The University of Florida has received the BOD3, a 3D construction printer, a 3rd-generation model manufactured by COBOD International in Denmark.

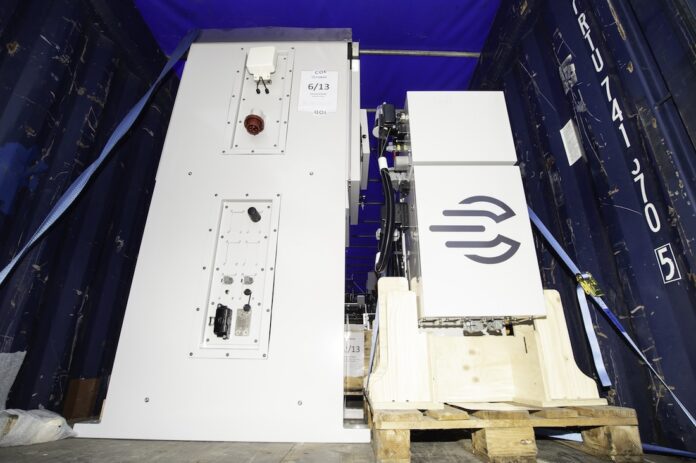

The 27,000-pound two-story printer is kept in “The Pit” (Weil Hall Structures & Materials Lab) at Herbert Wertheim College of Engineering. It primarily consists of 3 major elements like mixer/cement silo, concrete piston pump & 3D printer components.

Iris V. Rivero, the UF Department of Industrial and Systems Engineering professor explains, “The opportunities for the interplay of artificial intelligence, machine learning, data analytics & smart manufacturing will be one of a kind in the country. With UF’s access to the Space Coast, vast areas of shoreline, and infrastructure needs, we will be the hub of innovation in Industrial Manufacturing & Construction Engineering. UF Industrial & Systems Engineering department will lead the path defining one-of-a-kind, infrastructure-driven interdisciplinary research and education.”

The BOD3 printer will be included in the curriculum of various engineering courses such as construction, manufacturing, data analytics, coastal resilience, operations research, structural health monitoring, safety, and design.

The assistant professor of AI from the UF School of Construction Management, Chaofeng Wang reveals, “The development of DCP 3D printing course is supported by a successful NSF proposal with a focus on construction — the first of its kind at a university — demonstrating a forward-thinking approach to incorporating advanced construction technologies into the curriculum. We are collaborating with the College of Engineering to expand this course, reaching more students interested in these innovations. The acquisition of this new 3D printer will bridge the gap between classroom learning and real-world industry experience, while also driving research in additive manufacturing, material science, and construction automation.”

Meanwhile, the latest & relatively unique concept of 3D printing in construction is gaining traction in the United States region. The machines print materials by layering different sets of wet concrete rows with a nozzle modified by an overhead robotic arm to build walls.

Proponents contend that 3D construction printing grows quicker than traditional construction processes by creating comparatively lowered material wastage at cost-effective rates.

Some firms report homes created within a few weeks with a minimal workforce for various machinery operations. COBOD reported the firm called ’14Trees’ tends to build 10 houses in 10 weeks using its BOD2 version in Kilifi, Kenya between (Oct 2022 – Jan 2023).

UF’s printer is one of the renowned Presidential Strategic Initiatives offering $2.5 million over 2 years to enhance the potential of digital design, Artificial Intelligence (AI) & robotic automation for improved productivity, safety & quality in residential & commercial construction sectors. Also, Autodesk funded $1.5 million in grants, a well-known software firm for design, construction & engineering.

“We have a customer at a large Air Force base in Florida. In addition, our customer, 1Print (in Broward County) incorporates our technology to 3D print various structures, including coastal barriers. We collaborate with many universities for research grants, including NSF, printer deployment, lectures & building programs,” says Philip Lund-Nielsen, co-founder and head of Americas for BOD International.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.