ZW3D has announced the availability of VoluMill, which is integrated in its software solution. Powered by the high-speed roughing technology, once the capacities of both software are combined, the supplier of CAD/CAM solutions is capable to reduce cycle time by 70%.

VoluMill

VoluMill

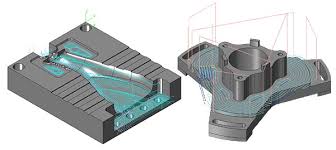

VoluMill combines optimal milling paths and maximum material removal with minimized machining times. The built-in technology does not require extra installation, making it very convenient without disrupting workflow.

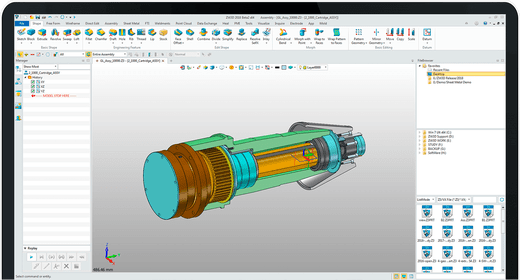

Using the all-in-one CAD/CAM solution for the whole process of product development, ZW3D customers can manage 3D data & its transition, finish design and manufacture work on one platform.

When integrated into ZW3D, the toolpath option uses a constant & high-speed toolpath, leading to an optimized CNC program.

Besides, the powerful, high material removal rate capabilities can help customers create the most efficient toolpath for a wide variety of milling part types in your workshop. Consequently, it’s proven to increase cutting tool life by up to 800%.

“We appreciate that VoluMill is tightly integrated with ZW3D. The task-focused toolpaths strategy performs much better than the traditional one. ZW3D will significantly help users increase productivity by 50% or more,” said Mason Liu, Vice President of ZWSOFT.

Available in 2-3 Axis, VoluMill for ZW3D is perfect for the airframe, automotive, mold & die, medical, machinery component, and consumer-products markets, for all roughing needs on free-form or prismatic parts. The result is increased efficiency and utilization of machines, tools, labor and materials.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com