As a production floor manager, having quick access to crucial manufacturing information is essential: “Which jobs are delayed? How many items can we ship today? Which resources are overloaded?” To get these answers, you might find yourself rushing to an operator, who, in turn, will likely consult an Excel sheet to provide that information.

Interestingly, those who would not like to rely on Excel sheets are likely to rely on an ERP system to get a practical and quick overview of their production operations. The problem is Additive Manufacturing (AM) production floor managers cannot rely on such software solutions. And that’s a gap the experts at nPower Technologies have filled.

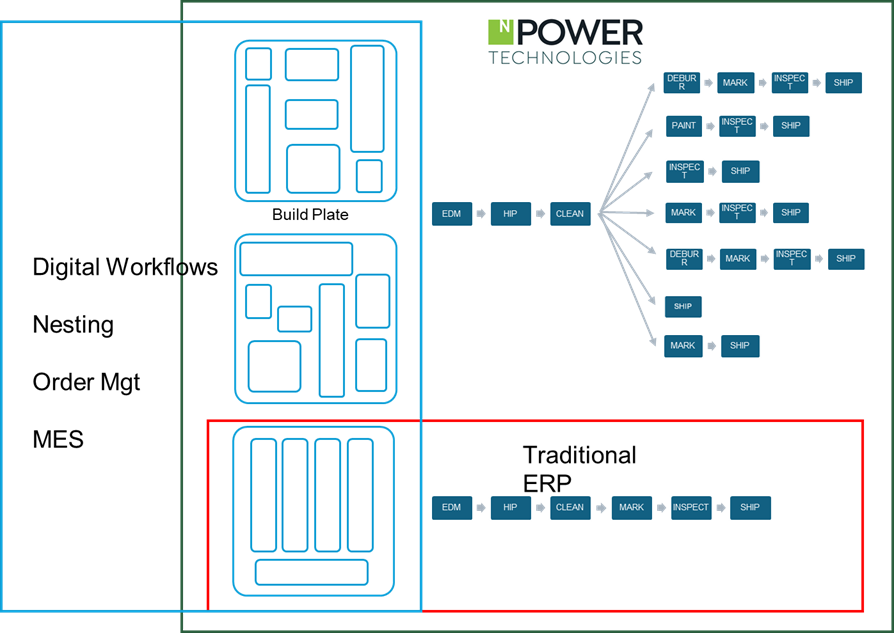

“Every traditional manufacturer who has an ERP has scheduling software and that scheduling software automatically manages the resources on the entire shop floor. The fact is traditional production software doesn’t address the 3D printer’s requirements. Traditional ERP scheduling software can schedule the entire post processing shop floor. They can even schedule the build plate so long as all the parts on the build plate are homogenous and have the same post-processing routing. But what traditional ERP is unable to do is schedule the divergent manufacturing, which is typical in additive, where a build plate containing heterogeneous parts diverges into multiple, independent post-processing routings. Traditional ERP accounts for material availability that is on site and does not address material availability at each individual printer when determining if there is enough material to print a job at any given time.” David Bennett, CPO and Co-Founder at nPower Technologies told 3D ADEPT Media.

For the record, nPower Technologies is one of the tech startups that popped up on our radar last year. The company is a spin-off of ProfitKey International, now part of ECI Software Solutions, a provider of software and services whose aim is to help SMEs in their manufacturing operations.

Kevin O’Keefe, CEO and Co-Founder, and David Bennett took 50 minutes out of their busy schedule to discuss “inefficient cost scheduling in AM” with 3D ADEPT Media. And the first thing we learned is that all the people from nPower essentially have an ERP and manufacturing background. Aware of all the challenges production scheduling can bring to the manufacturing floor, they realized that a specific “automated production scheduling” will be the best fit for AM.

To understand why, we need to figure out the production scheduling challenges that may be specific to AM operations.

When nesting and scheduling intertwine

While the scheduling problem is one of the most investigated in operational research, AM brings additional challenges that have not received much attention. In practice, scheduling consists of grouping jobs into batches and “scheduling” (pun intended) those batches over the available 3D printers.

Nesting, on the other hand, consists of packing multiple parts into a constrained build area or volume, which corresponds to a batch for each production cycle. Decisions regarding the location and orientation of the parts within the build may lead to more complexity in AM scheduling operations.

“That’s anyway what people are referring to when they talk about nesting”, Bennett said.

That’s the reason why “nesting and scheduling are two issues that are intertwined,” he continued. “These nested build plates then need to be scheduled with several factors in mind. One, the build plate must be scheduled so all parts on the plate can be delivered on time to the customer. Two, each build plate must be scheduled on an additive manufacturing machine that is available (open capacity) and capable (technical and qualification requirements). When people talk about nesting they are referring to optimization and scheduling of parts on the build plate. Nesting addresses scheduling parts only on the 3D printer. Production scheduling schedules all the resources on the shop floor, not only the 3D printer but all the other work centers (deburr milling, inspection, etc.) required to produce the finished parts by the date promised to the customer. Nesting and production scheduling are supportive of each other in the additive manufacturing process. One does not replace the other.”

Indeed, in AM, nesting techniques used in process planning often incorporate scheduling concerns from production planning. For example, during the nesting process, emergency parts with close due dates may be grouped into the same build, impacting scheduling decisions.

Indeed, in AM, nesting techniques used in process planning often incorporate scheduling concerns from production planning. For example, during the nesting process, emergency parts with close due dates may be grouped into the same build, impacting scheduling decisions.

“A first look at traditional ERP systems reveals that traditional ERP will schedule the entire shop floor, including the build plate. If the build plate has only a single part on it, it’s easy. Challenges come into play when you must schedule multiple parts on the build plate as well as its post-processing operations,” Bennett explains before going further.

“In reality, scheduling means taking an order and scheduling all the resources required to fulfil that work order on the date it’s required. This can be challenging because, with 100 orders, you must organize all shop floor resources to ensure each order is completed by the customer’s required deadline.”

Simply put, this means there is nesting for AM, scheduling for AM, and nesting and scheduling for AM.

Are these challenges profound when achieving low production volumes or mass production volumes?

At first glance, logic would indicate that the more parts we have in production, the more complex it is to schedule production around them. For Bennett, “it’s a question of mix.”

“The volume is not as critical as the mix”, O’Keefe points out. This means, it’s all about the ratio number of different parts vs and the number of post-processing operations involved in building that those part parts.

“The number of different parts you are going to schedule is more critical than the actual volume itself. Furthermore, complexity arises when the number of operations in the manufacturing chain increases. So, if you’ve got many different parts to build, and the parts that you have require multiple operations, that’s really where production scheduling has the highest value,” the CEO states.

“The nesting challenge may or may not be more complicated with higher complexity parts. However, production scheduling is very difficult because of the challenge of scheduling all released work orders in such a way as to delivery all the parts on time to the customer. Production scheduling challenges are more prominent with higher product mix and greater post-processing operations. The higher the mix on the build plate and the higher the volume of post-processing operations in the manufacturing process, the greater is the scheduling challenge in a very exponentially difficult way”, The CPO completes.

“The nesting challenge may or may not be more complicated with higher complexity parts. However, production scheduling is very difficult because of the challenge of scheduling all released work orders in such a way as to delivery all the parts on time to the customer. Production scheduling challenges are more prominent with higher product mix and greater post-processing operations. The higher the mix on the build plate and the higher the volume of post-processing operations in the manufacturing process, the greater is the scheduling challenge in a very exponentially difficult way”, The CPO completes.

The importance of automated production scheduling

Managing workflows is not a new topic in AM but its complexity might increase depending on the operations you want to achieve. One thing is certain, whether you’re a 3D printing service bureau or an AM user, you will have to manage requests, plan and schedule production, as well as track and manage delivery timelines.

Managing workflows is not a new topic in AM but its complexity might increase depending on the operations you want to achieve. One thing is certain, whether you’re a 3D printing service bureau or an AM user, you will have to manage requests, plan and schedule production, as well as track and manage delivery timelines.

While multiple software solutions can handle these issues, one should keep in mind that different software tools can result in manual re-entering of data – making it fastidious for the operator.

Therefore, I can’t help but agree with O’Keefe and Bennett who believe that inefficient production scheduling might triple the original cost.

That’s the reason why an automated production scheduling solution that will help streamline all the steps from order placement to post-production checks and deliveries seems ideal.

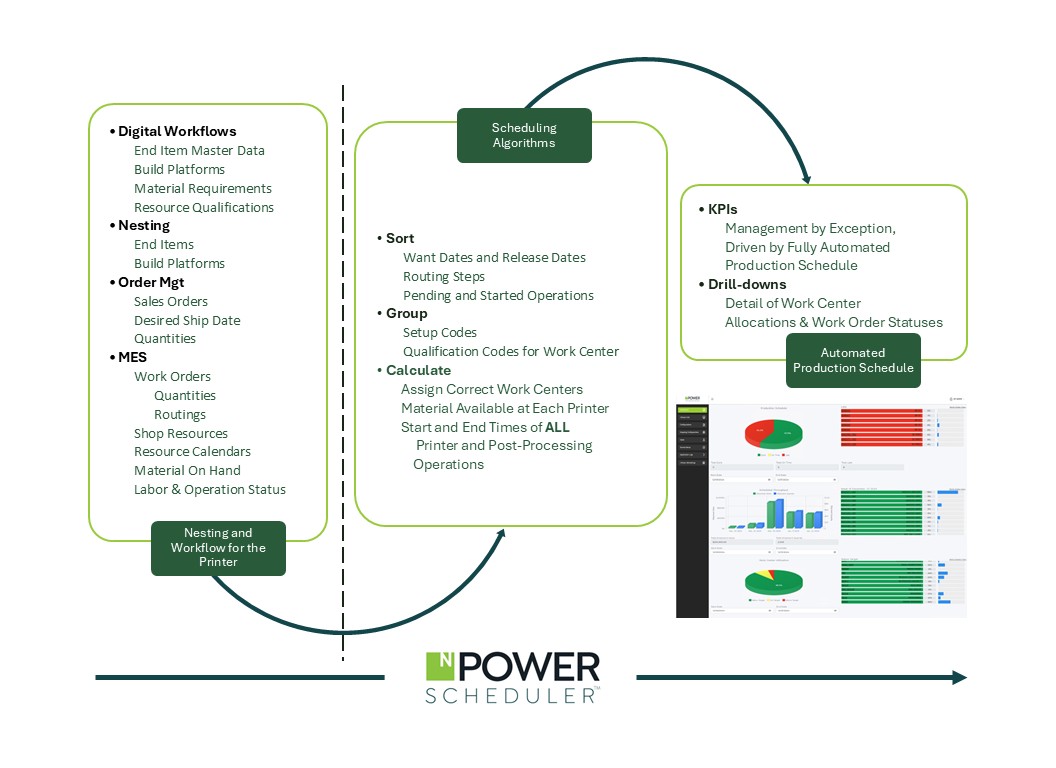

I have heard and seen various solutions in the market and the nPower Scheduler™ from nPower Technologies is one that’s worth the exploration. The ERP-agnostic solution uses MES data from the client’s ERP system to schedule the entire shop floor from the nested 3D printer build plate through all post-print operations.

From the virtual tour Bennett offered me, nPower Scheduler™ provides a rich, graphical interface and seamless integration with existing ERP systems, enabling users to visualize and manage jobs on the shop floor.

“The nPower Scheduler™ is the first, true production scheduling solution for the entire additive manufacturing process, from build plate through post-processing to shipment. Its KPI dashboard provides schedulers/expediters the key data they need to manage by exception the shop floor. This scheduler is unique in that is the only scheduler capable of scheduling a divergent additive manufacturing process, where parts on a build plate branch out into independent post-print processing operations. Crucial to the quality of parts, it schedules build plates based on material availability at each print and on each machine’s capability to produce all the parts on them. Characteristic of the additive world is the need to produce parts only on qualified machines. Uniquely, our solution auto selects machines based on qualification as well as availability (load v. capacity). As setups and changeovers on work centers are non-value add to the production process, the nPower Scheduler can also group operations with like setups to reduce the overall changeover times and increase throughput through the work center,” O’Keefe said.

Interestingly, the company does not position itself as a competitor to well-established nesting software solution providers like Materialise, Oqton and Authentise, but rather as a complementary solution provider.

“Our goal is not to replace any of these products, but help manufacturers understand that in addition to those products, they need a production scheduler to automatically schedule all the resources on the shop floor,” O’Keefe clarifies.

The good news is, for those who rely on spreadsheets because they don’t have enough budget to license a software solution that could address these issues, nPower Technologies’ solution is available through a subscription-pricing model.

While we will continue exploring various solutions in the market, it’s evident that ERP systems remain discrete tools with untapped opportunities for solution providers.

This article was initially published in the January/February edition of 3D ADEPT Mag.