Material producer TANIOBIS GmbH positions itself as a key provider of solutions for the aerospace industry with the development of niobium-based alloy powders.

Used in AM, these alloys would help meet the rising demand for components that must maintain mechanical integrity when exposed to temperatures above 1000 °C. For the record, conventional nickel-based alloys reach their mechanical stability limit at around 1050 °C.

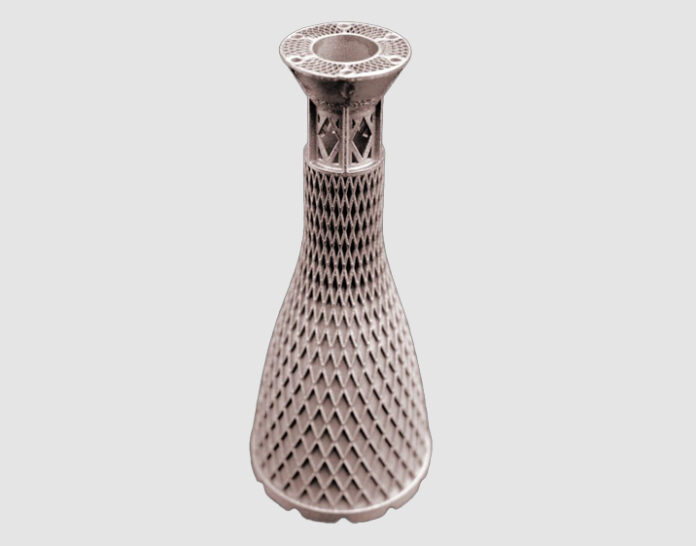

TANIOBIS develops especially the AMtrinsic® C-103 and AMtrinsic® FS-85 niobium-based alloy powders, suited for manufacturing demanding components such as jet engine nozzles, control segments, and satellite thrusters.

AMtrinsic® alloy powders in particular, enable the production of complex, geometry-optimized components which are difficult or even impossible to achieve using conventional methods.

These materials are already in use wherever structural components must perform reliably under extreme temperature conditions.

NASA’s Glenn Research Center in Cleveland additively manufactured different niobium alloys, including C-103, FS-85 and Cb-752, and examined their mechanical strength at elevated temperatures. The results showed that FS-85 and Cb-752 outperform C-103 in respect of mechanical strength as well as creep performance at high temperatures. These results highlight the advantage of these less common niobium alloys and their potential for use in demanding aerospace environments such as thermal protection components or thermally stressed areas of propulsion systems.

“Our AM alloys are specifically engineered to meet such challenging requirements,” affirmed Dr. Bahar Fayyazi, Product Manager at TANIOBIS. “From precise satellite thrusters through to reusable space launch systems, niobium alloys combine high-temperature stability with mechanical integrity, thus offering a material base for new space missions.”

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.