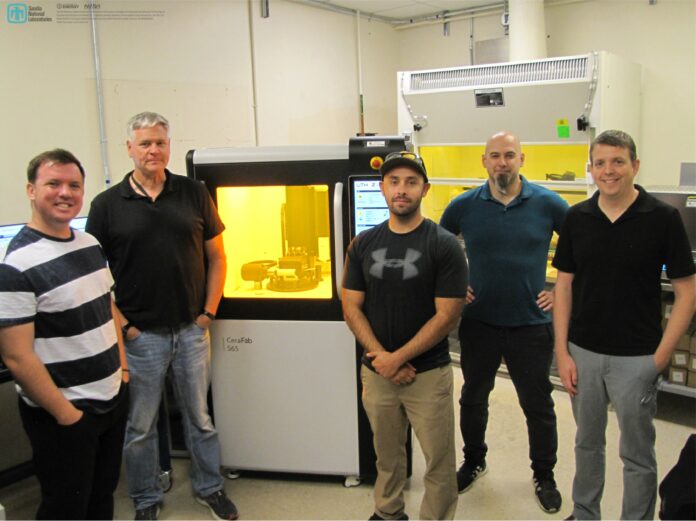

Sandia National Laboratories expanded its research and development capacity with a second Lithoz CeraFab 3D printer. This acquisition represents a step in Sandia’s attempt to create more reasonably priced and efficient advanced ceramic components.

According to Lithoz – the developer of LCM technology, with their first 3D printer, the team at Sandia produces components at a fraction of the cost of conventional techniques. Lithography-based Ceramic Manufacturing (LCM) technology drives the CeraFab S65. This method guarantees strong end pieces and improves design freedom as well. From months to within a week, it drastically lowers product development cycles.

The great degree of automation given by Lithoz’s LCM system helps to attain this efficiency. It streamlines simple design changes and eliminates the need for tools. Sandia may therefore reduce cost and schedule risks by balancing the exact design requirements of end customers with the fast production scale.

The adoption of Lithoz 3D printers and ceramic materials by Sandia seeks to increase the manufacturing of ideal ceramic subcomponents on a scale. The appealing technological benefits of ceramic materials should open new applications for them. Vice President of Lithoz America, Shawn Allan, expressed hope for Sandia’s future success by witnessing the 2nd version of Lithoz 3D printer’s higher capacity.

Author: Nagarjun M. Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.