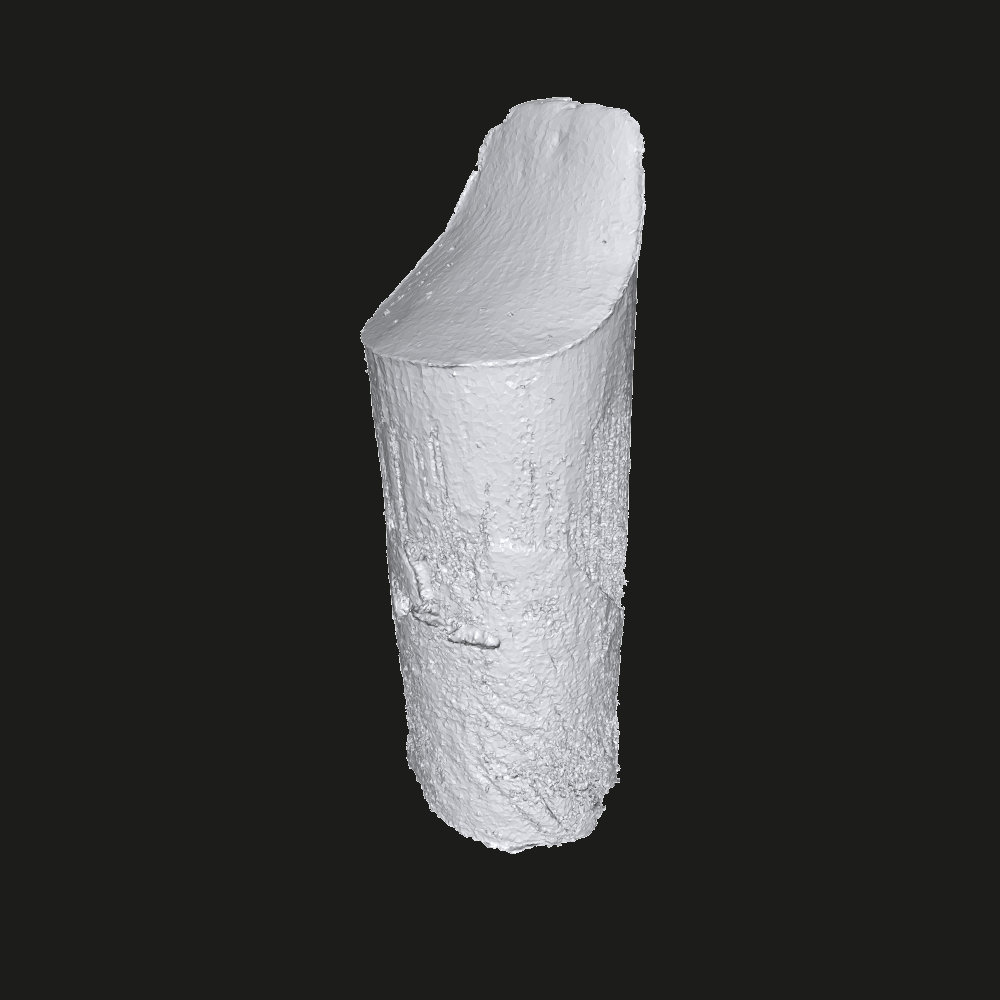

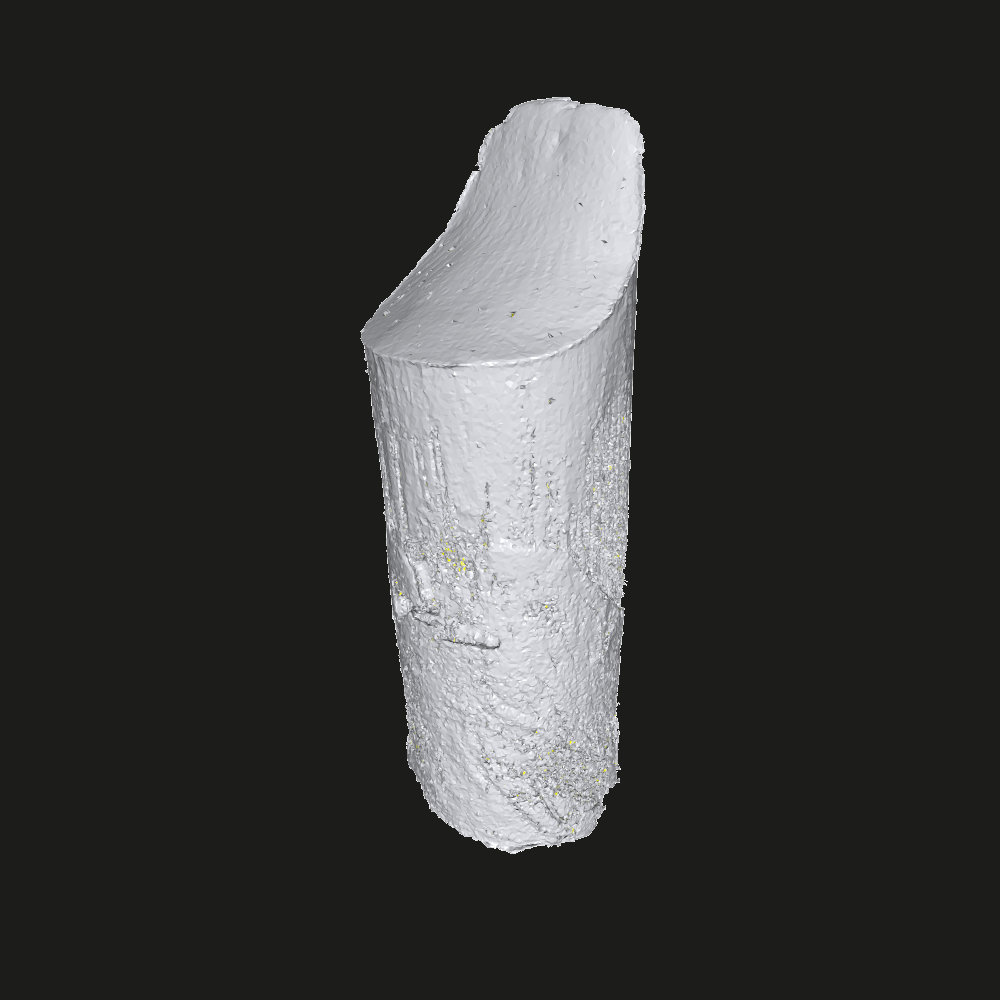

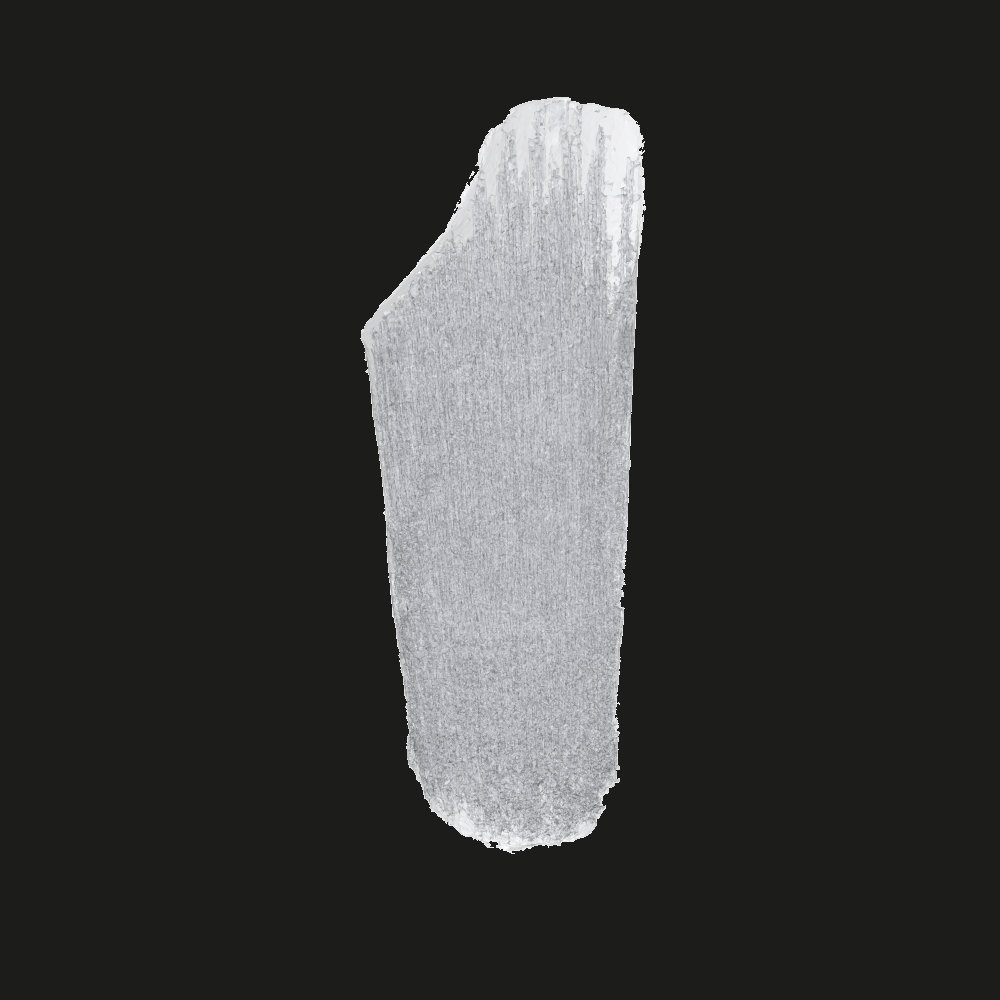

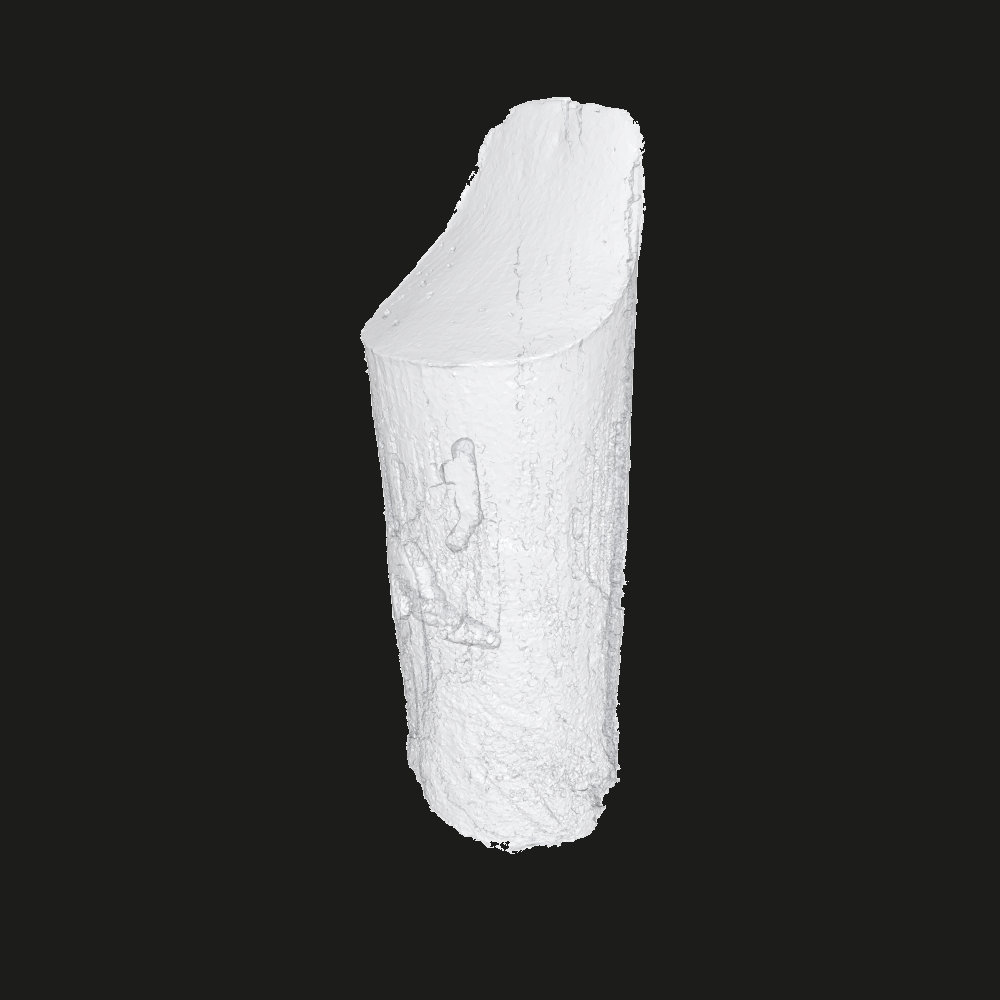

The Department of Engineering Science at Oxford University had a complex mesh created from a 3D scan of a severely damaged part of a 17th century flute that was impossible to 3D print.

The instrument in question, a recorder made in London, had an extremely dry and porous wooden block in the mouthpiece damaged by insects. The CT scan provided by Cranfield University and converted to a STL file was not at all printable. It contained a huge number of errors including self-intersecting triangles and had lots of internal detail not required for 3D printing.

Peter Walters, 3D printing engineer at Oxford University, said “We tried to rebuild the model of the block using several other mesh software tools without success. However the unique capabilities and specialist knowledge of Polygonica enabled this to be achieved with ease.” For those who do not know, Polygonica is a solid modelling software toolkit for processing polygon meshes.

“We used Polygonica’s shrink-wrapping algorithms to create a faithful representation of the outer surface of the original model, whilst removing errors and unwanted internal structure. This resulted in an accurate and printable STL file,” said Dr. Simon Vickers, Senior Developer at MachineWorks Limited.

The Pitt Rivers Museum houses a collection of over 7,000 musical instruments from around the world and receives multiple requests for the instruments to be played. Unfortunately, many of the instruments are either too fragile to be played and risk being irreversibly damaged, or else have been contaminated by old pesticide treatments which now pose a health risk to anyone wanting to play them.

The Department of Engineering Science at Oxford University and the Conservation Department at Oxford’s Pitt Rivers Museum are collaborating to create playable replicas of antique musical instruments using 3D scanning, reverse engineering and 3D printing. The team includes Andrew Hughes and Jeremy Uden from the Pitt Rivers Museum and Alfonso Castrejon-Pita, Peter Walters and Benjamin Fudge from Oxford University Department of Engineering Science.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com