Virginia Tech researchers overcame some long-standing limitations of 3D printing through interdisciplinary research in chemistry and mechanical engineering.

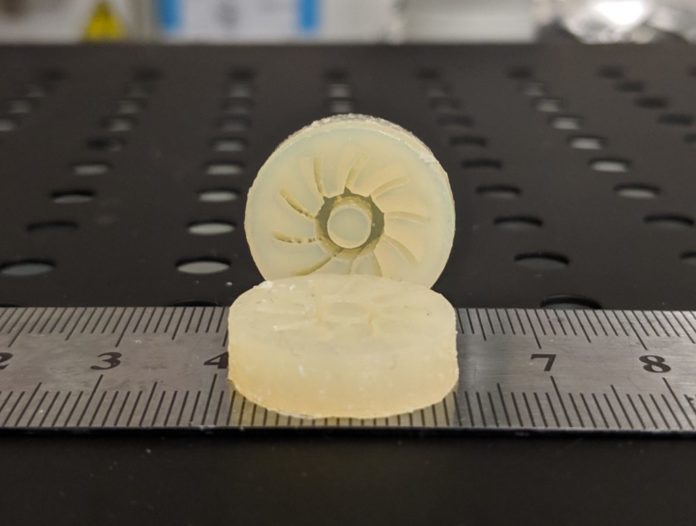

With the goal of unlocking the ability to print a variety of elastic materials with complex geometric shapes, researchers chemically modified liquid latexes to make them printable and built a custom 3D printer with an embedded computer vision system to print accurate, high-resolution features of this high-performance material.

A deep look into commercial liquid latexes

After unsuccessful attempts to synthesize a material that would provide the ideal molecular weight and mechanical properties, Phil Scott, a fifth-year macromolecular science and engineering student in the Long Research Group, turned to commercial liquid latexes.

The researchers ultimately wanted this material in a solid 3D printed form, but Scott first needed to augment the chemical composition to allow it to print.

Scott ran into a fundamental challenge: liquid latex is extremely fragile and difficult for chemists to alter.

The idea of the chemists was therefore to make Scott build a scaffold, similar to those used in building construction, around the latex particles to hold them in place. This way, the latex could maintain its great structure, and Scott could add photoinitiators and other compounds to the latex to enable 3D printing with ultraviolet (UV) light.

“When designing the scaffold, the biggest thing you have to worry about is stability of everything,” Scott said. “It took a lot of reading, even stuff as basic as learning why colloids are stable and how colloidal stability works, but it was a really fun challenge.”

To correctly print the resin, the team built their own 3D Printer based on vat photopolymerization process. However, to avoid printing inaccurate parts, they embedded camera onto the printer to capture an image of each vat of latex resin. With his custom algorithm, the machine is able to “see” the UV light’s interaction on the resin surface and then automatically adjust the printing parameters to correct for the resin scattering to cure just the intended shape.

The researchers said 3-D printed latex provides the conceptual framework for printing a range of unprecedented materials from rigid plastics to soft rubbers, which have been unprintable until now.

“My philosophy is these types of innovations are only achievable when you partner with people who are very different from you,” Long, one of the researchers, said.

“What’s been so exciting about this discovery with Tim’s group is being able to push the boundary of what we assumed was the limit of a printed material’s performance“, another one concluded.

This project is a joint collaboration between Virginia Tech and Michelin North America via a National Science Foundation award aligned with the Grant Opportunities for Academic Liaison with Industry program. Initial results have been published in a journal article published in ACS Applied Materials & Interfaces.

Remember, you can post AM job opportunities for free on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com