This week at RAPID+TCT, TECDIA Co. Ltd, an expert in precision machining, introduces a 3D printing nozzle named kaikaFIN (kaika1310), engineered for the Mako Hotend from Slice Engineering, a provider of 3D printer upgrades.

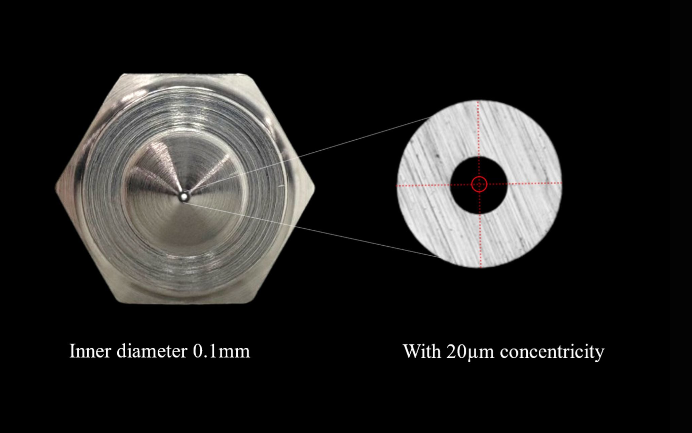

Available in 0.1mm and 0.4mm diameters, the U.S. market will initially offer the 0.1mm version, while both sizes will be available in Japan.

TECDIA builds on its expertise in precision machining to create an internal 30-degree taper, enhancing material flow and preventing clogging. According to the company, its concentricity of 20 microns ensures ultra-smooth layer transitions, delivering good print quality.

The “Mako Hotend” by Slice Engineering is an officially approved upgrade part for the Bambu Lab X1 and P1 series. Unlike stock hotends, it allows independent nozzle replacement, significantly boosting productivity. The introduction of the “kaikaFIN” nozzle fulfills a long-standing demand for 0.1mm printing with Bambu Lab printers. This solution enables professional users and customization enthusiasts to achieve precision and flexibility in their prints.

Looking for a job in the AM industry or hiring new talent? You can post job opportunities on 3D ADEPT Media for free or explore openings via our job board. Stay connected by following us on Facebook, Twitter, LinkedIn & Instagram, and subscribe to our weekly newsletter for the latest updates. Have a story to share or want to be featured in our next digital magazine issue? Send it to editor@3dadept.com !