Ronawk, an expert in Advanced Tissue Mimetic Technologies, has named B9Creations its Global Additive Manufacturing Partner, after a joint development effort to automate and mass produce Ronawk’s Bio-Blocks®.

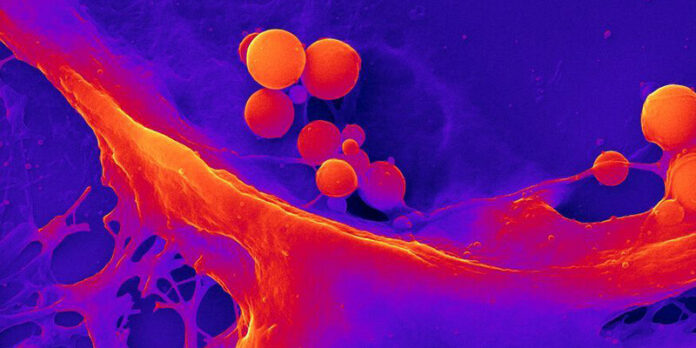

While other methods force cells into an artificial environment, Ronawk’s Bio-Blocks recreate an environment that allows cells to form tissues as they would naturally. The result is tissue which resembles the native architecture and function of tissue in the body. This key advantage is why Bio-Block cells maintain a high-level of metabolism, viability, and proliferation which leads to superior output in both quantity and quality of the production of a variety of biologics to drive advancements in human and animal biological therapies, diagnostics, prognostics, and countermeasures to biological threats.

Since the 1950s plasticware has been the most common platform scientists use to grow cells. These vessels are 100,000X stiffer than soft tissue environments like skin, liver, fat, kidney, lungs and the brain, and can only grow in 2D unlike the 3D environment of the body. Since the 1980s, scientists have been able to grow 3D organoid structures utilizing gel-based scaffolds. These scaffolds have a host of issues including being made from animal tumors, inconsistent results that are not repeatable, and are incredibly difficult to scale.

Ronawk’s tissue mimetic substrate enables cells to cultivate microenvironments that streamline the process of growing tissue and cells outside the body in a manner that more closely resembles how cells grow naturally in the body:

- Enables the flexible introduction of various stimuli.

- Supports co-culturing of multiple cell types.

- Allows for cell isolation and subsequent in-depth cellular signaling analysis.

- Creates an ideal environment for studying cellular functions in real-time.

- The form factor of Bio-Blocks allows for imaging to take place throughout the process.

Ronawk’s platform enables researchers to explore unseen intricacies of stem cell behavior, while accelerating the pace of drug discovery and the development of tailored therapeutic strategies by offering insights into cellular responses and treatment effects with unprecedented consistency and precision.

While the tissue engineering field splits into scaffold-based and scaffold-free approaches, Ronawk confidently marries both approaches into a third method. Its platform empowers cells to start with a scaffold for essential early support, then progress to organically form tissue-like structures that not only mimic but start to organize into functional organ-like structures. This facilitates healthier cell growth, authentic cell signaling, and natural formation of tissue microenvironments, significantly boosting the potential of all downstream applications.

Ronawk was founded to accelerate next-generation therapies. The innovation of Bio-Blocks lies in their ability to enable cells to cultivate microenvironments that closely mimic their natural habitats.

“Bioprinting is a key area of focus for B9Creations, developing high-precision, customizable 3D printing solutions that enable next-generation therapies. Our technology partnership with Ronawk is already revolutionizing personalized medicine with root cause analysis of specific cancers at top-tier healthcare institutions, like St. Jude Children’s Research Hospital, leading to targeted, personalized treatment for patients, by enabling cell culture that mimics an in-vivo environment outside the body without the need to continually extract tissue from patients. It’s inspiring and humbling to see the human impact of this technological advancement,” said Shon Anderson, B9Creations CEO.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com