspective: the dust we might one day find on other planets is, in many ways, similar to ceramic material. Take lunar regolith, for example—a material we’ve replicated on Earth to match the composition of Moon dust. We’ve already tested it with 3D printing, and it worked—we successfully printed parts! This opens the door to a bold possibility: one day, we could send 3D printers to other planets to manufacture tools and structures directly from local materials.”

In space applications in particular, technical ceramics are recognized for their ability to radiate heat. The heat radiation rate is linked to the fourth power of the surface temperature. This means it becomes the principal heat transfer mechanism at temperatures higher than 1000 degrees Kelvin (≈ 727°C). Given such extreme condition, the list of technical ceramics that are ideal for producing large and mission-critical parts is quite exhaustive. The 3DCeram team includes in that list two oxide ceramics (alumina and zirconia) and two non-oxide ceramics (silicon nitride – Si₃N₄ – and aluminium nitride).

| Read more: Technical ceramics: Current advancements & limitations in multi-material 3D printing |

These materials can be processed by Stereolithography (SLA), when adapted for technical ceramics using photopolymerizable ceramic slurries, and enable the high-precision additive manufacturing of complex parts. The 3DCeram team explains why they are compatible with ceramic SLA and why they are particularly well suited for space and defense applications:

“Alumina is used for structural components in satellites, thanks to its corrosion resistance, thermal stability, and excellent dielectric properties. SLA technology enables the creation of intricate internal geometries without the need for assembly, reducing potential weak points.

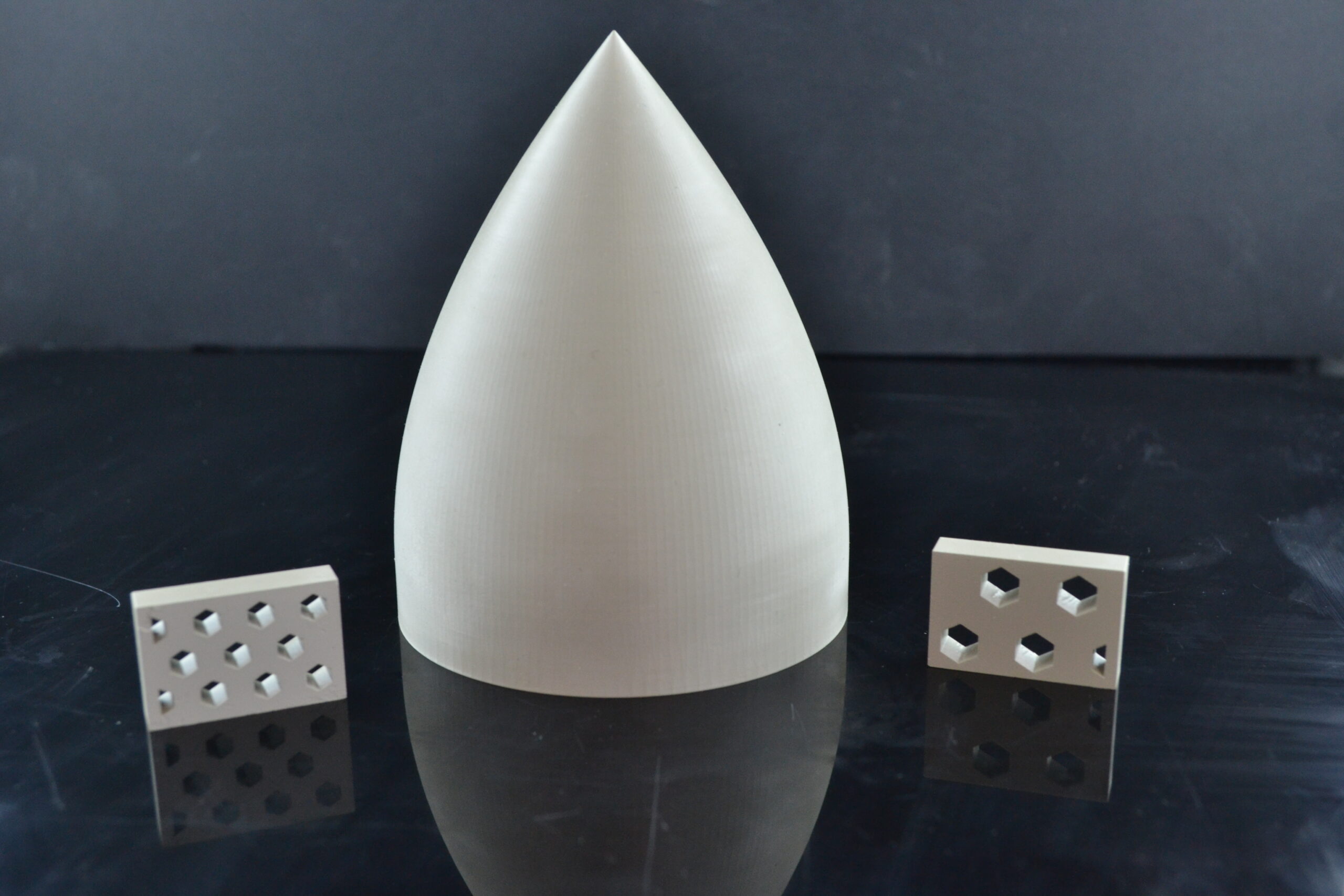

Silicon Nitride (Si₃N₄) is ideal for parts exposed to thermal shocks. Its high mechanical strength, excellent fracture toughness, and wear resistance make it a top candidate for such applications. 3D printing allows the production of lightweight components with integrated features for improved performance, such as mirrors, structural parts, and radomes.

Zirconia offers high mechanical strength, low thermal conductivity, and is well-suited for dynamic mechanical loads. Shaping Zirconia with SLA enables exceptional resolution.

Aluminium Nitride is valued for its high thermal conductivity, electrical insulation, and thermal and chemical stability, as well as its compatibility with silicon. It is commonly used in substrates for high-frequency circuits, thermal barriers, and optoelectronic components.”

Despite these properties, our coverage reveals that the number of clearly identified viable applications for 3D printed technical ceramic final parts remains limited. The obvious reason that may explain this is the fact that ceramics are a niche used with a niche technology – AM. Yet there are also cost and manufacturing considerations to take into account.

According to 3DCeram, their expensive cost urges their use in applications where polymers and metals do not perform well. This is unfortunate, as the industry should prioritize the needs of specific applications first.

At the manufacturing level, as with most materials and AM processes, technical ceramics require experience to achieve parts with the minimum number of iterations. To address this issue, the 3DCeram team has developed CERIA, a software solution powered by AI. They explain:

“CERIA helps reduce the number of iterations to achieve a single successful run. Manufacturers want a straightforward process and “ready-to-run” 3D printers — and that’s exactly what CERIA provides, dramatically shortening the learning curve.

While ceramics are exceptional materials, producing them requires extensive expertise that can only be gained through experience. This is precisely the expertise 3DCeram has developed over years of part production since its founding, and which informs the data behind CERIA.”

Using CERIA in large space and defense applications

Unveiled at Formnext 2024, CERIA acts both as an assistant and a real-time pilot throughout the additive manufacturing process. Whether you have a small batch or a massive number of parts in the printing platform, the software solution works the same way by automatically adapting the printing time according to the design.

“During the pre-production phase, CERIA Set plays a crucial role as a smart assistant. It ensures that the part design is printable, and suggests improvements where necessary. From the initial design stage to the preparation of the build platform, CERIA Set guides the engineer through each step to create a fully “ready-to-print” setup.

It analyzes the positioning of parts on the build platform, identifies opportunities to optimize packing density or print time, and then automatically generates customized printing parameters based on this analysis—ready to be sent to the printer.

Once the print job begins, CERIA Live takes over. It monitors the print in real time, analyzing the last three printed layers and using this data to adjust the next five. For instance, it can dynamically accelerate or slow down the recoater to maintain optimal printing conditions. This active process control secures the print run, reduces the risk of failure, and eliminates the need for multiple costly iterations—ultimately saving time, material, and production cost.

From the beginning, CERIA was designed to simplify and secure technology transfer to our customers. It significantly shortens the learning curve compared to traditional approaches and supports consistent, high-quality results even for new users.

Today, we are proud to be the only company in the ceramic additive manufacturing market offering this level of AI-driven process assistance—and we’re convinced that this approach represents the future of advanced manufacturing,” the 3DCeram team points out.

Integrating CERIA into a 3DCeram’s SLA production environment can help foster the development of applications beyond antennas. Some of these applications may include heat shields, thermal protection systems, structural parts, nozzles, and thruster parts for propulsion systems.

The question is: how big a 3D printed part can be?

“We have developed a range of 3D printers that support everything from development to full production. At the heart of this product strategy is the C3601 ULTIMATE — our largest printer with a build platform measuring 600 × 600 × 300 mm”, 3DCeram states.

“Using this printer, we produced a semiconductor part that nearly fills the entire build platform — the green part has a diameter of 550 mm. This printer is currently the only ceramic 3D printer on the market capable of handling parts of this size, enabling the production of a single large component, multiple mid-sized parts, or numerous smaller ones,” the company adds.

“Using this printer, we produced a semiconductor part that nearly fills the entire build platform — the green part has a diameter of 550 mm. This printer is currently the only ceramic 3D printer on the market capable of handling parts of this size, enabling the production of a single large component, multiple mid-sized parts, or numerous smaller ones,” the company adds.

In addition to the C3601 ULTIMATE, the company also includes in its portfolio the C1000 FLEXMATIC. With a 320 x 320 x 200 mm build volume, this 3D printer is worth keeping in mind when exploring industrial-scale production.

In addition to the C3601 ULTIMATE, the company also includes in its portfolio the C1000 FLEXMATIC. With a 320 x 320 x 200 mm build volume, this 3D printer is worth keeping in mind when exploring industrial-scale production.

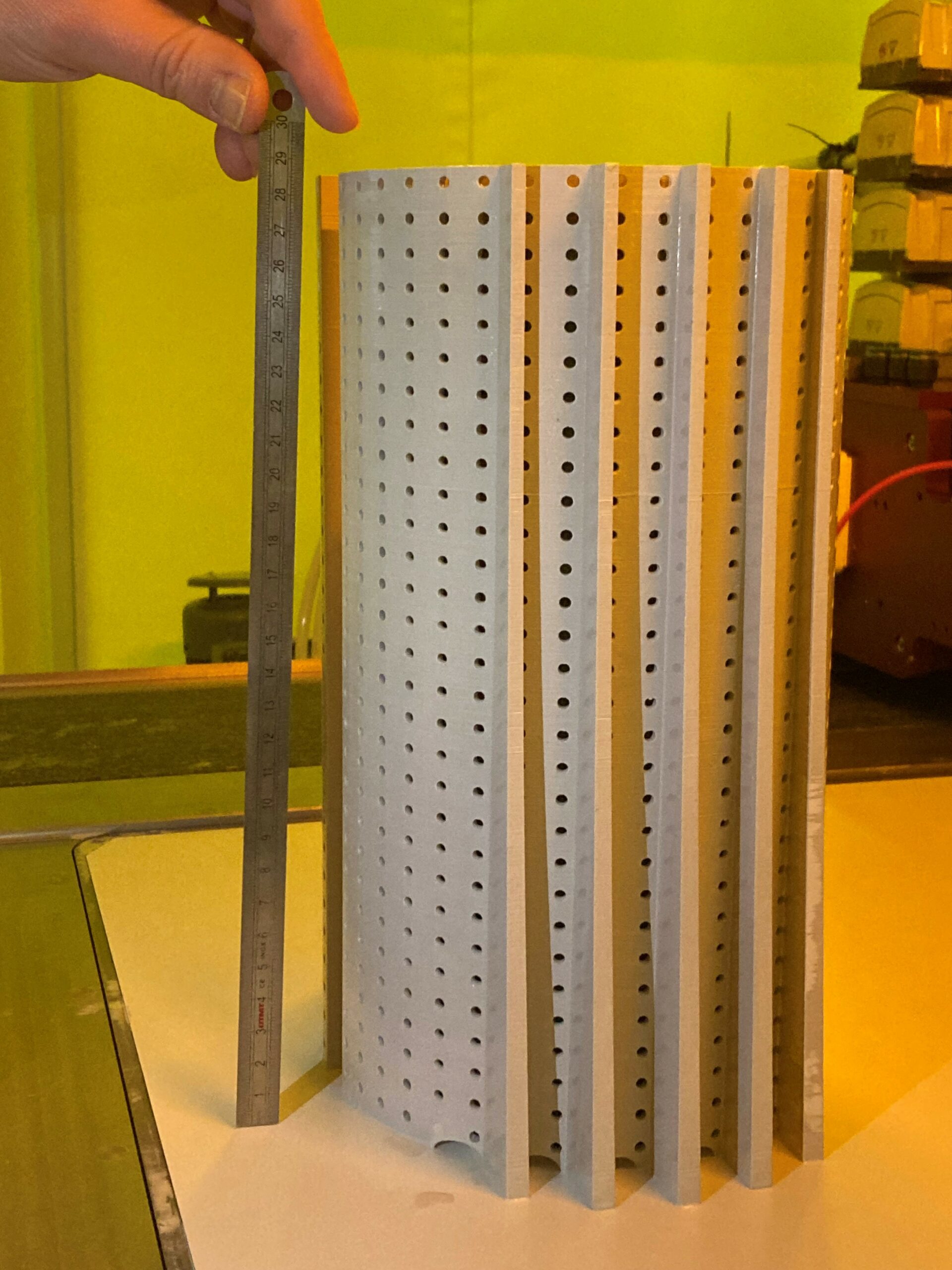

For the defense sector, the company recently printed six large pieces in a single run. Each of them measures 290 mm in height and 190 mm in diameter. Details of the manufacturing process reveal that:

“These parts were printed on the C3601, currently the only ceramic additive manufacturing printer capable of handling such a production run. The main challenge was the material—it wasn’t part of our standard portfolio. We had to develop a custom slurry using the customer’s powder and fine-tune the printing parameters. Such development typically requires multiple iterations; for this project, we completed three production runs before achieving a satisfactory result.

This success was made possible thanks to CERIA, our in-house artificial intelligence system. During pre-production, CERIA Set assisted our engineers by optimizing part design and defining optimal printing parameters. Then, during printing, CERIA Live took over, monitoring the process in real time. It analyzes data from the last three printed layers and uses this information to predict the next five layers, enabling real-time adjustments for improved accuracy and consistency.”

This success was made possible thanks to CERIA, our in-house artificial intelligence system. During pre-production, CERIA Set assisted our engineers by optimizing part design and defining optimal printing parameters. Then, during printing, CERIA Live took over, monitoring the process in real time. It analyzes data from the last three printed layers and uses this information to predict the next five layers, enabling real-time adjustments for improved accuracy and consistency.”

Concluding thoughts

Unlike other technologies that rely on bottom-up approaches and face significant challenges at larger scales, SLA 3D printing uses gravity to its advantage. With its top-down printing approach, the technology can provide superior stability and reduce the risk of part deformation or detachment during the build.

Managing such gravity becomes pivotal in a large production approach where weight plays a key role. Beyond weight, 3DCeram’s SLA ceramic printing brings other key considerations to the table: scalability and repeatability.

The use of CERIA refocuses the debate on the importance of automation in today’s industrial production and positions 3DCeram’s technology as one that is particularly well suited for industrial environments where repeatability, throughput, and process control are critical.

“We design our entire process with industrial needs at the forefront. We fully understand that manufacturers—whether in defense, aerospace, or other sectors—aren’t looking for experimental setups. They want a ‘push-button,’ ready-to-use 3D printer that is technically reliable, consistent in quality, and ultimately cost-effective.

This applies not only to the production of large parts in series but also to small and medium-sized components. The key factors are repeatability, process stability, and scalability, all while ensuring a high return on investment.

That’s why we developed our own artificial intelligence, CERIA, and why we continually push the boundaries of automation. Every improvement we make is focused on simplifying the user experience while raising the bar for industrial performance. This is the mindset we bring to our work every day—and it’s what sets 3DCeram apart,” the company concludes.

This content has been produced in collaboration with 3DCeram. Read all news on 3DCeram here. All images: credit of 3DCeram.