A recent dossier on how AM and the semiconductor industry can help each other, reveals that material selection and qualification are a major challenge for semiconductor equipment (SCE) manufacturers. AM materials that could meet the stringent performance requirements of semiconductor devices could be challenging to identify, as they should be able to deliver electrical, thermal, and mechanical properties – all of which are crucial to unlocking the potential of AM in semiconductors.

Aware of these hurdles, AM technology providers are working steadily to address them. Ceramic 3D printing expert 3DCeram is the latest to mark a milestone, announcing the compatibility of aluminum nitride (AlN) and silicon nitride (Si₃N₄) with its industrial SLA 3D printer, the C1000 FLEXMATIC.

Although both materials also show strong potential in aerospace and optics, we believe they underscore the suitability of SLA 3D printing as an ideal production candidate for the semiconductor sector. The following article explores how, with a particular focus on the unique capabilities of these materials.

In an industry where many semiconductor and aerospace applications often showcase the capabilities of metal 3D printing, LPBF in particular, the ability to manufacture with aluminum nitride (AlN) and silicon nitride (Si₃N₄) demonstrates the potential of technical ceramics to address challenges that metals and polymers cannot.

In this particular case, aluminium nitride (AlN) and silicon nitride (Si₃N₄) go one step further, as they can solve problems that even more common ceramics cannot.

How?

It all comes down to properties. In semiconductor, aerospace, and optics applications, AlN and Si₃N₄ can outperform more common ceramics due to their strong performance in thermal conductivity, thermal expansion, mechanical strength, and electrical insulation.

As we are aware of the strengths of materials like alumina and zirconia in other applications, we do not aim to compare these materials with AlN and Si₃N₄, but rather to demonstrate the advantages of AlN and Si₃N₄ in these specific applications.

According to 3DCeram, the addition of nitrides to its materials’ portfolio is particularly significant. Aluminium nitride and silicon nitride are already established in high-value applications, but their full potential has often been limited by manufacturing constraints.

- AlN combines high thermal conductivity, electrical insulation, and low thermal expansion. These properties make it ideal for thermal management in electronics, where components must dissipate heat without losing dimensional stability.

- Si₃N₄ is valued for its fracture toughness, resistance to thermal shock, and long service life under mechanical or chemical stress. Its robustness has made it a reference for structural parts in aerospace and defense.

What additive manufacturing brings to the table is the ability to merge these intrinsic properties with design freedom: lightweight geometries, internal channels, or integrated features that traditional processes struggle to achieve.

Why SLA 3D printing in particular?

Using technical ceramics with SLA 3D printing remains, in my view, one of the most underrated technology combinations when considering aerospace applications. Yet, 3DCeram’s SLA technology continues to prove its value in highly demanding environments.

| Read more in this FOCUS: Moving toward industrialization with 3DCeram’s ceramic 3D printing

In the May/June edition of 3D ADEPT Mag: FOCUS | 3DCeram Sinto on why specific technical ceramics are best suited for large, 3D printed space parts |

This may be explained by the fact that scaling ceramic AM has long been hindered by two challenges: operator dependency and process consistency. 3DCeram addresses these challenges by integrating automation and its AI-powered software CERIA into the C1000 FLEXMATIC’s manufacturing workflow.

With a 320 × 320 × 200 mm build area, the C1000 FLEXMATIC 3D printer offers the flexibility to manufacture parts of different sizes while maintaining the same high level of precision. Its semi-automated modules simplify workflow and reduce downtime.

By recovering and reconditioning unused slurry, the integrated recycling unit also minimizes waste and supports continuous production runs; features that make the machine better suited to series manufacturing than conventional lab-scale printers.

Unveiled at Formnext last year, the CERIA AI engine automatically generates optimized parameters, making it easier for manufacturers to achieve repeatable quality.

A closer look at key applications enabled with AlN and Si₃N₄ : heat sinks and telescope structures

Heat sinks are essential in both semiconductor and aerospace applications for thermal management, while telescope structures are primarily a concern in aerospace engineering.

In semiconductors, heat sinks cool power devices to prevent failure. In semiconductor processing equipment, heat sinks are positioned beneath the wafer to ensure efficient thermal management during deposition or etching. To perform reliably, they must combine conductivity, mechanical stability, and resistance to plasma environments.

In aerospace, they are used in electronic components and for structures like telescope bodies to maintain performance under extreme temperatures.

The combination of AlN with 3DCeram’s SLA 3D printing helps deliver components with improved heat dissipation and optimized geometries.

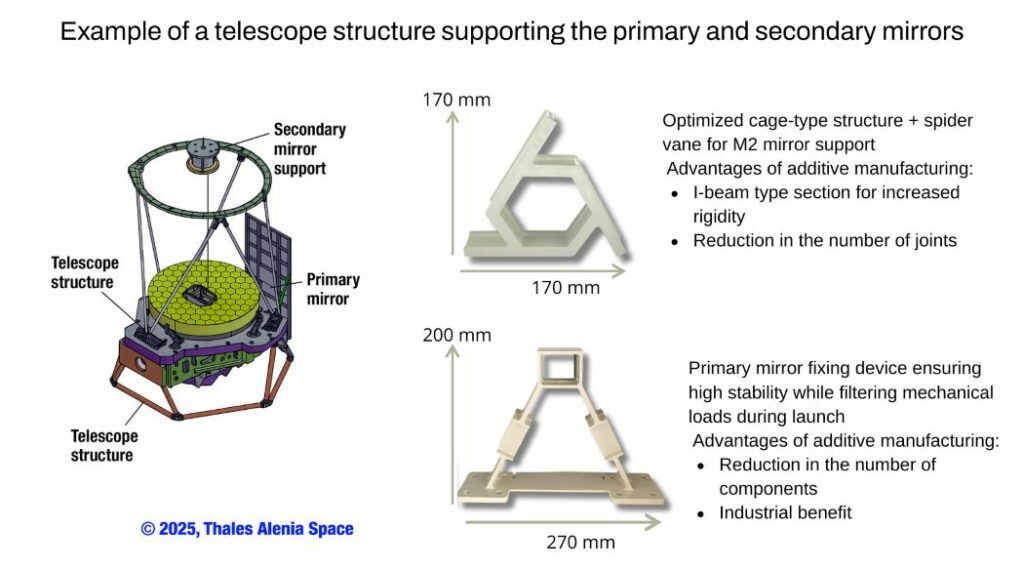

According to 3DCeram, in aerospace and optics, Si₃N₄ has already been adopted for structural components in telescope assemblies. For example, in Aliéna telescopes, mirror support structures need to withstand launch stresses while preserving optical stability in orbit.

Thanks to additive manufacturing, these parts can be redesigned as cage-like or spider-vane geometries that are lighter, stiffer, and easier to integrate. Here again, AM extends what can be achieved with this high-performance ceramic.

If you ask me, is the advantage of AlN and Si₃N significant enough? I would say YES – without any doubt!

In thermal management applications, by combining AlN with AM, it is not only about using AlN’s intrinsic high thermal conductivity, it is about multiplying its effect with geometry that couldn’t be achieved otherwise.

In optics applications, it’s about delivering better transparency and thermal stability when pairing AlN or Si₃N₄ with AM.

Overall, these applications increasingly demonstrate the growing use of SLA 3D printing in production applications:

“The move from prototyping to production in ceramic AM is gradual, but the direction is clear. Manufacturers are asking for machines that deliver repeatability, materials that meet demanding specifications, and workflows that align with industrial practices.

By integrating AI-guided process control, semi-automation, and advanced nitrides, the C1000 FLEXMATIC positions itself as a platform for this transition. It demonstrates that ceramic AM is no longer a laboratory curiosity but a technology capable of producing real parts for real industries,” 3DCeram states.

Looking ahead

For sectors such as semiconductors and aerospace, where every component must balance performance with cost efficiency, the availability of nitrides through additive manufacturing could mark an important step. The C1000 FLEXMATIC shows how this balance can be achieved — combining the design freedom of AM with the reliability and scalability industry demands.

| Those wishing to explore these topics further can connect with 3DCeram Sinto via 3dceram.com.

|

This content has been created in collaboration with 3DCeram.