Thermwood achieves a one-day record by receiving 32 Additive Manufacturing patents for its LSAM machines

Sometimes, every good news – you did not expect – you receive when Christmas is around the corner is often considered as the most amazing Christmas gift or Christmas miracle. Obviously, that’s something you are eager to tell everyone – especially if you are a company.

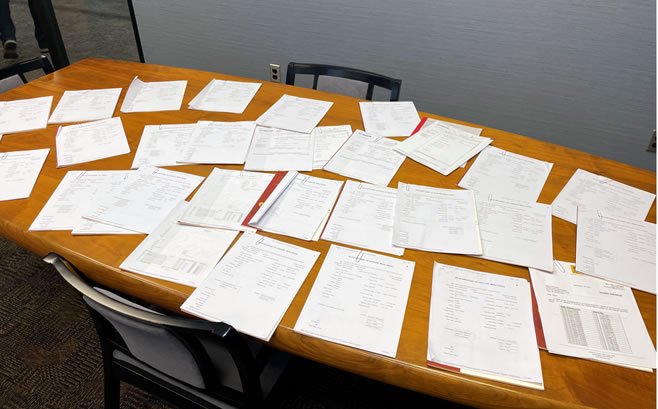

Imagine now Thermwood’s surprise, enthusiasm and gratitude when the team received 32 AM patents. The company regularly files patent for its Large Scale Additive Manufacturing – LSAM large format additive systems. However, with the Covid-19 pandemic, so the modus operandi had changed and the company had only received electronic copies of these patents.

I now imagine that, seeing the official hard copies certainly arouses the same feelings of pride – or even more – an editor has when they receive a print copy of the digital mag, they have been working for, for a long time.

When 3D ADEPT Media invited Thermwood’s Dennis Palmer in an Opinion of the Week, the Vice President of Sales told 3D ADEPT Media the company had over 55 patented features (and over a dozen more pending) for its LSAM technology. This was two years ago. The addition of these new patents brings the total number of patents the company has been granted to 87, making the organization the first one to hold the largest number of patents to date in large format AM.

Furthermore, beyond the fact that a patent ensures the protection of your invention regardless of whether it is a product, a design, or a process, it recognizes the potential of your invention.

The developer of very large format 3D printing hardware and services with composite chopped Fiber Reinforced Polymer (FPR) pellet materials enables the production of applications across the aerospace, transportation, heavy equipment, foundry industries – and also the production of large decorative structures.

Those applications include for instance, aerospace patterns, moulds and tooling, heavy equipment foundry patterns, bus chassis, large valve body foundry patterns and trim tooling. However, our favourite application so far, remains the Al Davis Memorial Torch, a 93-foot (28.3464m) commemorative structure to honor the long-time franchise owner of the Las Vegas Raiders.

“Thermwood offers this unique patented technology on a wide variety of equipment, the largest, most diverse product offering of its kind available today. It includes a broad selection of machines, including single and dual gantry, fixed and moving table configurations, with both print-only and print-and-trim systems, from 5 by 10 foot to 20 by 60 foot print envelopes. We are working on even larger machines but that’s for another day. The primary focus of the patented LSAM technology is to reliably and repeatedly produce the highest quality, best fused, most homogeneous printed structures possible from a variety of reinforced thermoplastic polymer composites including those intended to operate at elevated temperatures. Although it is nice to have been granted these patents, it is even nicer to finally have the official hard copies in hand”, the company notes in a press communication.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com