A new collaboration between Optomec and Phillips Federal will enable the latter to commercialize Optomec Laser Engineered Net Shaping (LENS) systems to U.S. government facilities.

Phillips Federal is one of the providers of manufacturing equipment to the U.S. government. The company supplies access to new technologies, represent the most respected brands, and offer unparalleled engineering expertise in both traditional and additive manufacturing. In other words, a good opportunity to seize for Optomec to position itself in the public affairs of the State.

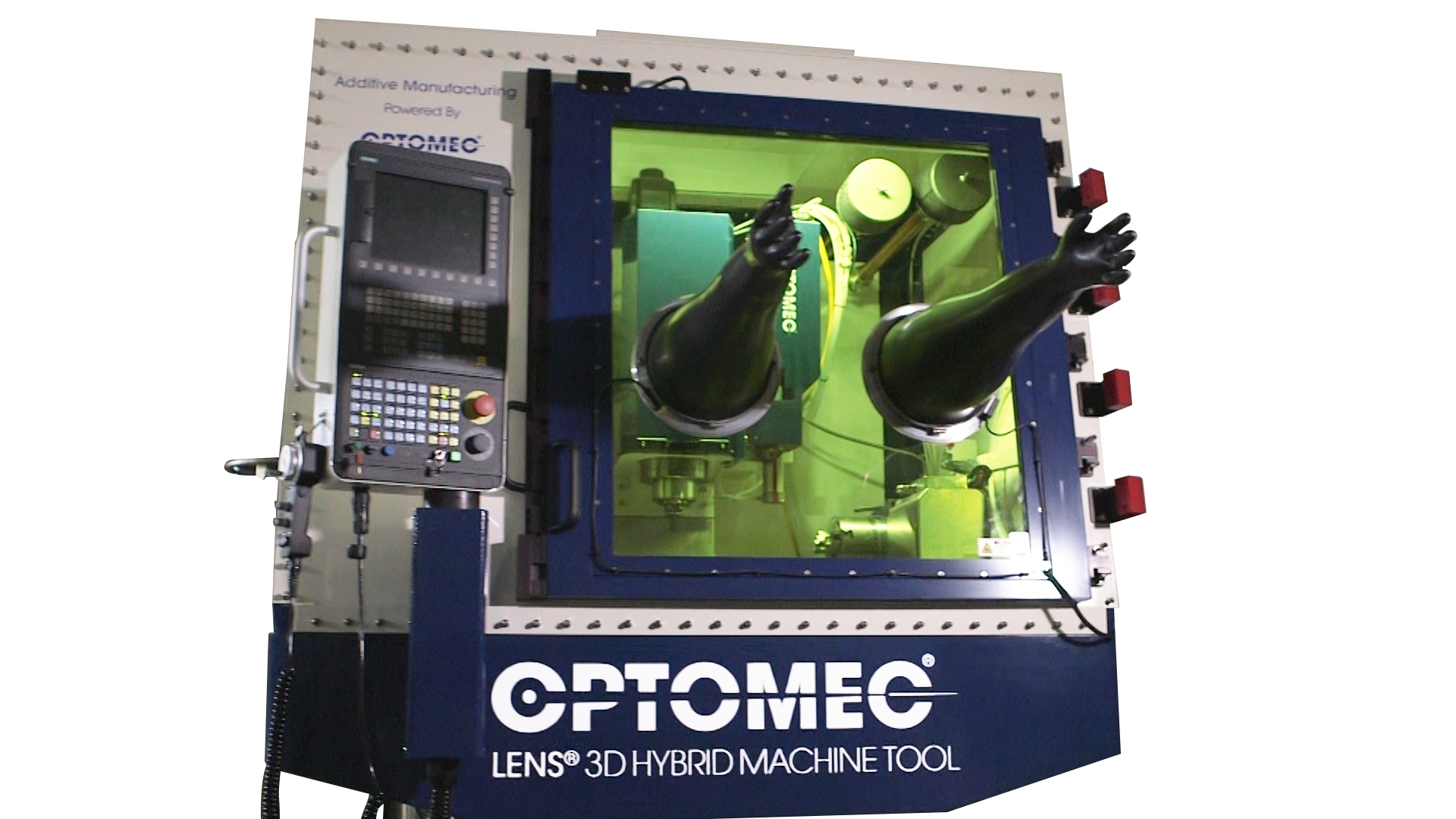

Optomec LENS systems is complementary to other types of metal AM technologies, especially Powder Bed Fusion (PBF), or Selective Laser Melting (SLM). The system integrates the Directed Energy Deposition (DED) that will enable Phillips to maintain the readiness of the military and advance the research and development of new innovations and ideas throughout our government.

LENS distinguishes itself from others of the same range thanks to its capacity to add metal to existing parts for repair and coating applications.

“Our partnership with Phillips Federal will take the LENS technology to U.S. government facilities enabling them to achieve multiple strategic objectives. Additive manufacturing technology will improve maintenance and repair operations, get equipment operational faster, and improve supply chain capability all at significantly lower cost than traditional methods,” said Mr. Jamie Hanson, VP of Business Development at Optomec. “Phillips has a very long and successful track record of working closely with customers to achieve their objectives, and together with Optomec, we expect to make a significant impact.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com