Two years ago, Unitedcoatings Group, a global contract manufacturer for Industrial Gas Turbine, Aviation and Medical Device applications, launched its additive manufacturing division Lincotek Additive, a company that is on a mission to deliver AM services to improve the supply chain.

Since then, we have kept the company on our radar to see how it will built its presence in this already well-furnished industry. Last year, when the company started installing its new equipment, we knew that it would focus on metal AM, a segment where there is a still demand to fulfil.

As part of its development program, Lincotek keeps increasing its production capacity, this time with further EOS M400-4 additive machines that will meet the needs of customers in the aerospace and industrial sectors in Switzerland.

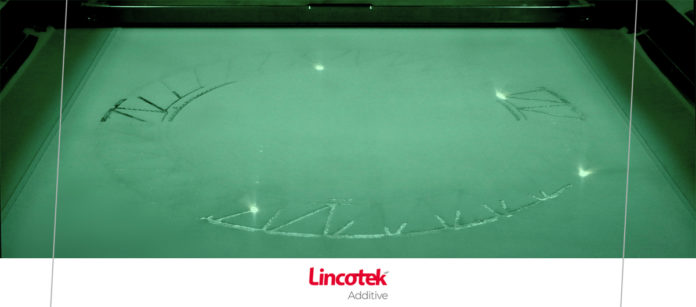

The EOS M400-4 is a Selective Laser Melting (SLM) machine, well recognized in the market for additive production of complex alloys, its large build chamber volume (400 x 400 x 350 mm XYZ) and its higher productivity rate, with 4 x 400W lasers enabling Lincotek to produce also larger IGT or Aviation parts. The Swiss plant is designed to scale up production and development work in AM helping, customers to build or expand their serial production. As a reminder, the center already comprises a high temperature vacuum furnace has been installed, specifically designed for the heat treatment of additively manufactured Ni-base superalloys. A fully equipped metallography lab is available, along with other analytic equipment, such as a fully automated GOM cell, to develop, qualify and produce AM components. The main focus for the facility from a materials point of view is the superalloys used for high temperature applications, such as HASTELLOY® X and IN939. More advanced alloys, including IN738, are currently under development.

Most importantly, the AM services provider has also been granted EN9100:2018 certification for its quality management system, a rigorous process that can only make the team confident in their ability to deliver their customers the best value for their customers.

Located between Zurich and Baden, Lincotek Additive takes advantage of a strong network of experienced suppliers in the area. In addition, the proximity to the French and Italian plants of the Group leads to a very close and efficient collaboration, contributing to best-in-class contract manufacturing services from powder to ready-to-market parts.

Remember, you can post AM job opportunities for free on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com