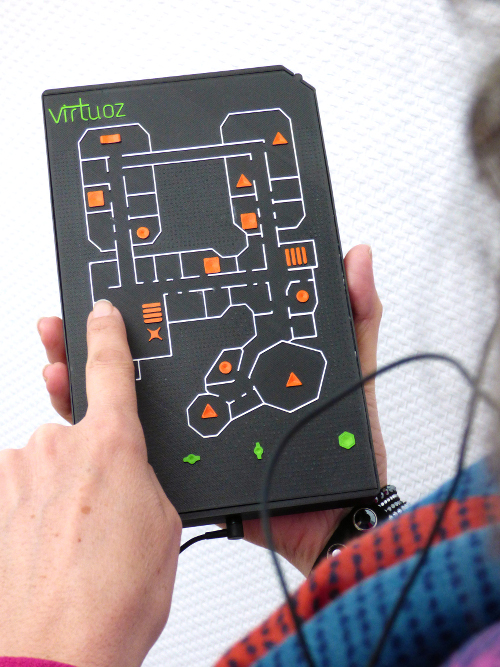

Founded in 2015, Feelobject is one of those start-ups that has a real social impact. The company has designed Virtuoz, an interactive touch screen map that allows visually impaired people to move within buildings. As per the words of Sylvain Huin, Feelobject’s CEO, this map enables visually impaired or blind people to easily find their way in museums, hotels, transport, health or educational institutions.

We discovered FeelObject while carrying out a research on companies that produce daily objects using additive manufacturing. We discovered through their website a company that is willing to invest extra miles in a human project.

Curious to know how they take advantage of additive manufacturing, we invited Sylvain Huin to this Opinion of the Week.

What brought you to additive manufacturing?

During my experience in a consulting firm, I carried out a mission at Airbus where I discovered additive manufacturing and its potential. I discovered functional end-parts. My background in production and supply chain has eased my understanding of this technology. Thereafter, I spent a year studying the different types of AM technologies and together, with two other partners, we launched FeelObject, and decided to specialize in composite AM.

How do you use additive manufacturing today? How does your product work?

At the beginning, we worked on R&D projects but also for major accounts. We have decided to work on a valuable product that would match our company’s values.

Visually impaired and blind people encounter a number of challenges in their daily movements. To help them overcome these challenges, we collaborated with a research laboratory to create Virtuoz, a fully customizable map that integrates audio information which would facilitate their understanding of their environment.

Regular trials with users enable us to improve the patent-pending solution. Electronic components are embedded in a 3D printed box that features a building map (walls, markers, etc.).

Additive manufacturing enables us to produce an accurate and smooth surface, which is crucial for the touch-screen solution. Indeed, users can only read the map using their fingers in order to have a clear mental representation of their environment.

Your tool allows visually impaired people to move around in buildings. Why only in buildings?

Buildings because that was the first issue we identified and to which no solution was found. Still today, it is the only solution that gives a certain autonomy in an unknown environment.

We are currently studying the potential of Virtuoz in outdoor environments. The urban space is complex, we need to identify solutions that might improve Virtuoz and enable its use in outdoor spaces.

What type of initiatives would enable you to develop your product? (Activities, specific partnerships?)

Virtuoz is the first of its kind that gives a certain freedom to its users.

We welcome all initiatives to promote Virtuoz to both end-users and businesses (companies, tourist attractions, hotels, administrations, health and education establishments).

Our challenge for 2019 is to evaluate how much our solution can improve users’ life, to identify other improvements, thus to expand the number of people whose mobility can be improved.

How do you perceive the use of 3D printing in the manufacturing of daily objects? Do you think this technology has a long future?

I strongly believe additive manufacturing will last a very long time and that applications will proliferate in our daily lives. The evolution over the past 5 years has been considerable both in terms of 3D printers and materials, not to mention new design approaches, but this is nothing compared to what awaits us. I look forward to seeing how far our imagination will go.

Any last words?

In order to study the use of Virtuoz in outdoor environments, we have launched a crowdfunding campaign on Ulule open until May 6th, so if you want to change the lives of visually impaired and blind people, feel free to support us.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js (adsbygoogle = window.adsbygoogle || []).push({});