On March 8th, 2022, Laxxon (short for Laxxon Medical), a pharma-technology company appeared on our radar when Evonik Venture Capital, the venture capital business of specialty chemicals company Evonik, announced an investment that expanded their activities on the healthcare 3D printing market. Laxxon was founded in 2017 by Helmut Kerschbaumer, Dr. Achim Schneeberger and Klaus Kühne, who bring to the table over 20 years in the pharmaceutical industry.

The company’s activities lie in the development of a 3D screen printing technology that seems to drastically change the manufacture of drugs in the pharmaceutical industry. The truth is, other companies have been, and are exploring the use of 3D printing for the manufacture of drugs but Laxxon’s process is intriguing as it requires paste as starting material. Furthermore, there are very few companies that develop and commercialize 3D printing technologies for the pharmaceutical industry, but their applications are yet to be commercialized. Laxxon brings a fresh air to this market, as it can already demonstrate how it is effectively improving some treatments in the healthcare industry.

So, what is this 3D screen printing technology?

“We were excited by 3D screen printing once we learned the breadth of its pharmaceutical applications. In particular, the almost unlimited possibilities with influencing the release profiles in a drug delivery system. This is what motivated us to start Laxxon”, Klaus Kühne, COO, told 3D ADEPT Media.

Laxxon’s 3D screen-printing process is based on SPID® (Screen Printed Innovative Drug) Technology, a hybrid process between traditional 3D printing and screen printing.

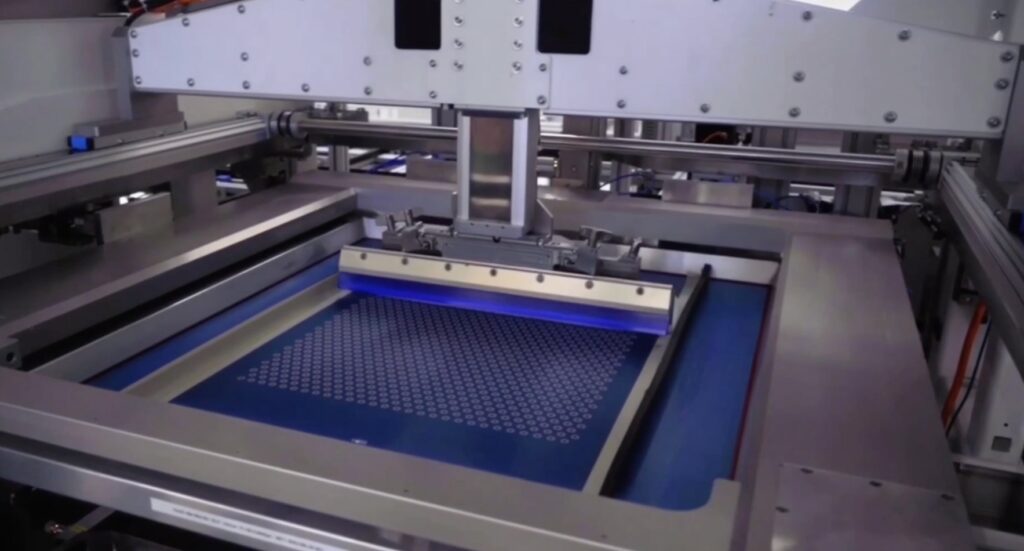

“Unlike 3D printing, our technology does not rely on lasers nor a heated nozzle to administer printed products. This is important because when working with active pharmaceutical ingredients (APIs), the application of heat drastically limits the ingredients which can be used. With our technology – similarly to a traditional screen printing process used in the aerospace industry/electronic industry etc. – we apply a thin layer (as fine as 10 microns) of our printing paste onto a printing tray, which then oscillates between the printing station and the drying station until the batch of tablets is complete. Through varying screens and the composition of the printing pastes, tablets – or any drug delivery system produced with our technology – we can print complex geometric structures layer by layer, allowing for the heterogeneous distribution of APIs and controlled release once administered to a patient. Compared to traditional tablet manufacturing, which consists of pressing a homogeneous API solution, our technology is playing a game of chess while traditional approaches are playing checkers.

What is also unique and advantageous about SPID®-Technology is its ability to handle small batch sizes for pre-clinical/clinical trials in addition to industrial-scale mass production. Currently, our technology can produce up to 560 million units per year.

In terms of materials, our printers can process almost all APIs with no limitations. Our team of chemists at our R&D site in Jena, Germany works to develop our pastes per product in our pipeline”, Kühne explains.

The 3D screen-printing technology draws attention in a context where 3D printing technologies are increasingly used in drug delivery systems due to its potential advantages over customizing drugs in individually adjusted doses. On another note, the technology also raises concerns regarding its ability to manufacture more complex oral dosage forms in the setting of mass production with high reproducibility.

“Laxxon’s technology works to reduce the daily intake of a tablet, thus allowing for multiple dosages within one pill. This differs from the polypill concept – personalized medication based on a patient’s genetics and prescriptions.

Laxxon does deal with multiple APIs in a single tablet, but only APIs which are classically paired, such as Levodopa and Carbidopa, or an active API and a buffer”, Kühne adds without emphasizing whether they can achieve mass production with high reproducibility.

To provide a tangible example of how they play their part in the pharmaceutical industry, the company recently explained how their technology presents opportunities to improve Levadopa, a treatment used against Parkinson:

“One severe effect of Parkinson is the ‘freezing of gait’ effect where patients are not able to move in the morning until they have their standard Levodopa dose. If patients are not able to move, they need a nurse or relative to administer the intake of Levodopa.

Laxxon has been developing a ‘new product generation’ of Levodopa with a delayed release program of 8-9 hours. This means the patient can, for example, take our Levodopa tablet in the evening and it will be released automatically after 8 to 9 hours to prevent the freezing of gait effect. This will be a dramatic improvement for the Parkinson’s patients suffering from freezing of gait”.

The business model behind Laxxon’ SPID® and what’s next in the pipeline

Laxxon’s business model is twofold. The company outlicenses their technology to pharmaceutical companies looking to develop new drugs or optimize their current drugs. They also offer these pharma companies R&D, their technology, and a final product that can then be manufactured. This does not take into account the fact that they have their own in-house product development pipeline for generic drugs.

Lastly, ever since Evonik invested in Laxxon, both teams have been working on multiple product development projects. A delayed release profile DDS concept is currently one of their key areas of interest.

“This delayed release profile allows for multiple dosages of medication to exist within one tablet. For some patients and medications, this would lessen the number of pills and the number of times a day required of a patient. For others – such as Levodopa/Carbidopa, the leading Parkinson’s Disease medication – our delayed release profile means autonomy for patients who no longer would require a caretaker to administer medication due to the medicine’s short half-life”, Kühne concludes.

This article was first published in the March/April edition of 3D ADEPT Mag.