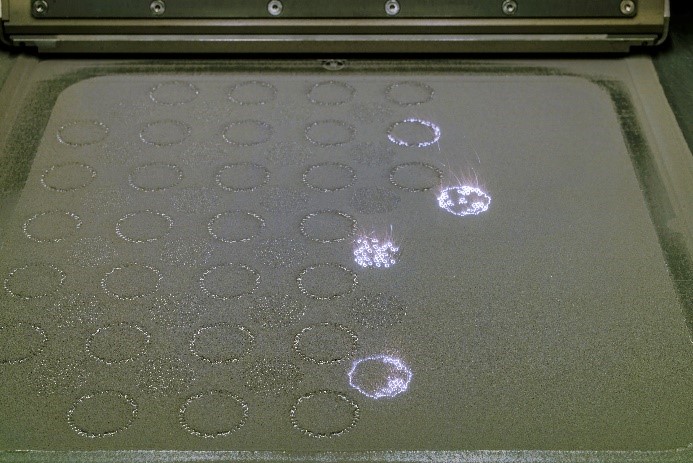

Famous car manufacturer Rolls-Royce has added SLM Solutions AM technology to its production capability. Leveraging the SLM®500 quad-laser machine will enable Rolls-Royce team to achieve build rates up to 171 cm3 while offering automated, closed-loop material supply, recovery and sieving to minimize operator handling of metal powder.

Rolls-Royce already has a certain experience in the additive manufacturing industry, especially in the use of the technology for the aerospace industry. For example, the group will manufacture by 2025 a new core for Rolls-Royce UltraFan® engine design using ceramic matrix composites (CMC) and additive layers manufacturing (ALM). ALM enables the manufacturing of complex engine components with several parts to be fabricated in fewer parts or as a single one.

As you may know, aerospace remains a high-demanding environment due to its certification requirements.

According to Meddah Hadjar, CEO of SLM Solutions Group AG: “Rolls-Royce is very advanced in additive layer manufacturing, with a state-of-the-art approach and expert team working on extremely complex metal additive manufacturing solutions. SLM Solutions recognized the need at Rolls-Royce for a supplier to support with equipment qualification. We work closely to develop products that meet their needs to assure aerospace certified part quality levels. This way the Rolls-Royce team can document their expertise and control of the systems adhering to strict regulations and keep their ambitious and innovative additive production plans on track.”

The aerospace and automotive specialist will exploit multi-laser systems to meet both their productivity demands and to ensure good quality control. Speaking of control, a key requirement of the company was the control of inert gas flow in order to maintain a good atmosphere across the build chamber. SLM Solutions machines enable to meet this requirement. After analyzing these features in SLM Solutions’ machines, Rolls-Royce was satisfied with the sintered wall gas flow that provided optimal results in a compact footprint for their needs.

Neil Mantle, Head of Additive Layer Manufacturing at Rolls-Royce said: ”We are delighted to be working with SLM Solutions and using their quad-laser machines. Rolls-Royce continues to develop our additive layer manufacturing capability to ensure we are at the forefront of advanced manufacturing. We knew that transferring our expertise and knowledge gained from single laser machines to multi-laser platforms would require a close working relationship and SLM Solutions have provided this.”

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

https://pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});