The fuselage, main body or “trunk” of an aircraft, is a streamlined tube that houses the crew, passengers, and cargo, and serves as the central structure to which wings, tail, and landing gear attach, providing aerodynamic shape, strength, and a pressurized environment for flight.

Until a collaboration between aerospace company Saab and Divergent, this tube had never been manufactured with additive manufacturing. Drawing lessons from its latest fighter, Gripen E, Saab aims to break the cycle of painfully long and expensive upgrades other aircraft undergo whenever upgrading their software or the computer hardware underpinning it.

According to the company, rapid upgradability and flexibility is, perhaps the most, important factor on the battlefield today.

Together with Divergent, Saab is developing a software-defined fuselage. Described as a “world’s first”, the manufacturing process of this fuselage has at its core AI-driven algorithms and additive manufacturing.

“We are asking ourselves the question – In Gripen E customers get a platform where they can code mission-critical applications in the morning and fly them in the afternoon. How can we give them the same level of software flexibility, but for actual hardware? We call this Software-Defined Hardware Manufacturing”, said Axel Bååthe, Head of The Rainforest, Saab’s internal startup for transformative innovation.

How to combine model-based engineering (MBE) methodology with the learnings from Gripen E’s SW-defined avionics system to take aircraft design and manufacturing to the next level?

This one question shapes the development of the fuselage.

“We envision that Saab’s future production factory is our most important product. We want to be able to give our customers freedom. Freedom to not feel locked into a specific design, neither in hardware nor software. The production factory will be one that reconfigures itself instantly to build whatever our joint digital twin looks like, without being limited by expensive investments in new tooling. We sum this up as ‘CAD in The Morning, Fly in The Afternoon’.”

“This factory is of course not built in a day and will require substantial innovation in many different types of manufacturing, together with radical rethinking in everything from how we design aircraft parts to how we maintain aircraft. But we wanted to take the first steps on this journey here and now to show what will be possible. One of these first steps was to look at how we could reimagine how we build primary load-carrying structures in aircraft fuselages in a more Software-Defined way. This is how we came across Divergent Technologies.”

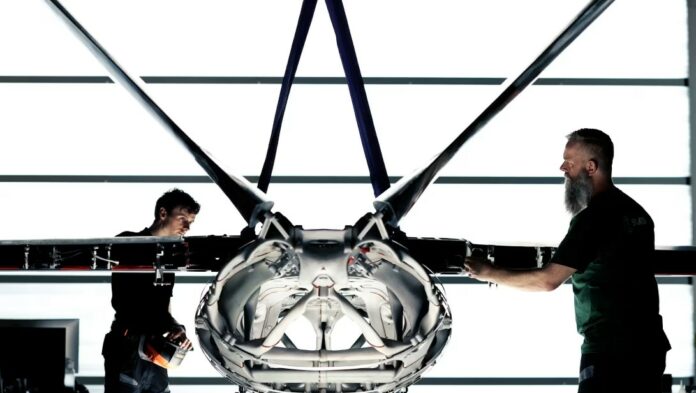

The fuselage was developed and realized with no unique tooling or fixturing, instead utilizing Divergent’s software-defined manufacturing assets that combine industrial-rate laser powder fusion additive manufacturing with universal robotic assembly. The fuselage, at over 5 metres long and comprising of 26 unique printed parts, will be one of the largest additively manufactured metal structures that will have ever undergone powered flight, Saab explains.

According to Bååthe, with additive manufacturing load-bearing structures do not have to follow straight lines and right angles as ribs and stringers, but can rather, organically, follow the optimal load-paths. It is impossible to, as a human, draw these parts, instead they must be generated by optimization and AI-algorithms.

The joint Saab & Divergent design team has been able to reduce the number of parts by at least a factor of 100, replacing traditional riveted machine parts with organic, interwoven structures.

This leads to dramatically lower lead times in assembly. This technology also enables more flexible weight optimization and functional integration within fuselage structures, allowing for the printing of wiring, thermal management systems, and hydraulic and liquid systems directly inside the structure, further improving performance.

“The fuselage has successfully passed its structural proof-loading and is scheduled to fly in 2026,” Bååthe concludes.

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.