PostProcess Technologies Inc. is currently supporting Splitvision in streamlining their workflow and improving working conditions for post-printing of their Digital Light Processing (DLP) 3D printing.

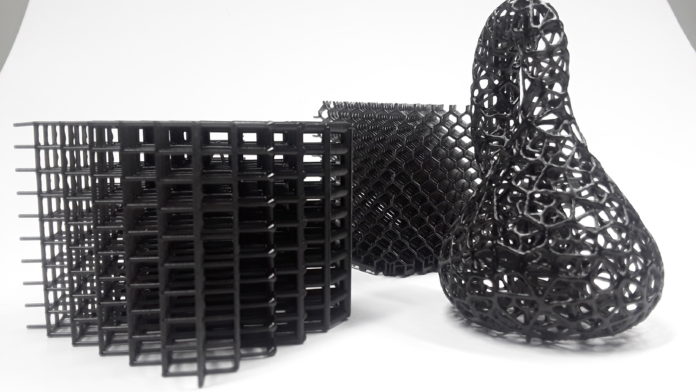

As a reminder, Splitvision produces parts for the medical and automotive industries. Last year, in August, the company acquired 3D Systems Figure 4 3D Printer. Their aim was then to evaluate fitting and assembly before moving into serial production. The new additive process improved their manufacturing workflow but the post-printing stage still raised several issues in terms of time, cleaning of intricate parts, smell and flammability of IPA.

The company’s team therefore turns to PostProcess Technologies’ Resin Removal solution and proprietary detergent specifically developed for that system, to address these issues.

“From the software to the chemistry to the hardware, our focus is on providing a full-stack solution to revolutionize the way that customers post-print for a better additive manufacturing workflow. It is invigorating to see companies like Splitvision benefitting from the use of PostProcess technology,” said Bruno Bourguet, Managing Director, PostProcess Technologies.

A recently published case study outlines the dramatic improvements to their process. Individual parts previously requiring up to 30 minutes each for resin removal are now processed in batches of many parts at once in 4 to 5 minutes with the PostProcess technology.

Speaking of improvements that come with the new post-processing system, Lukass Legzdins, R&D Director at Splitvision, states, “We now can offer printed parts at a reasonable price, especially when we print multiple items in one run. Plus, the nasty bit of the printing process has been eliminated for our staff. After having tried the PostProcess solution, it’s hard to imagine ever going back to using IPA.”

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com