Optomec, a supplier of additive manufacturing (AM) equipment and software today has added an aluminium 3D printing capability to the company’s LENS Directed Energy Deposition (DED) systems. This innovation can be used to deposit any aluminum alloy, including those recently developed specifically for improved properties with AM processing.

This development for the Optomec DED process opens the transportation and aerospace industries to AM and repair of complex aluminum alloy parts using powder-based DED. Additionally, the use of Optomec’s LENS simultaneous 5-axis system enables the processing of aluminum alloy parts with complex geometries without the need for support structures. Deposition of aluminum alloys in a controlled atmosphere glove-box with very low levels of oxygen and moisture ensures achievement of components with superior mechanical properties.

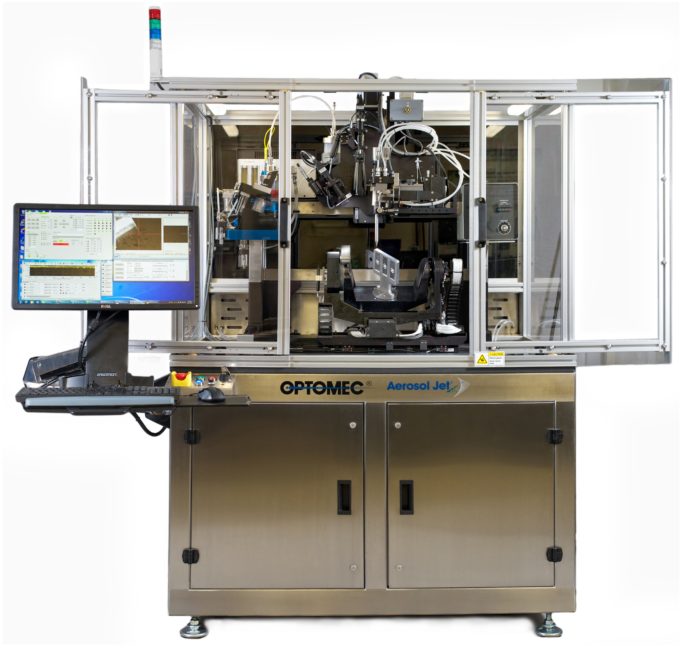

David Otazu, LENS Applications Engineer states “Our engineers have developed process parameters for aluminum alloys to provide an excellent surface finish, high deposition rates and a density of ~99.9% (photos below).” With this advancement, Optomec LENS systems can successfully process all common materials used for AM including Steels, Titanium, Nickel, Copper, and now, Aluminum.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT

Media or look for a job via our job board. Make sure to follow us on our social

networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured

in the next issue of our digital magazine or if you hear a story that needs to

be heard, make sure to send it to contact@3dadept.com