Bentley Motors, one of the most sought-after luxury car brand in the world, invests £3 million to double its Additive Manufacturing (AM) capacity at its headquarters in Crewe, England where all Bentley models are built.

While the car manufacturer rarely communicates about its AM activities, this investment confirms that it is a real advocate of AM technologies. The contrary would have been surprising given the fact AM best serves the needs of luxurious cars. As a matter of fact, 2021 alone saw the production of over 15 000 3D printed components at Bentley’s headquarters, a number that will definitely double given the car manufacturer’s ambition to utilise advanced technology to create 3D printed vehicle components and even greater personalisation in customer cars.

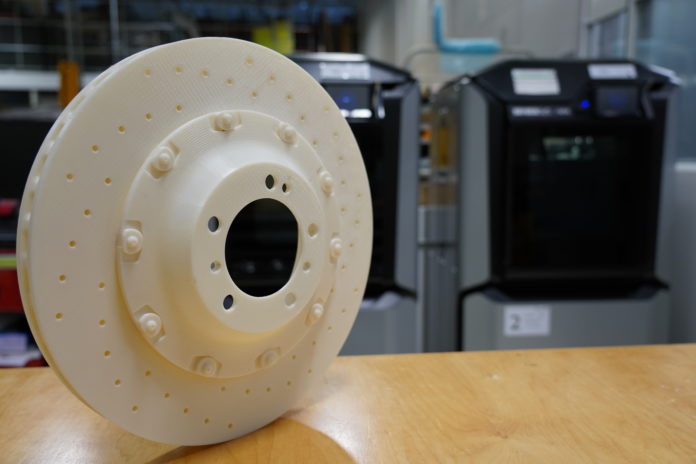

So far, Bentley has used AM for the production of protoypes such full-scale powertrain models and aerodynamic wind tunnel models. End-use parts have also been used for the record-breaking Bentley models that were driven in the demanding Pikes Peak Challenge in America. Furthermore, recently the company accelerates product development by producing a great number of parts without the need to outsource them.

Each of these actions involving AM is driven by Bentley’s Beyond100 strategy, targeting sustainable mobility.

The state-of-the-art AM equipment installed enables a 50 per cent cost saving on parts and by operating around the clock, the facility is capable of producing thousands of components in over 25 different material options. Bentley colleagues from across the company are now being offered training in AM to understand how they can benefit from using the state-of-the-art process in their work.

“Bentley’s approach to additive manufacturing is industry-leading and the facility is quickly becoming a cornerstone of our ‘Dream Factory’ ambitions. One of the key benefits is that it is efficiency led, cutting down on the cost and complexity of a myriad of jobs. This latest investment is also making a significant impact with our colleagues from across the company, helping to create advanced assisted tools to drive continuous improvement throughout manufacturing processes. As we look to the future, there really is huge potential to where this advanced technology can progress, including having a greater ability to personalise parts for our customers and further enhancing the individualisation programme offered on every car”, Peter Bosch, Bentley’s Member of the Board for Manufacturing states.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com