nLIGHT, a provider of high-power semiconductor and fiber lasers, launches the Corona AFX-2000, a two-kilowatt laser that could boost productivity in laser powder bed fusion processes.

The AFX-2000 laser integrates the company’s proprietary beam-shaping technology and has already undergone successful commercial validation with a customer supporting the aerospace, defense, and automotive end markets. Using aluminum alloys, this customer is now achieving print speeds up to three times faster when compared to today’s leading large-format printers, nLIGHT said.

Read more: The importance of lasers in AM machines

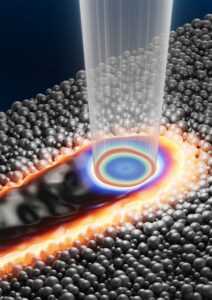

With advanced dynamic laser beam shaping, the AFX-2000 delivers twice the power of today’s top lasers, all while keeping the process stable. This increase in power leads to greater productivity and lowers the cost per part, without compromising the consistency needed for producing high-quality parts.

“The exclusive beam profiles of the AFX-2000 have brought L-PBF print speeds to exciting new levels while maintaining precision, control and material quality for laser powder bed fusion,” said Rob Martinsen, Chief Technology Officer of nLIGHT. “The dynamic beam shaping technology in these lasers allows for productivity-optimized switching between profiles ideal for fine-scale features and contour exposures, to extremely fast and highly reproduceable build rates using ring beam profiles, making it the most versatile and efficient laser available for metal AM. We anticipate the AFX-2000 to be widely adopted for highly reflective alloys such as aluminum and copper, materials that benefit greatly from stable, high-brightness laser processing. The AFX-2000 will enable our customers to meaningfully reduce part costs for high-volume manufacturing.”

Now in production, the AFX-2000 is offered in nLIGHT’s modulus™ platform, an integrated multi-laser sub-system designed for ultra-high-productivity laser powder bed fusion printers. The feature-rich modulus platform greatly simplifies the integration, control, and serviceability of multi-laser printers, while enabling new levels of machine utilization and reproducibility of production parts.

Visitors at Formnext could discover more about nLIGHT’s new laser.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.