Paulo, a specialist of the heat-treating industry, just acquired Quintus Technologies Hot Isostatic Press (HIP) technology. As Pierre Forêt explained in a recent Opinion of The Week, such type of technology utilizes temperatures in a contained high-pressure atmosphere to eliminate internal porosity and voids within cast metal materials and components.

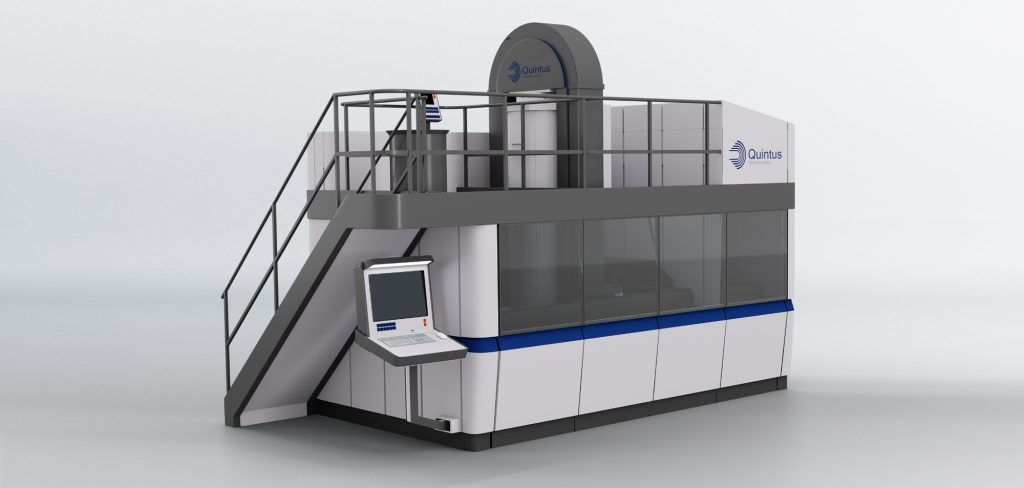

The model QIH 122 M URC® of Quintus integrates its proprietary uniform rapid cooling (URC), a feature that improves material properties in additive manufacturing and investment casting. Furthermore, it integrates a work zone of 26.0 inches (660 mm) in diameter and 68.9 inches (1,750 mm) in height. It operates at a maximum temperature of 2,552°F (1,400°C) and maximum pressure of 30,000 psi (2,070 bar).

According to Quintus, the solution has been configurated in a way that the user saves space and energy, which facilitates building and civil work and reduces infrastructures investment. Furthermore, the biggest benefit of this model relies on the URC feature that eases every stage of the process at the material densification level. In other terms, the feature enables the combination of heat treatment and cooling in a single process, hence the designation of High Pressure Heat Treatment.

“We see the market for HIP expanding, with a large part attributed to additive manufacturing,” Scott Herzing, Paulo Vice President Engineering, comments. “We have the leading material knowledge and process expertise to help our customers in this area. The ability to combine HIP and heat treatment will allow us to offer one-stop-shop thermal processing solutions, with faster turnaround times.”

The two companies also signed an agreement that will enable Paulo to promote the use of the HOHT process.

“Paulo was very intrigued by our ability to offer a complete partnership: the system itself, the Quintus Care program including application support, and the marketing agreement,” says Jan Söderström, CEO of Quintus Technologies. “With this partnership they see the possibility to enter the market in the best possible way.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter! Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com