“Due to the wide range of possible tasks, the robot-integrated depowdering system is a custom solution, not a series machine,” Andreas Hartmann, Cofounder & CEO of Solukon.

Seven years ago, in one of my first conversations with Andreas Hartmann, Co-founder and CEO of automated depowdering company Solukon, he emphasized a key challenge in depowdering: this step was still manual and highly time-consuming. Together with Dominik Schmid, his co-founder, Hartmann set out to tackle this issue: making automated depowdering Solukon’s core mission. For the past decade, the company has been meeting the stringent production demands of aerospace, automotive, medical, energy, and other regulated industries with its automated depowdering systems. Now, Solukon is going one step further: envisioning a depowdering solution powered by robotics. In the following article, Hartmann explains the why and how of this concept and what it could mean for the future of depowdering.

There is a subtle distinction between a depowdering system that uses a robot and an automated depowdering system. However, understanding why AM users would need a robot for depowdering might come down to understanding the reasons for automation.

For Hartmann, 4 reasons can explain the need for automation:

- The work is too complex for humans.

- The work is too dangerous for humans.

- Consistent quality cannot be ensured through manual work.

- Production needs to be accelerated.

“If automation can eliminate a downstream quality assurance step, this is always a major achievement. For example, if powder residues are detected in the depowdering station and not only in the downstream process step such as heat treatment, a lot of time and effort can be saved.

Robots are suitable for supporting all four of these challenges in automated powder processing,” he explains.

The truth is, the concept of a robotic depowdering system is not nascent. Two years ago, the German machine manufacturer and British robotics technology company Rivelin, shed light on the possibilities of such a solution. In the market, various OEMs are also exploring the idea, which makes us realize that robots can perform a wide range of tasks.

What tasks can a robot fulfil when it comes to depowdering and how?

In general, robots can fulfil tasks inside and outside the depowdering chamber.

There is growing interest in robotic surface and part cleaning in the market. As a result, R&D efforts are increasingly focusing on improving perception and control capabilities.

“Robots inside the depowdering chamber fulfil primary working steps or quality control. Robotic tasks outside the chamber (e.g. loading the part) are secondary tasks (which means they do not belong directly to the process)”, Solukon’s CEO outlines.

By playing the role of a “third arm”, Hartmann identifies 6 tasks a robot can perform inside the depowdering chamber:

- “The Solukon system is primarily designed to remove powder from the internal channels of the component. However, static charge or agglomerations due to sintering, also cause powder to adhere to the outside of the component. The best way to remove these deposits is to blow them off with a compressed air gun. If this step is not to be carried out manually via glove access, this automated finishing task is an ideal task for the robot.

In addition, the robot could perform surface finishing with dry ice blasting.

- For components with a series of different openings, robots can also be used for targeted blowing out of the openings to loosen the powder clumps. This is a requirement that was brought to Solukon directly from the market (space).

- With particularly large components, it is possible that the vibration is not fully transmitted to all areas of the part. Local, targeted and moderate knocking, executed by a robot can help here.

- For inspection and quality control we also see high potential for robot integration. Based on a predefined matrix, the robot checks the part for cleanliness, potential damage (e.g. cracks due to thermal effects, shape deviations) after completing the depowdering process. Of course, the robot must be equipped with appropriate sensors and cameras for this purpose.

- Further tasks for a robot are finishing working steps like the concept we’ve shown together with Rivelin Robotics: Rivelin uses standard finishing tools like belt sanders, micro grinders, ultrasonic polishers, nippers and pneumatic hammers – only manipulated by a robot. Having such tasks performed in the Solukon system would have the advantage that downstream process steps could also take place in an explosion-proof and, if necessary, inert environment.

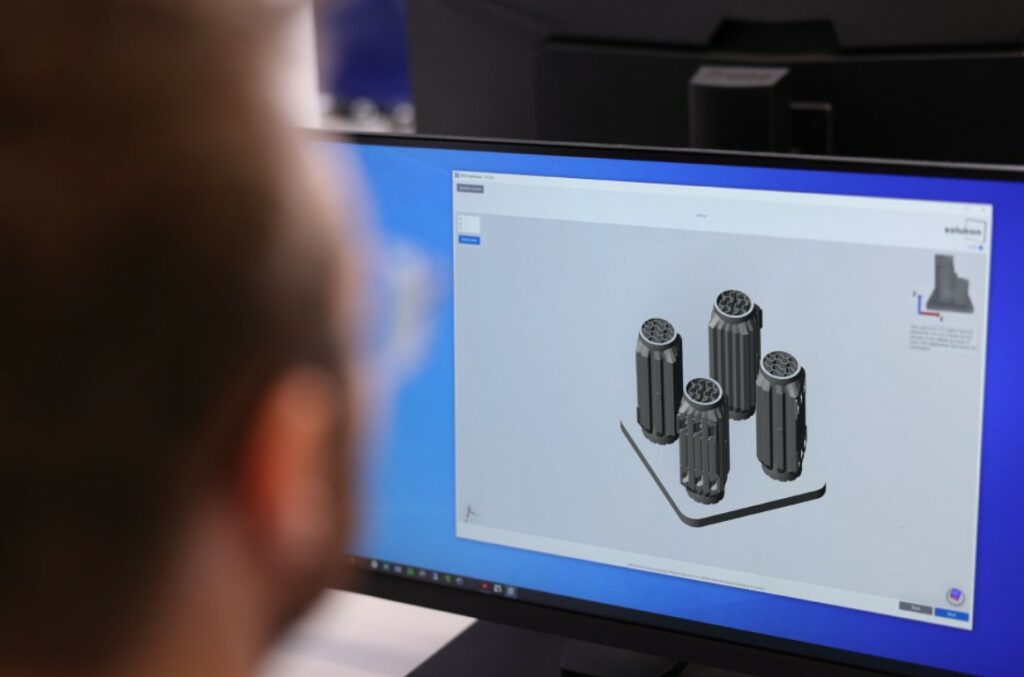

- Theoretically, we can use the robot and a new type of technology for measuring the flow of air to check whether the channels are powder-free. This option is currently under development at Solukon.

Due to the wide range of possible tasks, the robot-integrated depowdering system is a custom solution, not a series machine.”

These tasks emphasize the attractiveness of robotic assistance in depowdering. When we think of complex geometries and internal channels where an automated depowdering system needs to remove powder from, we expect further value from a robot when it comes to batch processing, ergonomics, and operator safety, or even integration with digital workflows.

“It’s rather a mixture of many different factors that make a robot inside the Solukon useful. Firstly, parts with many different openings. Also, when the customer needs sufficient depowdering for a big batch, or if he requires the process to be 100% automated. Furthermore, high demands for process transparency and repeatability (e.g. in space industry),” Hartmann comments.

As you may guess, production workflows in AM vary from one application to another, but also from one AM process to another. Given the fact that a robot must not act as a standalone device but as part of a closed, traceable workflow, there is a need for communication with upstream and downstream equipment.

For instance, communication with the 3D printer is important to know the orientation of the build, the geometry of the parts, and any special handling needs (e.g., fragile zones). It also helps to ensure the robot grips the build plate safely and follows the correct depowdering program.

So, how is it done?

“Through OPC UA”, Hertmann replies. For those new to the field, Open Platform Communications United Architecture (OPC-UA ) is a platform that provides the necessary infrastructure for interoperability across the enterprise, from machine-to-machine, machine-to-enterprise and everything in-between.

This means that “the robot-integrated depowdering systems can be connected with the digital dashboards of the printers or the MES system.”

At this stage, “precise calibration of the robot movements is necessary for the integration of the robot. This development effort is only worthwhile if comprehensive knowledge of the “conventional” automated depowdering process without robots is already available. Where did powder residues remain in the component despite all efforts? At which points outside the component did a particularly large amount of powder adhere? etc.”

This is a requirement for integrating the robot into the depowdering process.

The road to commercialization: Examples and productivity metrics

Two years ago, when Solukon joined forces with Rivelin to explore the possibilities of a robot-integrated depowdering system, both companies had realized that AM users require specific things like localized and targeted vibration for depowdering, robotic compressed air blasting, robotic sensing solutions to check the airflow of the cleared channels, and powder blasting surface enhancement.

Hartmann confirms today, they are in discussion with several prospects and customers.

“This is not an off-the-shelf solution and will probably be a custom solution because the robot tasks are very diverse and individual. In addition, there is a high degree of component dependency in the robot’s area of application.

Industries with high throughput (e.g., automotive) or high requirements (space) are particularly suitable.

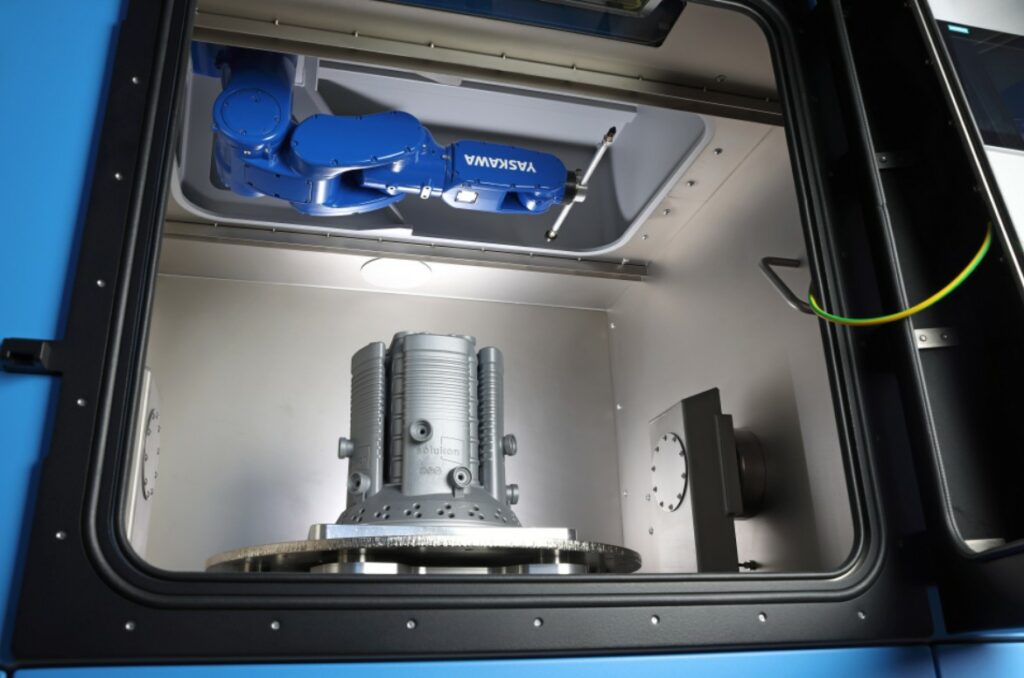

We are very close to achieving a depowdering system with a robot: At Formnext 2025, we will exhibit an SFM-AT800-S with automated robot finishing (and automated part loading). For a seamless process the machine is equipped with an automated front door and a zero-clamping system for automated part mounting.

Yaskawa is the robot supplier, Grenzebach is the supplier of the transportation vehicle,” he outlines.

Behind the scenes, the company is developing an automation concept in which a component moves through a Grenzebach transportation system into the depowdering system. The transportation system pushes the part into the Solukon system, where it is mounted using an automated zero-point clamping system, and the depowdering process begins. The transportation and depowdering systems communicate via OPC UA. While a robot is not yet part of this setup, its integration could be considered in the future.

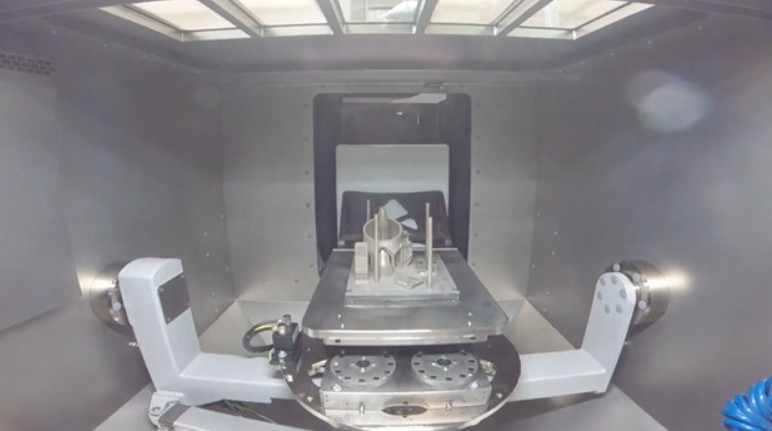

Looking at concepts that have passed the research level stage, it is now possible for the Solukon automated depowdering system SFM-AT800 to constantly communicate with a control center while being loaded by a robot. For this purpose, it has been equipped with a special loading door and an automatic clamping system.

An example that is worth mentioning is the robot-integrated concept established at Fraunhofer Institute for Machine Tools and Forming Technology (IWU) located in Dresden, Germany. In this production center, a Solukon SFM-AT800 with an OPC-UA interface is part of a modular robot cell.

In Hartmann’s view, “this fully automatic robot cell serves as a characteristic example for downstream processing. Besides the Solukon depowdering unit, the robot cell consists of a system for optical analytics of the geometry and a system for support removal. The different stations communicate via OPC-UA. Part loading and further tasks referring to metal cutting are performed by the robot.”

This example certainly allows AM users to project themselves into the future. The only thing it does not show is quantifiable measurements that gauge the effectiveness and efficiency of a robot-integrated depowdering system.

While we hope to discuss accurate data regarding productivity metrics with Hartmann in the future, he already confirms that, “over time, throughput, i.e., the number of parts depowdered per machine using robots, could increase significantly. This is particularly true when components are cleaned in series [while] SPR-Pathfinder® and the robot are working in perfect harmony with each other. Especially if you have a whole batch or at least more than one part on one build plate: This would fully exploit the potential of the fact that the SPR-Pathfinder® and the calibrated robot treat the many components as one and clean or finish them quickly.”

“With a standardized process for finishing (blowing out and blowing off) and quality control, the build job can be moved on to the next steps of post-processing more quickly, and the depowdering system can be loaded with new parts for depowdering more quickly. If quality checks are already carried out by the robot during depowdering (saving an entire process step), rejects are identified earlier.

Additionally, once automation is established, multi-shift operation is possible (robots can unload at inconvenient times throughout the night).

In summary, robot integration in depowdering always means saving work steps or bridging machine downtime,” he says.

Concluding thoughts

Our conversation with Solukon highlights that robot integration in depowdering is far more than “hanging a robot onto a system.” For now, its use remains highly component-dependent.

Developing a reliable “robot recipe”, as Solukon has done with SPR-Pathfinder®, will require close collaboration between the company, technology robotic partners, and AM users.

These insights point to exciting automation concepts that we look forward to exploring further with Hartmann. In the meantime, attendees at Formnext can exchange ideas on the topic directly with the company at booth 12.0 D71.

This content has been written in collaboration with Solukon.