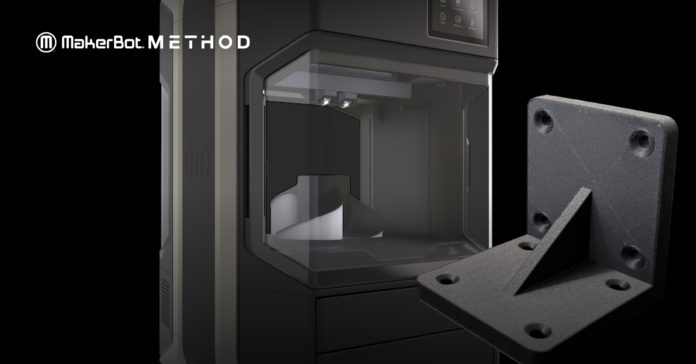

MakerBot completes its portfolio of composite materials with Nylon 12 Carbon Fiber. The new composite can be processed with the MakerBot METHOD™ and MakerBot METHOD X™ 3D printers using the MakerBot Composite Extruder as well as on the METHOD Carbon Fiber Edition 3D printers.

The material integrates a nylon 12 base polymer and absorbs less moisture than nylon 6/66, therefore, retains more of its performance in the presence of moisture. According to Stratasys’ subsidiary, engineers that will use this material will get a smooth carbon fiber 3D printing experience.

“Composite materials are ideal for a range of engineering applications. The MakerBot® Nylon 12 Carbon Fiber, in particular, offers manufacturers a cost-effective and lightweight alternative to metal 3D printing due to its high dimensional stability and excellent resistance to cracking under stress,” said Nadav Goshen, CEO, MakerBot. “By expanding the material options available for use with the METHOD 3D printers, we are providing more opportunities for users to explore new applications.”

What makes the processing of Nylon 12 Carbon Fiber unique is that MakerBot Composite Extruder is equipped with hardened metal drive gears, a metal filament switch, and an interchangeable hardened steel nozzle that facilitate the printing of high-performance materials.

Furthermore, in the METHOD Series, the dry-sealed filament bays help the materials dry, which enhances the print quality and reliability, not to mention that, users can always rely on PVA or Stratasys® SR-30™ soluble supports, as well as breakaway supports for faster print results.

Since it delivers a tensile modulus of 6000 MPa, the Nylon 12 Carbon Fiber would be suitable for applications that require parts to hold their form with minimal flex, such as automotive brackets or inspection gauges.

Lastly, in addition to engineering-grade materials from MakerBot’s materials partners, the Nylon 12 Carbon Fiber completes a portfolio that already includes PC-ABS, ABS, Nylon Carbon Fiber, PETG, ASA, and more. Shipments for the new material are expected to begin in November 2020.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com