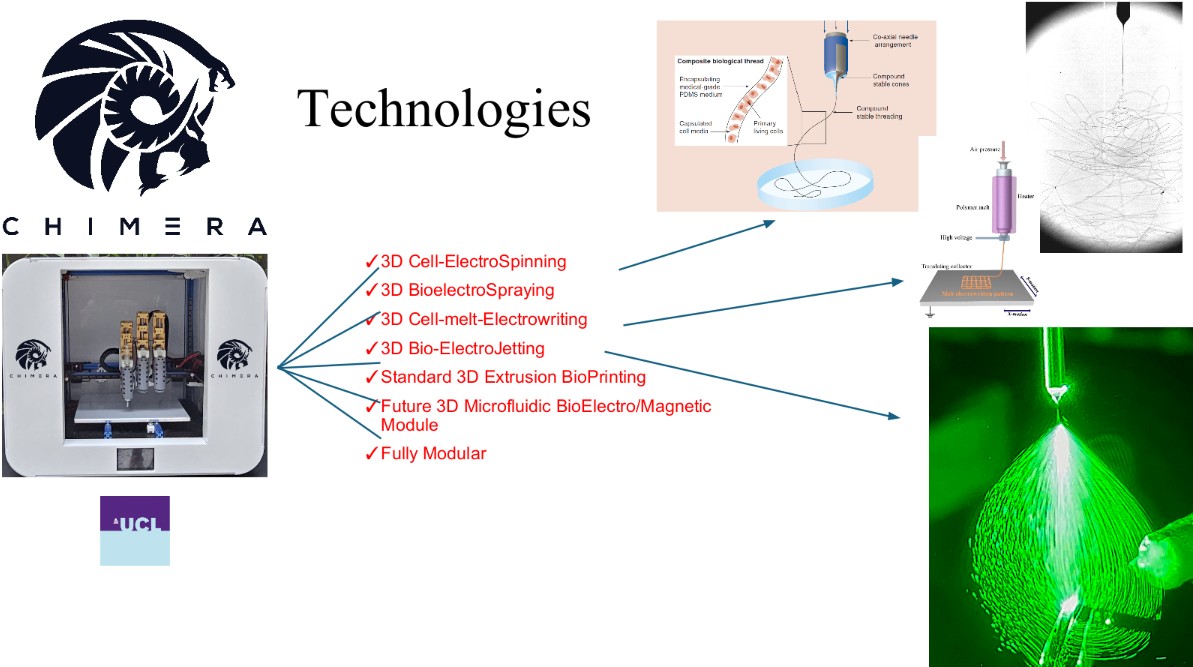

Ourobionics BV, a 3D bioprinting company that you may have discovered through this dossier, has launched CHIMERA, a bio-fabrication & biomanufacturing platform that integrates five advanced technologies into a single machine.

By combining 3D Bio-ElectroSpraying, 3D Cell-ElectroSpinning, 3D Bio-ElectroJetting, 3D Melt/Cell ElectroWriting, and Standard 3D Extrusion BioPrinting, the system aims to accelerate multi-complex tissue production with stem cells, organoids, genes and more.

The launch of CHIMERA follows a successful round of VC investment in 2024 led by OostNL & the €1 Billion NXTGEN Hightech program marking a milestone in the field of bio-fabrication and cell-based biomanufacturing.

CHIMERA would be a good candidate for tissue engineering, regenerative medicine, cell-based biomanufacturing (cell-therapy/cellular agriculture), and the development of advanced biomaterials. According to Ourobionics, the system would deliver speed, precision, and versatility required to overcome many of the current biofabrication and biomanufacturing technology limitations.

“Our goal with CHIMERA is to launch our novel technologies onto the market and address the fundamental challenges in biofabrication and biomanufacturing—cell viability/function, speed, nano-scaffolding, encapsulation, and scalability—while offering unprecedented modularity and process versatility,” said the founder & CEO John Zandbergen. “ We have also started the fundraising for our next round with VCs & angels in HealthTech, ClimateTech & DeepTech sectors so that we can truly scale at a production level for multiple cell-based biomanufacturing industries.”

Key features of CHIMERA include:

- Five modular 3D bio-fabrication technologies in one machine, offering unparalleled versatility for a wide range of applications. [3D Bio-ElectroSpraying, 3D Cell-ElectroSpinning, 3D Bio-ElectroJetting, 3D Melt/Cell ElectroWriting, and Standard 3D Extrusion BioPrinting]

- Up to 98% cell viability is published across 56+ cell types, including stem cells and full embryos, enabling the creation of complex human or animal tissues.

- 30X faster speeds than traditional extrusion bioprinting, with each module achieving 1cm³ in just 1 minute using the bio-electric field.

- Nanoscale resolution (up to 50nm) without cells, enabling highly detailed structures and scaffolding.

- Cell or Cell Cluster Encapsulation to advance production capabilities in cell therapies and other fields of cell-based product biomanufacturing (cellular agriculture/textiles). Also published for embryo encapsulation that remains viable and develops fully.

- Gene or Gene Cluster Encapsulation for synthetic biology, drug development, and biomanufacturing

- Ability to work with almost any biomaterial, including those with high or low viscosity.

- Proven cellular, metabolic, and pluripotent preservation—ensuring cells remain viable and fully functional, a key challenge in current bioprinting techniques based upon impact of extrusion/shear stress.

- Early Stage Access to “3D Microfluidic Bio-Electro/Magnetic modules”

The core bio-electrofabrication technologies utilized by CHIMERA have already been successfully published in over 150 scientific journals, showcasing its ability to preserve cellular and metabolic integrity while enabling rapid fabrication of complex, high-fidelity tissue structures. The platform’s diverse bio-fabrication capabilities enable users to work with a broad range of applications, from gene encapsulation and drug testing to stem cell therapy and organoid development.

In addition to its current suite of technologies, early-stage ambassadors will gain access to future 3D Microfluidic Bio-Electro/Magnetic modules, further expanding CHIMERA‘s potential applications across the bioeconomy.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com