Self-sensing allows for the monitoring of critical structures in various sectors including aerospace, construction & healthcare.

Brightlands Materials Center, a Dutch research center, has recently leveraged Anisoprint Continuous Fiber 3D printing to produce composite parts with self-sensing functionality.

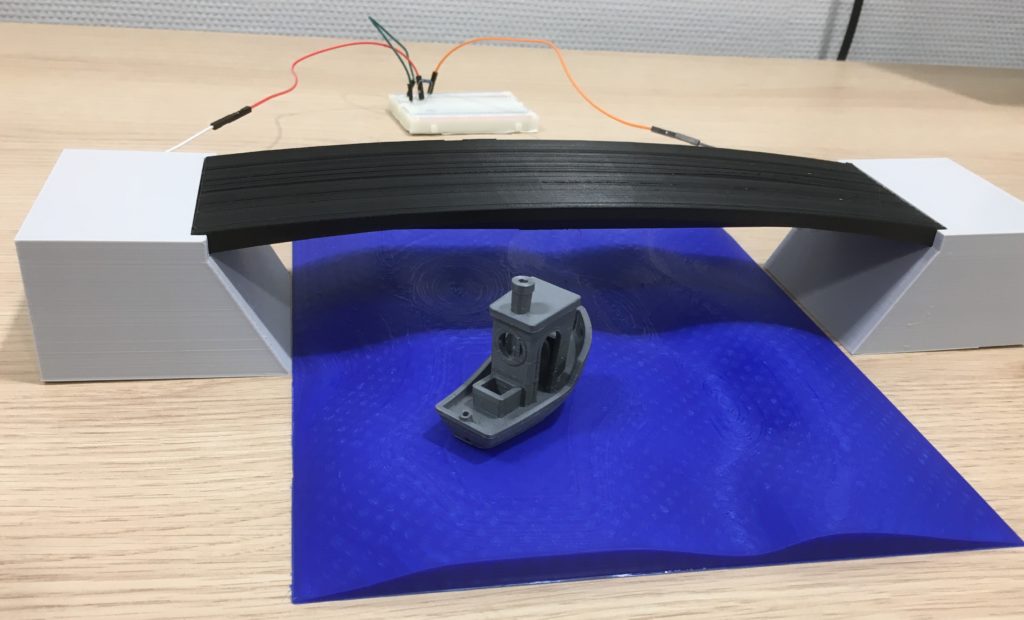

A material with such functionality can determine its own condition, since it is used as a sensor. Polymer-matrix composites for instance that contain continuous carbon fiber, are a type of materials that have self-sensing capabilities based on measurable changes in electrical resistance of the continuous fibers. Such products reveal their importance when utilized in structural health monitoring in airplanes or critical parts of constructions like bridges.

In the healthcare industry for instance, 3D printed self-sensing orthosis or prosthesis can be used as a diagnosis tool to guide patients and provide valuable information to doctors, regarding stress distribution and movement patterns.

During a testing period in aerospace on the other hand, the self-sensing 3D printed part registers the real dynamics and forces that a product needs to withstand. This gives designers and engineers a clearer understanding of what requirements the 3D printed parts will have to meet.

Usually, self-sensing material is made with the traditional composite manufacturing techniques that is the complex several-stages process made by the special equipment. In this specific case, Brightlands Materials Center combines the self-sensing of continuous fiber with fabrication of the composites by additive manufacturing to make it more effective.

Anisoprint continuous fiber 3D printing enables the user to choose any plastic with a processing temperature up to 270°С as a matrix material. The Russian manufacturer of desktop 3D printers keeps exploring various partnerships with companies to strengthen its technology. The latest one in the list was made with materials producer Polymaker.

In this collaboration with the Dutch research center, the Anisoprint Composer A4 composite 3D printer has been leveraged, as it enables to choose any thermoplastic polymer as a matrix, not to mention the freedom of the carbon fiber layout. What makes this AM technology outstanding is the fact that it enables accurate positioning and orientation of carbon fibers.

“The carbon fibers are placed at chosen locations inside the product that form an integral part of the structure. That means that the carbon fiber “sensors” are located where they are needed, and multiple fibers could form a range of sensors throughout the part. This is crucial for sensing, because carbon fiber has to stick out of the part to be able to make connections to the monitoring electronic hardware”, explains Anisoprint.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com