CoreTechnologie has released a new version of its 3D printing Software 4D_Additive. The latter now works with artificial intelligence algorithms to achieve an optimal heat distribution. The addition of this new technology ensures a better arrangement of parts in the build space during nesting.

The announcement follows the recent addition of new functionalities such as the use of exact B-REP CAD data of all common native and standard formats for the preparation of 3D printing jobs as well as the ability to generate repaired and optimized STEP models.

The new nesting function of the renowned 4D_Additive software from CoreTechnologie uses artificial intelligence (AI) for the first time to automate intelligent behavior and machine learning. The new technology simulates certain human decision-making structures based on the programming and by this means the computer independently processes complex tasks in the area of so called nesting.

Optimized Component Nesting

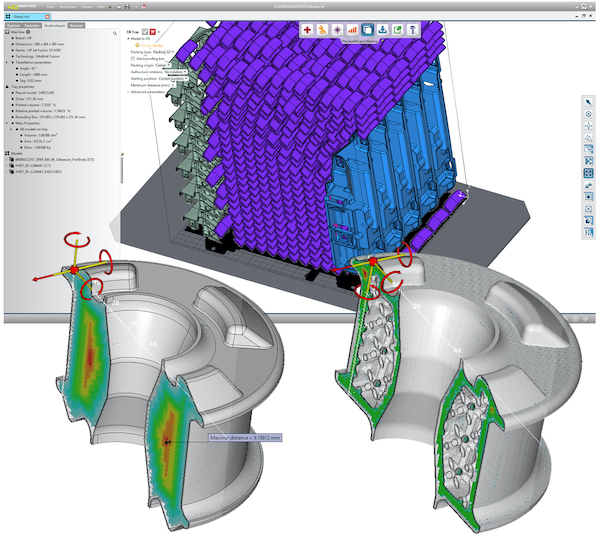

With its new “pack and optimize” strategy, the nesting module of the latest 4D_Additive software version is able to ensure both maximum filling of the installation space and even distribution of the mass to be printed, thus ensuring the most constant possible slice surfaces. The advanced program uses AI technology and imitates the behavior of an experienced user by automatically filling empty areas in the packaging space after pre-positioning. This has the advantage that even build spaces that are not fully loaded are filled evenly and without so-called heat nests. The printing results are maximally optimized by the even distribution of the components.

Intelligent Additional Functions

In addition to intelligent nesting, further functions are available to optimize heat distribution within the components. An analysis to determine so-called massive zones shows problematic areas with large material volumes and displayes these zones graphically in a highly visible manner.

These zones then can be hollowed out with a few mouse clicks using the hollow and lattice functions and, if necessary, reinforced with an internal support structure. To remove powder from the inside of the hollowed parts, holes and the appropriate lids can be created automatically.

As a reminder, for the preparation of 3D printing data, the 4D_Additive tool has CAD data interfaces for all B-Rep native and standard formats as well as the common 3D printing formats such as STL and 3mf.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com