Strengthening conventional cleaning business with post-processing for Additive Manufacturing.

There are several ways to enter the additive manufacturing market: while big players mostly decide to acquire SMEs, others follow all the steps of an entrepreneurial journey and develop their own products.

OSSBERGER GmbH & Co. KG is one of those big players that has a deep footprint in the engineering industry. However, unlike most players that belong to the same league, the company’s recent entrance in the AM industry is the result of an in-house experience that outlined the necessity for a reliable post-processing equipment.

Before we delve into this point, let’s mention that the family enterprise has built a solid reputation in Hydropower Technology. With over 10 000 turbines installed across the world, it’s fair to say the company has been able to improve the quality of life for millions of people with eco-friendly and renewable energy.

Over time, the German machinery maker has also built up extensive expertise in the Plastic Technology. Its plastics processing machines have allowed for the reduction of automotive components, saving this way, significant resources in fuel and energy consumption as well as global CO2 emissions.

The third business unit Surface Technology manufacture cleaning systems that work without chemical agents leads to less waste and less environmental impact, thus saving energy and providing a cleaner, eco-friendlier system than conventional installations. This technology, which also uses vibration at its core, has been used worldwide for 17 years.

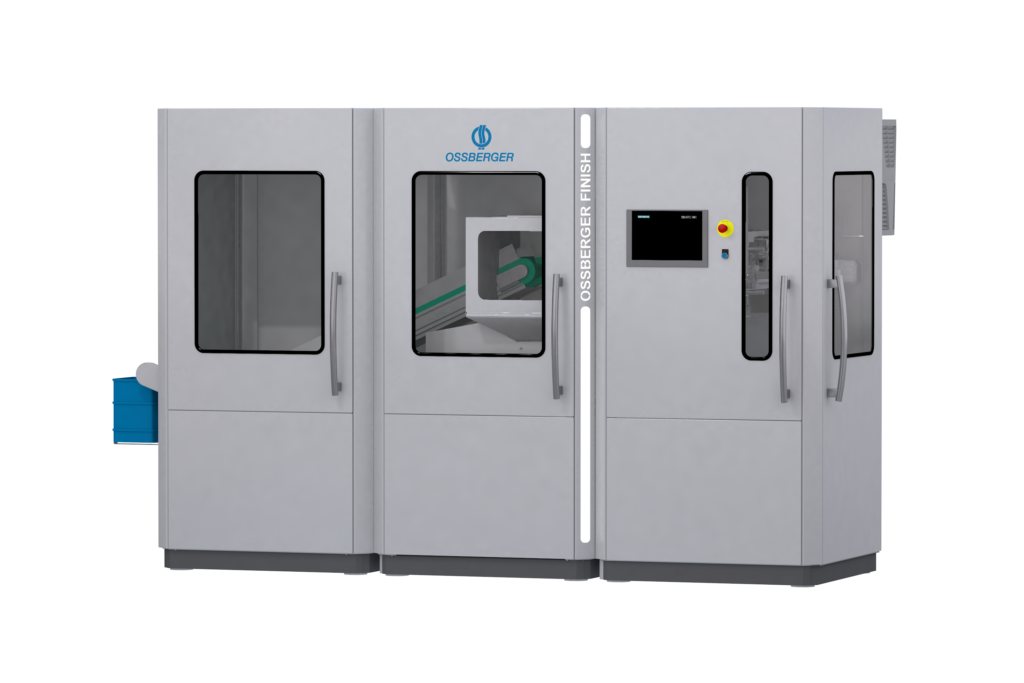

Additive manufacturing comes into play into the company’s activities in 2019 when Surface Technology developed the OSSBERGER FINISH machine platform.

The company was using a powder-bed technology for tooling and other machine components. They quickly realized the intense work required by post-processing.

Rather than investing into an external post-processing system, they leveraged their expertise in machinery and surface technology to develop a post-processing solution that marked the debuts of their AM activities.

“We have produced tools with SLS technology. When we came across the issue of post-processing for AM, we’ve seen a perfect match of our vibration technology and the dry-cleaning requirements of parts produced in powder bed technology. So, we worked on a solution that we exhibited at Formnext 2019 for the first time. During the show, we met EOS GmbH and we continue the product development of the machine with them this year. With our OSSBERGER FINISH Platform, we provide scalable automatable solutions for unpacking, de-powdering and cleaning of powder-bed printed parts”, Markus Garscha, Business Unit Director, explained.

The OSSBERGER FINISH Machine Platform

“Unpacking, de-powdering and cleaning”, these are the key bottlenecks in using additive manufacturing (AM) as an industrial process. Adding automation to these tasks is giving the opportunity to operators to enable viable use of AM in their production environment.

The only thing is that, post-processing of 3D printed components can be quite complex. Metal 3D printed parts for instance do not require the same equipment than polymer 3D printed parts which require a more specific equipment, not to mention that some metal 3D printing processes sometimes require various post-processing solutions.

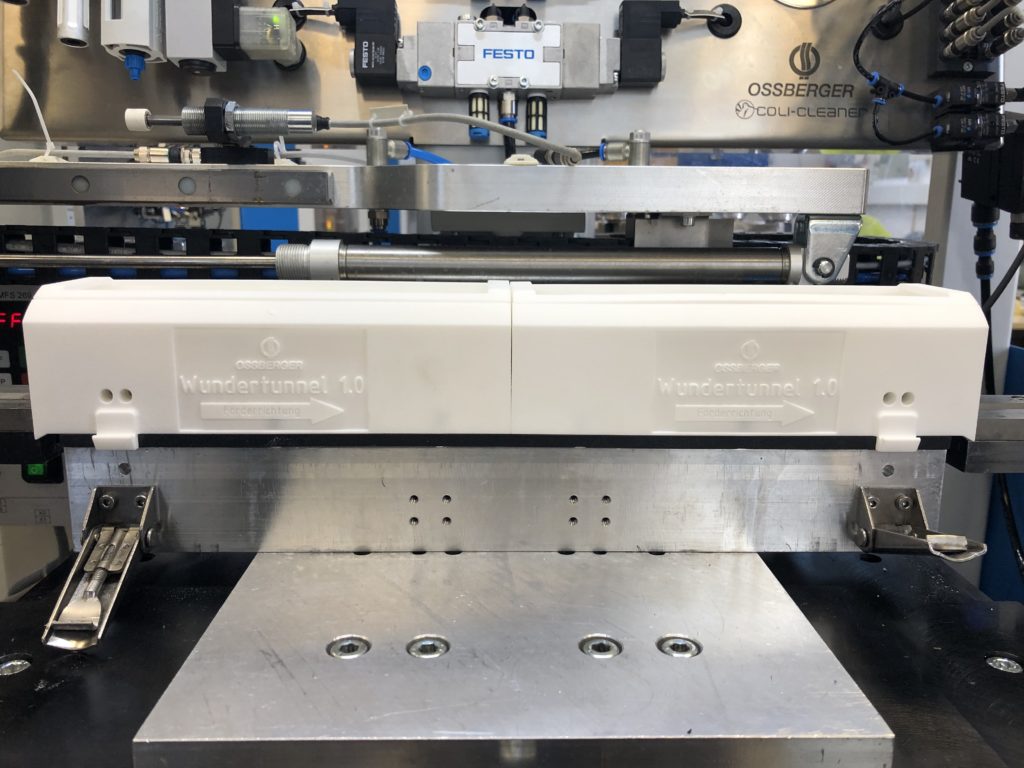

OSSERBER GmbH has decided to focus on powder-bed based AM technologies to develop its equipment. OSSBERGER FINISH’s patent-pending technology uses Modulated Vibrations and Vacuum Airflow. The Modular machine platform can be used without compressed air and any blasting material. It has been qualified by EOS and best suits the post-processing of parts with fine details.

Inside the post-processing machine

“Our machines can be integrated in a fully automated smart factory environment: e.g. an autonomous print container handling system or connected to an automated powder management system” Garscha pointed out.

There are still many things to discover about OSSBERGER GmbH & Co. KG, but it is great to know that the company is already part of the short list of players that can scale and automate post-processing operations.

“We would like to bring our many years of experience in the line-integrated and automated cleaning of machined parts into the world of additive manufacturing and hope to offer smart solutions to potential customers”, the business unit director concludes.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com