Three years after their first appearance at formnext, machine manufacturer PULVERMEISTER returns to Frankfurt, with a new post-processing solution for 3D printed parts.

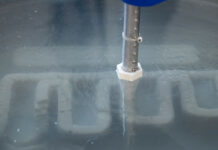

Named Typ4, the new machine is based on the same-patented technology as its predecessors. The modular system processes entire build compartments in the 20l class or smaller of powder-based AM plastic. The loading mechanism is like a big funnel, which facilitates the loading of the entire build chamber in one move. Unpacking, breaking of the powder cake as well as depowdering of parts are done in a stainless steel vacuum drum. A vacuum is also used to transport the powder. This circuitry is contamination free, therefore enables refreshing and further use of the powder.

Moreover, four parameters enable to control the degree of detachment of the powder from the built surface: inclination of the drum, air pressure of the injection nozzle in the drum, rotation speed of the drum as well as time control of the process.

“The adhesive strength of the powder, like its decomposition (or degradation), is linked to the cause of heat absorption in the build process. The more heat the powder absorbs at a particular point, the more it will adhere to the adjacent contact surface and the less likely it is usable for refreshing (degradation). By fine-tuning the 4 parameters mentioned above, it is possible to control how much powder is detached and thus reused, and in what quality”, a press release reads.

“The trade-off is how much a part should be stressed and how long it takes to get the required amount of used powder. This fact will become even more interesting if in the future when the mixing ratio of new and old powder changes in favour of a lower use of new powder”, the company explains.

On the other hand, the operator can also de-powder more powder than he wants to reuse. To do so, he simply connects to another vacuum and continues the process to remove degraded powder from parts.

As far as certification and quality control are concerned, it should be noted that the machine complies with German machine and safety guidelines. For example, when opening (the lid or the drawer) the whole machine stops immediately for safety reasons. If the vacuum fails, the air pressure of the nozzle turns off immediately. Not to mention that, the inclination of the drum can also be done by rotation of the second axis. Feeding and removing air/ powder through both axis is currently only seen in the PULVERMEISTER machines.

On the other hand, the manufacturer also uses the stress factor for quality control. “If something went wrong in the manufacturing process, the parts are more likely to break. This was already saving a considerable amount of money as we found that we then had received degraded powder”, the company reports.

So far, the the PULVERMEISTER system has already processed more than 100,000 parts without any modification. According to PULVERMEISTER, for a 16l PA11 Black for instance, EOSP110 build tray with deep cavity parts, it takes about 15 minutes . This means 16 build compartments of the above mentioned parts in one 8 hour shift, with 100 % safety margin. Also, for one day building, the operator will require one day cooling on an EOSP110, which then results in one Typ4 easily processing 32 machines.

The Typ4 is already available to purchase for 20.000,- EUR. First shipments are scheduled for Q1/2022.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com