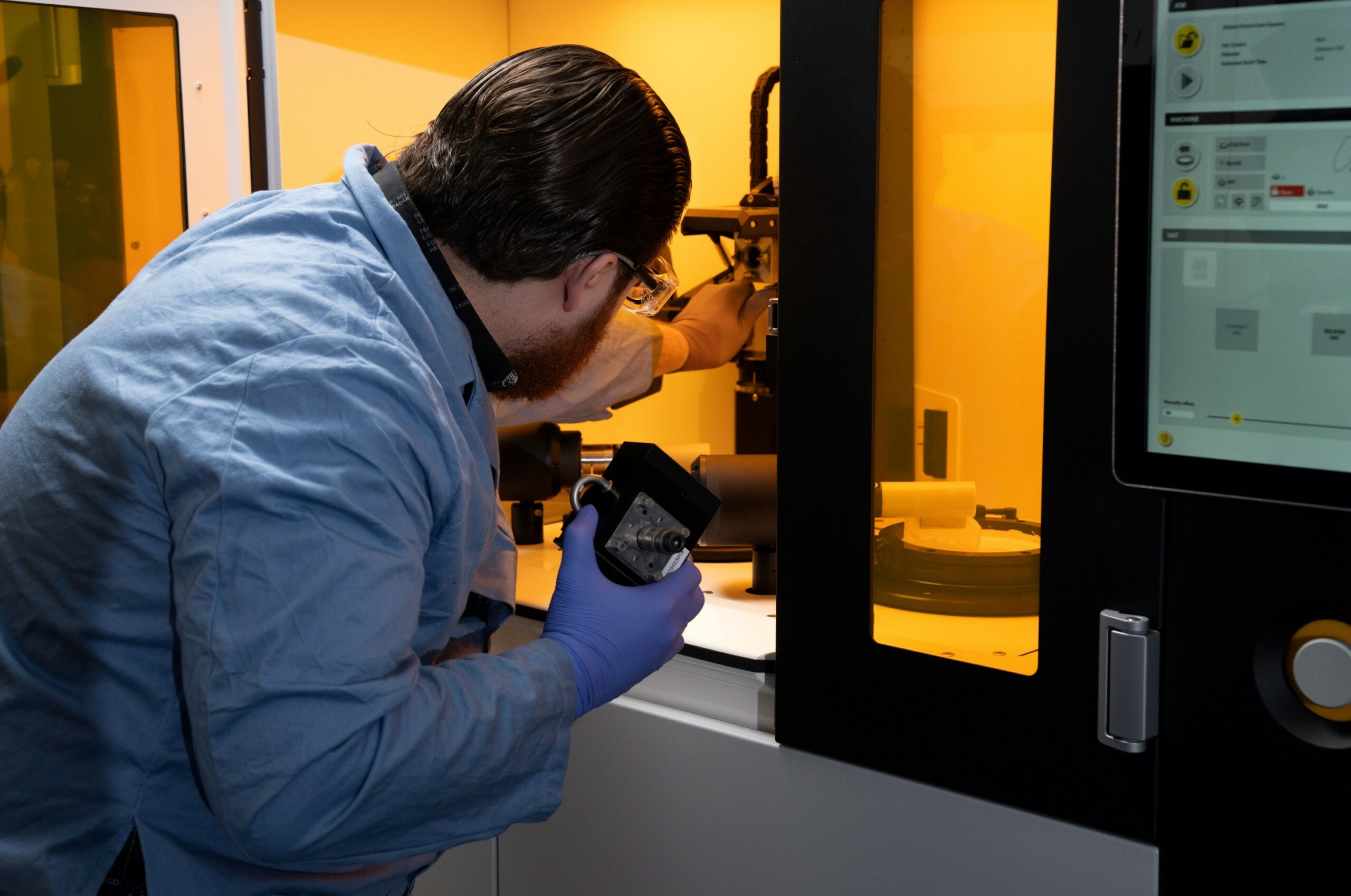

Lithoz, an expert in AM for high-performance ceramics, announced the installation of the first-ever CeraFab Multi 3D printer in the USA, at Embry-Riddle Aeronautical University’s Daytona Beach Campus.

Unveiled in 2023, the Lithoz CeraFab Multi 2M30 made a real splash thanks to its ability to enable multi-material 3D printing through the combination of ceramics and metals, as well as ceramics and ceramics in complex geometries.

Thanks to its open platform, the 3D printer provides the opportunity to develop new composite materials, while exploring multi-functional applications with no restriction in grading.

The research team at Embry-Riddle will be the first one to explore the capabilities of this 3D printer for projects such as the development of wear-resistant coatings for lunar exploration systems and functional sensors that could support in-situ resource utilization.

Dr. Seetha Raghavan, Professor of Aerospace Engineering at Embry-Riddle, emphasized the transformative impact of this Lithoz machine: “The Lithoz CeraFab Multi 2M30 enables our researchers to manufacture ceramics with intricate geometric features across scales with remarkable precision. Its capability to print combinations of ceramics tailored for specific needs is pivotal in accelerating material design.”

Before this installation in-house, the 3D printer has already supported campus projects, such as aiding the C.R.A.T.E.R. team during NASA’s Human Lander Challenge. Using the Lithoz machine, the team successfully developed bio-inspired ceramic patterns to mitigate dust adhesion on lunar surfaces. These precision-engineered patterns, modeled after hydrophobic surfaces like the lotus leaf, underscore the printer’s unparalleled capabilities, Lithoz said.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com