Rapid.Tech 3D | Additive Manufacturing Hub is set to take place at Erfurt (Germany), from 17 to 19 May 2022.

Remember when I told you that “being early is the same as being wrong”? Because, when you are too early, your business is more likely to fail because it is ahead of its time. This happened to be true for many Additive Manufacturing (AM) companies and AM events in our industry but there are always some exceptions that make the rule legitimate. At the time, I was speaking about German OEM voxeljet as an exception to that rule – as it successfully achieved two decades of AM developments -, today, I will speak about Rapid.Tech 3D | Additive Manufacturing Hub as another exception, as the industry event will very soon celebrate two decades in the organization of an industry event that has shaped the way companies have grown their knowledge and use of AM technologies.

In the case of Rapid.Tech 3D, it’s fair to say, it’s the small things that were repeated on a certain basis that make all the difference. Indeed, AM has been introduced for the first time at Rapid.Tech 3D in 2004. It was just a topic that raises the interest of a few insiders. Since then, every year during the spring, professionals from various industries gather at Erfurt, in the fast-moving heart of Germany, to discuss, exchange and learn more about AM. Today, AM has become an established solution with a growing technological, economic, environmental and social impact and Messe Erfurt GmbH is ready to host the 2022 edition of this technology-dedicated event– an edition that 3D ADEPT Media joins as a proud media partner -, an edition that is set to take place at Erfurt (Germany), from 17 to 19 May 2022.

“Since the first edition in 2004 Rapid.Tech 3D has evolved from a specialists’ conference to a renowned trade show and conference. We started as a meeting place for the rapid prototyping industry in central Germany and developed to the leading hub of Additive Manufacturing in the German-speaking area” Diana Keucher, Head of Department Trade Fairs, Events & Service recalls.

Under the motto ‘Understand. See. Experience’, this 18th edition of the event ambitions to highlight what’s being done in practice in industrial 3D printing and showcase the latest products and services provided by solutions’ providers. After almost two years of digital events (due to Covid-19), not only regulars of the show are looking forward to meeting in person, but professionals across industries are simply looking for in-real life exchanges.

According to Keucher, “the digital event in 2021 was a good way to stay in contact with [the] AM community as well as to give a platform for knowledge sharing.” “Nevertheless, the level of demand for live events is as high as never before. Therefore, this year we are looking forward to holding an onsite event again. For participants who cannot make it to Erfurt this year, we will offer a live stream of the main conference track”, she adds.

So, what can we expect from this 2022 edition?

In addition to the exhibition arena, Messe Erfurt GmbH has planned a wide range of supporting programmes for the three days of the event. Beginners or advanced users in AM could discover the creativity of experts across a wide range of industries at the 3D Pioneers Challenge (International design competition for additive manufacturing technologies 2022), take part in workshops that best meet their needs, or listen to industry insiders at the 3D printing conference.

Rapid.Tech 3D will host the 7th edition of the 3D Pioneers Challenge. The latter is basically a creative meeting place for start-ups as well as experts and industry giants in additive manufacturing. “The largest international design award of its kind is endowed with a prize money of EUR 35,000”, Diana Keucher states.

Workshops on the other hand, put you in a context where you learn in a very interactive way with organizations.

Lastly, speaking of conferences, the Head of Department Trade Fairs, Events & Service says they will welcome more than 70 international speakers who will provide plenty of touchpoints for creative exchange and the opportunity to make new contacts.

“AM experts from Airbus, Autodesk, German-Emirati Institute, nFrontier, Porsche, Procter & Gamble, Sauber and Toolcraft will present the latest product and process applications. Last but not least we will offer a lot of networking possibilities such as our network evening or booth receptions”, she adds.

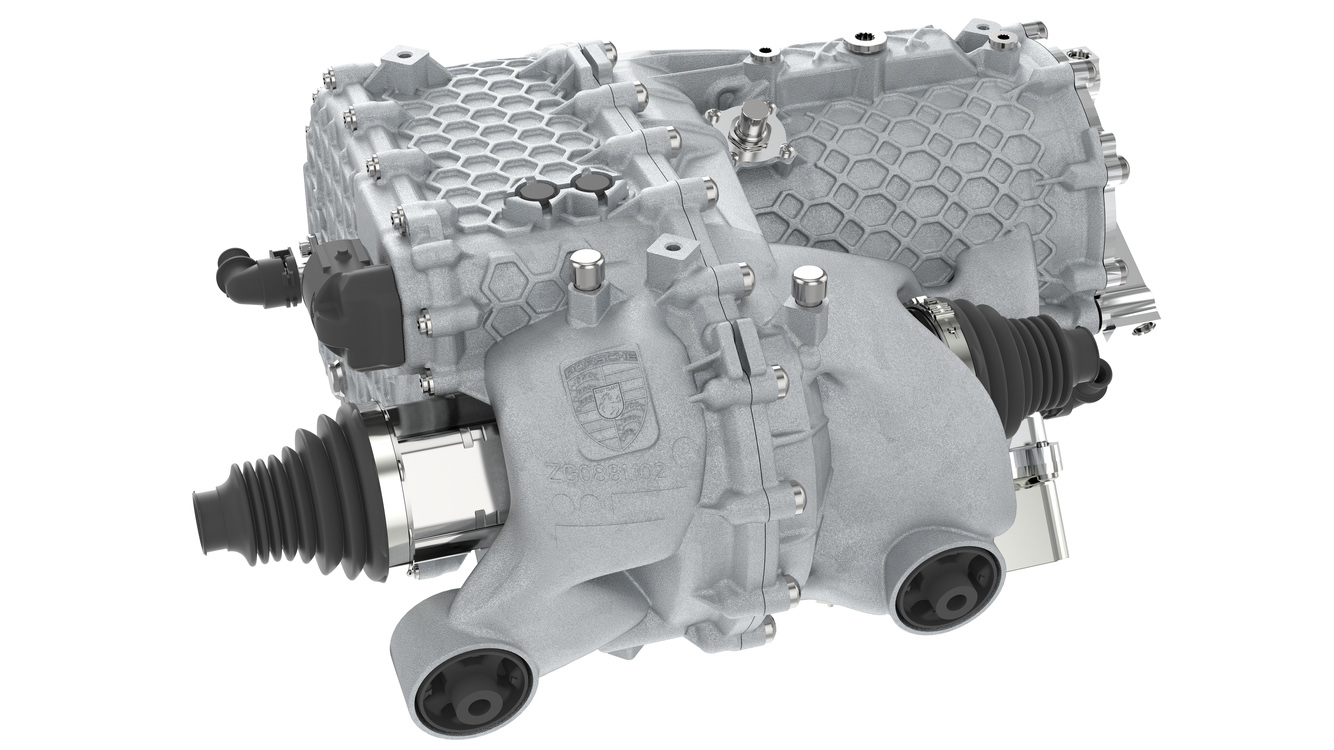

Be it in aerospace, automotive or manufacturing, the industry insiders Keucher just mentioned are currently applying AM technologies in a way that is worth discovering. Porsche for instance, has successfully created an electric drive housing using 3D printing : Heilfort, a graduate engineer for automotive engineering, will be discussing the effects and experiences gained during the project in a keynote speech.

Airbus Helicopters has been additively manufacturing parts for aircraft doors for about three years. The latch shafts are used in the A 350 passenger aircraft. “We started identifying components for metal 3D printing in 2017 and kicked off with this kinematic part. Compared with the conventional version, we save about 45 percent in weight and 25 percent in costs by so far integrating ten parts into one component. Around 3,500 shafts have been produced and the first of these have already been installed,” reports Frank Rethmann, Head of the Industrial Service Center 3D Printing department at Airbus Helicopters. In a keynote address on the opening day of Rapid.Tech 3D, he will be talking about this and other series applications, as well as the challenges involved.

Bernhard Randerath, CEO of the newly established German Emirati-Institute – Technologies 4.0 (GEI), will make a focus on “Transport interiors of the future”. “Be it planes, cars, trains or ships – modes of transport have similar requirements when it comes to interiors and components that are similar constructed. 3D printing can deliver new designs and functionalities and synergies in parts production for the various transport types. From individual elements to printed cabins, the entire product range can be reproduced – without the need for toolmaking or extensive logistics,” Bernhard Randerath explains. GEI is in the process of turning this vision into reality. “We will be building a factory that will use Industry 4.0 technologies to develop intelligent interiors for the transport of the future, and produce them sustainably. Additive manufacturing will play a major role in this,” says the GEI manager, explaining the German-UAE project. A site is currently being sought in Germany. “We’re looking for a region that is undergoing structural transformation, moving away from coal and towards the industries of the future,” Bernhard Randerath explains, adding that the factory is scheduled to start operations in 2025.

These keynote speeches are just a few examples that illustrate how well the status and progress of rapid prototyping up to the implementation of end products with the help of additive manufacturing is increasingly becoming a reality…and the only way you can appreciate the veracity of these words is by attending the upcoming Rapid.Tech 3D event.

“After a purely digital Rapid.Tech 3D 2021, we look forward to experiencing the unique triad of trade fair, conference and networking LIVE as a face-to-face event in Erfurt/Germany from 17 to 19 May 2022”, Diana Keucher concludes.

If you want to have further information about the show, you may visit Rapid.Tech 3D’s website.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com