This “Opinion of the Week” brings us to Poland to discover Omni3D. We have been watching the company for a while and one thing that draws our attention is the fact that, among all its 3D Printing materials, the CF-PA12 with carbon fibre is more highlighted in its use cases than other materials.

The second thing is that the company recently added another string to its bow by launching its first industrial 3D printer, a launch that was done in a very atypical way at the Formnext exhibition.

Curious about their activities and curious to learn more about the Polish market, it was obvious to invite Marek Starow in this Opinion of the Week. As Export Manager at Omni3D, he is responsible for channels development and works in close collaboration with the R&D department. He is therefore the appropriate person to provide accurate information on both the company and this market.

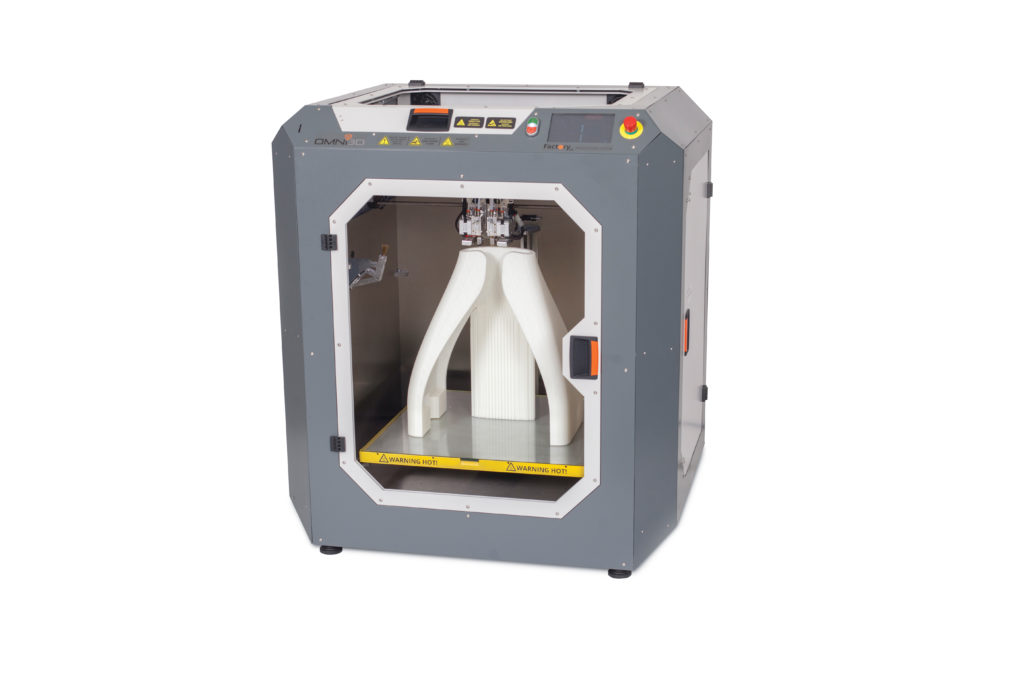

Let’s start by the Factory 2.0 3D Printer. Omni 3D unveiled the 3D printer in a very impressive way at Formnext. How does the 3D printer distinguish itself from others of the same range?

We highly appreciate positive feedback from Formnext as it is a great opportunity to show what is inside a machine rather than showing a simple brochure. First, Factory 2.0 precision is due to drive transmission provided by screws on all axis. We have unveiled a beltless system on all axis, which is quite unusual in the industry.

Thanks to precise mechanics and advanced automatic leveling system plus system of lifting inactive head, it enables great precision on printed parts, very smooth surface plus easy support removal.

This feature allows users to introduce FFF 3D printing to production of low volume parts as well as quick production of strong tooling.

Among the company’s various 3D printing filaments, the CF-PA12 with carbon fibre seems to be the mostly highlighted. Why this emphasis on that material?

In recent years many companies producing material extrusion 3D printers were putting much effort to print Ultem, PEEK and other high-performance thermoplastics.

What increases a client’s interest in a 3D Printer is the ability of the latter to print PEEK family polymers. However, most of the companies needs show that there is no economical reason to use those expensive materials.

That’s the reason why we want to highlight CF-PA-12 as a great alternative in applications where high strength or thermal resistivity is necessary. Carbon fiber polyamide-12 from OMNI3D is 4-6 times cheaper than PEEK, while exceeding some of its properties, for example tensile strength.

What are the different geographical and sectorial markets that Omni 3D targets?

Omni3D is already present on 15 markets mostly in Europe but also Russia, Australia and New Zeland. All markets are different and we see that the Polish market is getting more and more mature. Unfortunately, we are not yet present in Belgium.

A few years ago, a Polish 3D printers’ manufacturer told us that there is a certain support that exists between manufacturers in Poland. Do you agree with him? How do you perceive the Polish 3D printing market?

Many people we met at Formnext noticed, that there is a lot of polish companies that were exhibiting. A few years ago, when MakerBot was only an emerging company in Poland, there were a lot of hobbyists tinkering with RepRap printers in garages.

They connected with each other on internet forums, where they shared their experience. Today, the market shows that those same people created the first companies that produce 3D Printers and filaments in the country. Furthermore, bonds they created within this environment have resulted in good collaborations between their companies.

Today, the polish 3D printing market is much bigger and mature, so room for cooperation is much smaller but I think we all live peacefully.

We are still at the beginning of the year and companies have just defined their strategy. What will be Omni 3D strategy for 2019?

We do not want to reveal too much now but we will be launching a new machine as we showed a prototype at Formnext. We will be releasing Omni 500 LITE – younger brother of our Factory 2.0 machine with less features and no heated chamber – the system will have the same precision than its brother but with less available materials for less demanding customers. A perfect solution for education and small & medium businesses – with great price/performance ratio.

Your last word?

Thank you for letting us share our thoughts on 3D Adept, we hope to see you on the next 3D printing events.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter! Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com