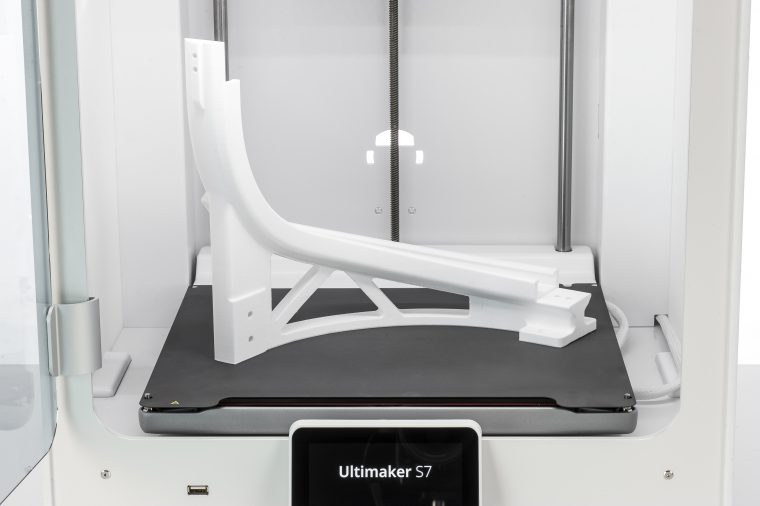

UltiMaker, the company that combines Ultimaker and MakerBot’s products under one roof, has launched the UltiMaker® S7 – in the series of ‘S’ 3D printers.

“Over 25,000 customers innovate with the UltiMaker S5 every day, making the award-winning machine one of the market’s most used professional 3D printers,” says UltiMaker CEO Nadav Goshen. “With the S7, we took everything our customers loved about the S5 and made it even better.”

The UltiMaker S7 introduces a range of new features designed for ease of use and print reliability. A new flexible build plate makes removing prints a breeze and the integrated Air Manager filters out up to 95% of UFPs and improves temperature regulation. The S7 also features improved automated bed leveling for reliable first-layer adhesion.

Material partners such as igus and Polymaker who have already tested the system for in-house applications testify to this improved bed levelling system that enables to print precise parts and better adhesion to the new flexplate.

Advances in temperature regulation on the S7 allow users to capitalize on the large 330 x 240 x 300 mm build volume – with reliable accuracy from the first printed layer to the last. The flexplate also provides easy part removal post printing, reducing labor so users can get on with other tasks.

The S7 will be compatible with the UltiMaker ecosystem of over 200 materials and offers seamless integration with software UltiMaker Cura, easy printing with the widest range of materials on the market, and support dedicated to customer success.

The S7 will be compatible with the UltiMaker ecosystem of over 200 materials and offers seamless integration with software UltiMaker Cura, easy printing with the widest range of materials on the market, and support dedicated to customer success.

“With the S7 Pro Bundle, users can also pair the S7 with the UltiMaker Material Station to print with up to six spools with automatic material switching and humidity control. The UltiMaker S7 is a fantastic addition to our S-Series of printers,” says Goshen, concluding, “As more customers are using 3D printing to grow and innovate their business, our goal is to provide them with a complete solution to be successful. With the new S7, customers can be setup and running in minutes: managing printers, users, and designs with our Digital Factory software, improving their 3D printing knowledge with e-learning courses on the UltiMaker Academy, and choosing from hundreds of materials and plugins using the UltiMaker Cura Marketplace.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com