UpNano GmbH, a developer of 2-photon polymerization (2PP) 3D printers, joins forces with Glassomer GmbH to develop a manufacturing process for 3D-printed fused quartz objects.

Glassomer that you may have recently discovered in a partnership with Lithoz, has built up expertise in glass 3D printing. This joint development aims to achieve high-precision shaped parts in the mm and cm range.

Glassomer GmbH’s solution has been modified for two-photon polymerization (2PP) 3D printing using UpNano’s NanoOne high-resolution printing system.

The challenge in manufacturing complex 3D objects and the three-step process

Manufacturing minuscule and complex 3D objects in glass is a challenging process. This is even more the case, if the required material is to be high-quality fused silica (SiO₂) glass, which has an exceptionally high melting point. The only possible methods that can be used are based on non-commercially available equipment and include melting glass fibers using laser beams or fused deposition modeling to produce soda lime glass. These methods often result in final products with rough surfaces that are undesirable, UpNano explains.

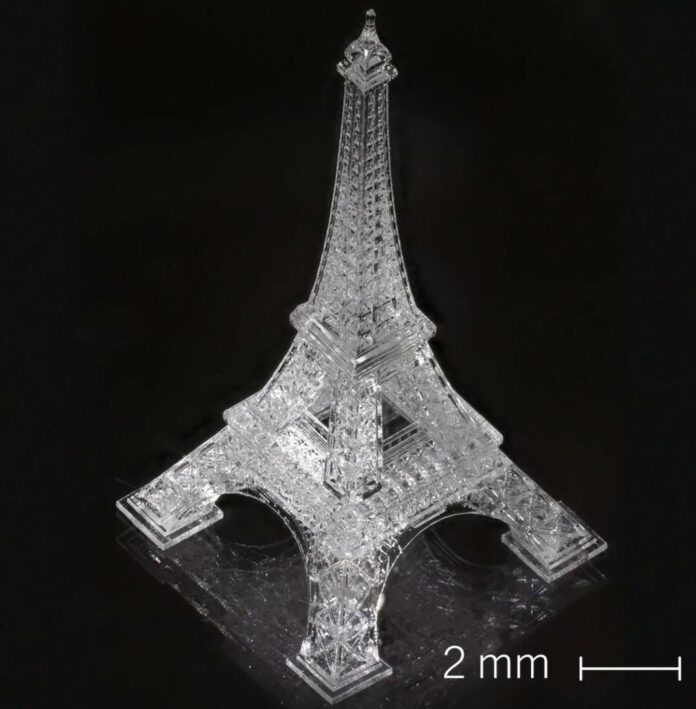

To produce smooth fused silica parts in the mm and cm range with features in the μm range – using 3D printing, the teams relied on a three-step process.

Markus Lunzer, team lead of Materials & Application at UpNano explains: “The first step is to design and print the desired structure using all the advantages 2PP 3D-printing offers. The second step is to remove organic binder material followed by a high-temperature sintering process, the third step.”

At the core of this is a newly developed nanocomposite “UpQuartz”. In addition to SiO2 nanoparticles, it contains a specially designed polymer matrix that allows the composite to be 2PP 3D-printed in the first place. The printing process produces a “green part” that already has the shape of the final and desired structure. To obtain the fused silica product in the end, the polymer matrix must be removed. Heating the green part to 600°C effectively removes the polymer matrix, leaving behind the “brown part”. This is all SiO2 nanoparticles in the shape of the final product. The structure is sintered and fused after exposure to 1,300°C. During the post-processing, the object undergoes isotropic shrinkage of approximately 30%. This can easily be compensated for by an appropriate upscale of the green part using UpNano’s software.

“This innovative production process we developed”, says Markus Lunzer, “is ideally suited for larger 3D-printed glass parts that require high-resolution and high-precision, in the fields of engineering, and chemical, medical or research applications.”

Fused silica offers superior optical properties, along with biocompatibility as well as high chemical inertness and exceptional heat resistance, making it an ideal material for a vast range of applications.

The production of fused silica objects by 2PP 3D printing was a joint development between UpNano and Glassomer. The German company has previously enabled the production of fused silica objects by employing technologies such as soft lithography, injection molding, as well as conventional 3D-printing. Now, the joint material development from UpNano and Glassomer also allows the use of high-precision 2PP 3D-printing to produce fused silica objects.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com