It looks like this year is the turn of Nexa3D to shake the Mergers & Acquisitions field up. On the heels of the acquisition of XYZ Printing’s SLS 3D Printing Business, the developer of polymer 3D printing technologies acquires Addifab, the company behind Freeform Injection Moulding – a hybrid technology that we qualified as both additive manufacturing and injection moulding. AddiFab’s proprietary end-to-end digital tooling solution includes CAD-to-Tool software generator, dissolvable tooling resins, 3D printing and production injection molding process.

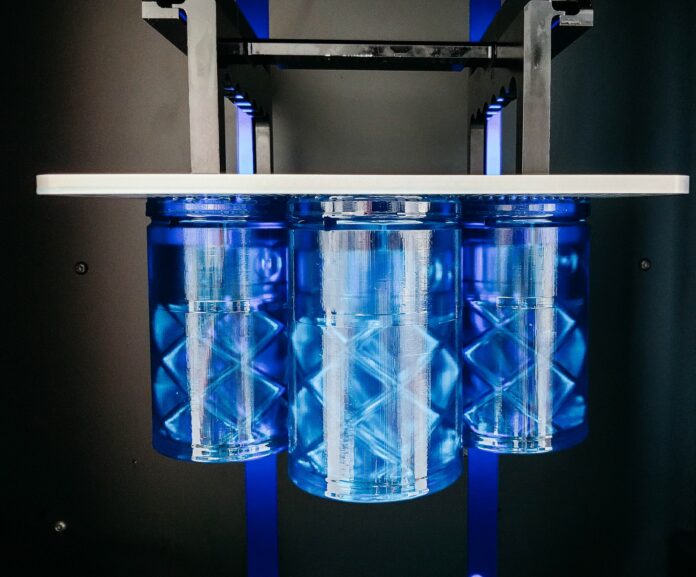

Interesting, Nexa3D knows exactly where it is getting into as both companies have been working together since the past year. Together, they have developed a manufacturing solution that combines the best of Nexa3D’s ultrafast 3D printers with Addifab’s high-temperature soluble resins; a solution that can print complex tools that are compatible with any injection molding feedstock.

Most notably, the combined solution was used by Wilson Sporting Goods to accelerate the development of youth baseball bats. Wilson’s R&D team was able to produce and test multiple designs simultaneously using final manufacturing materials, something they could not have accomplished before with any other 3D printed tool, Nexa3D recalls.

“We are very excited to welcome the entire Addifab team to the growing Nexa3D family of people, products and partners democratizing access to dissolvable tooling for same day complex molded parts using the entire range of industrially proven plastics,” said Avi Reichental, Co-founder, Chairman and CEO of Nexa3D.

In AddiFab’s solution, the xMOLD resin is compatible with the entire range of off-the-shelf thermoplastic materials, including reinforced high-performance feedstocks. Additionally, metals, ceramics, and silicones are also covered, enabling users of Nexa3D printers to tap into applications that would normally require a substantially larger capital investment. A tool printed with the xMOLD resin is soluble, meaning it does not require complex slides and gates, giving customers the ultimate flexibility to test and iterate more frequently. Finally, you don’t have to be a toolmaker to quickly design an injection molding tool using the Addifab tool maker software or Solidworks, a press release explains.

As part of its growing commitment to EMEA, and in service of its growing reseller partner network, Nexa3D plans to immediately leverage Addifab’s Copenhagen facility as its Customer Experience Center, inclusive of a product showroom, service and support hub for its European-based customers, and a main warehouse and logistics center in Europe, one learns.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com