Whirlpool, the American manufacturer of home appliances will collaborate with Spare parts 3D for the production of spare parts. The Home appliance specialist wants to exploit 3D printing to improve its aftersales service.

Spare parts 3D is a Singapore-based company that takes advantage of 3D printing to accelerate industrialization. The start-up offers an online software called “Digipart” that enables its users to determine the most profitable part the can have while using 3D printing. The company explained that they are currently carrying out beta test for features such as the digital inventory repository, the quotation and ordering system. Results shall be made available to all Spare Parts 3D’s customers by end of the year.

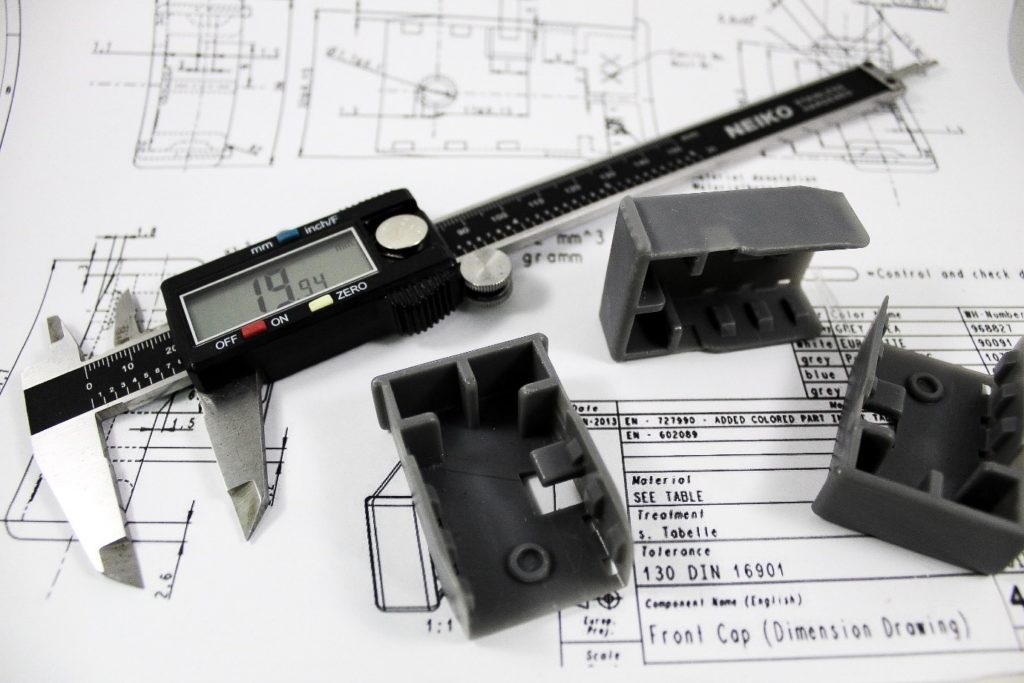

3D printing of spare parts for home appliances

The production of spare parts is gaining momentum in the transport industry as well as in the automotive industry. Such type of production has often been achieved by manufacturers and distributors of home appliances but did not receive a wide adoption at the beginning, especially in France, one of the countries that started offering such type of service in their aftersales service.

As far as Whirlpool is concerned, the manufacturer wants to be a game changer in its field of expertise. The collaboration between the two companies began in November 2017.

Whirlpool wanted Spare Parts 3D to tackle two key issues in a catalog analysis: obsolescence and shortages cases. The Singaporean team therefore reviewed over 11 000 SKU automatically and found out that 7% of the SKU were profitable economically and suitable for a fabrication using additive manufacturing.

Going back on the use of 3D printing for spare parts, the manufacturer will be using three types of processes: HP, FDM, SLA combined with 5 materials (ABS, ABS V0, PA12, Rubber-like resin, and PP-like resins). A first part, a push button made in Nylon with the MFJ technology, is a good start of this offer that has been added to the company’s customer service.

A first part that will certainly bring hope in the use of 3D printing for the home appliances industry. Franco Secchi, Head of Consumer Services and Quality for Whirlpool EMEA commented on this collaboration’s success: “Spare Parts 3D gave me a pragmatic view on how to use 3D printing in our business. I know we won’t make large production batches with this technology, but there is an excellent value to solve obsolescence and shortage issues which generally fold into low volumes demands. This way 3D printing can have a direct significative impact on our customer care.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});