Rapid+TCT is one of those events that is acknowledged as the place-to-be when you are part of the additive manufacturing industry. Just as at every event, companies make new revelations regarding their sector of activity. This year, we are still seduced by some of them:

Stratasys, its 3D printers compatible with carbon fiber composite material and solutions for color and speed.

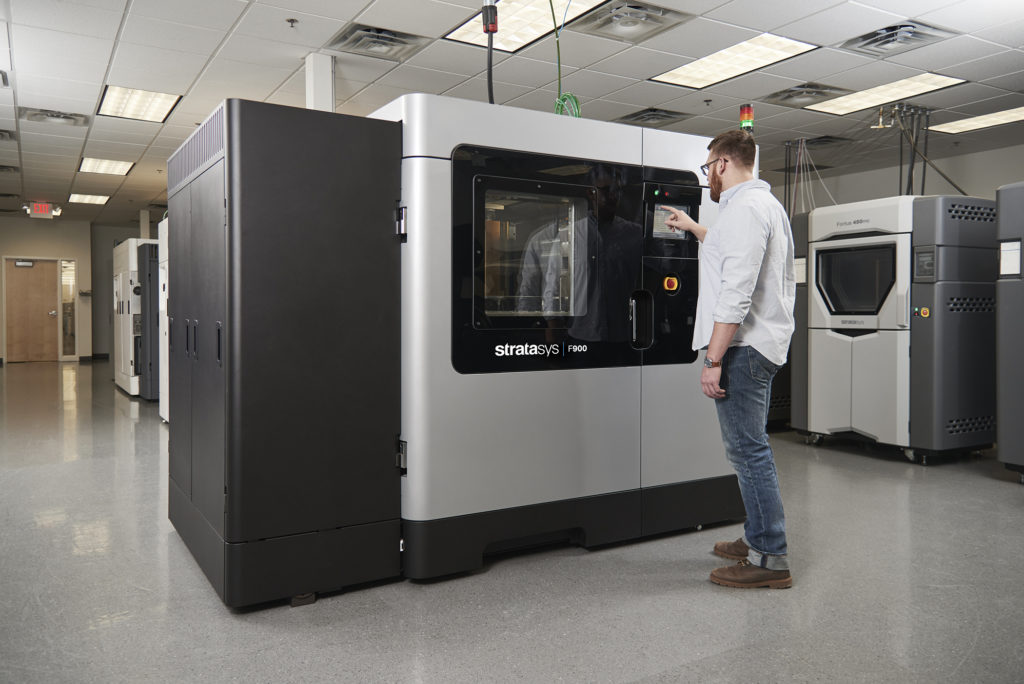

The new F900 Production 3D Printer is the third generation of the company’s flagship FDM system. Main characteristics include an MTConnect-ready interface with production-ready accuracy and repeatability.

The manufacturer’s Fortus 3D printers help for rapid tooling, jigs, fixtures and part production applications. In this case, the two Fortus are intended for the aeronautics sector.

With the Stratasys F900 Aircraft Interiors Certification Solution (AICS), customers are sure that performance and traceability required for flight-worthy parts will all be part of the production process.

As for the Stratasys F900 PRO, the production-grade system enables to produce parts with the highest FDM repeatability and performance in ULTEM 9085 resin. “It includes all the benefits and value of the AICS product, and it extends the high repeatability developed for AICS to all industries.”

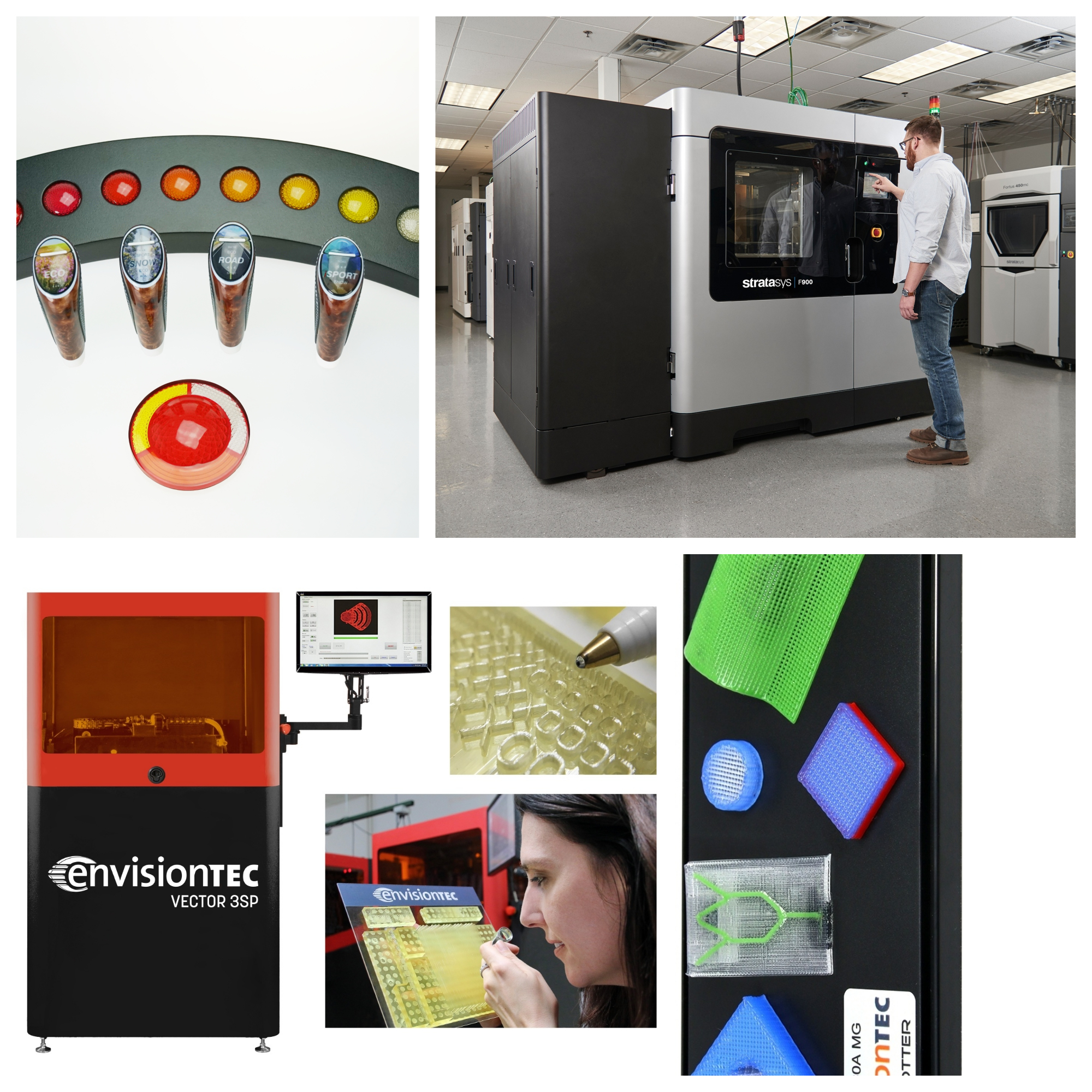

Its solutions for color and speed

Following the demand of auto manufacturers, the company improved its J750 3D Printer and offers 500,000 color combinations via a new vivid color package, highly accurate color matching, and advanced clear with texture functionality.

Also, GrabCAD Print software has been improved. Available for the Connex3 3D Printer, it improves workflows and functional prototyping for parts requiring ABS-level plastic simulation and tear-resistant rubber-like parts.

“With the new vivid colors solution on the J750 3D Printer, we are able to produce prototypes with incredible realism, such as the transparent multi-color covers for our tail lights. This can offer the texture and color-matching requirements to meet our design approval process.” Therefore, it could reduce time and cost required for each design process, explain Reinhard Schiechel & Dr. Tim Spiering, Audi Model shop and 3D printing center.

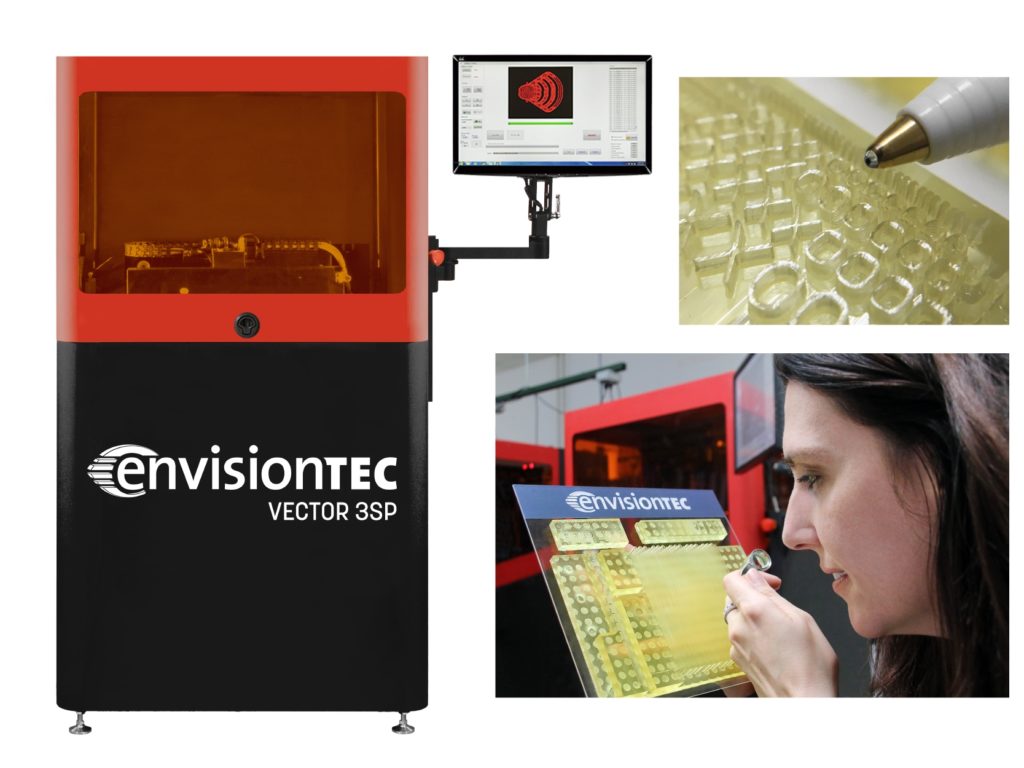

EnvisionTEC and its large frame 3D printer

EnvisionTEC unveils new 3D printers integrating the 3SP Technology (Scan, Spin and Selectively Photocure). The latter is used as a laser-based process to cure photopolymers in a large vat.

The new 3D printers are the Vector UHD 3SP, with a build area of 300 x 200 x 275 mm (11.8 x 7.9 x 10.8 in.) and the Xede UHD 3SP, with a build area of 457 x 457 x 457 mm (18 x 18 x 18 in.). Furthermore, with the hardware upgrade, the company will deliver XY resolution of 25 microns, “a precision level equivalent to about half the cross-section of a human hair.”

As far as materials are concerned, two new medical-grade materials will enable to produce 3D printing parts for implantation in humans safe and easy on its bioprinters.

UV Silicone 60A MG is a biocompatible, bio-inert, non-biodegradable liquid silicone rubber that is cured with a UV light and delivers a Shore A hardness of 60. A transparent material, it can also be mixed with pigments. Approved only for short-term use in the body (29 days or less). Sold by the kilogram. Suitable applications include microfluidics, wound dressings, bio-sensor housings and prototyping.

HT PCL MG is a biodegradable thermoplastic polyester that is processed at high temperatures. To be offered in two molecular weights that affect stiffness, flexibility and degradation time: 80 kDa and 120 kDa. Available in 1 kg or 100 g packages. Suitable for both short-term and long-term use in the body (longer than 29 days). Ideal applications include bone regeneration, cartilage regeneration, drug release and hybrid scaffolds.

The medical industry will be happy for those announcements!

![]()

Optomec: 3D printed electronics and 3D printed metals

Optomec will showcase its Aerosol Jet Systems for Printed Electronics and LENS systems for 3D printed metals. Live demonstrations of the five axis Aerosol Jet 5x system for printed electronics could be interesting to discover for those who attend the show.

GlowForge launched its 3D Laser Printer

Useful products can be created from leather, wood, fabric, paper, and many more. Discover in video the 3D printer:

MakerGear and its new products

The company has unveiled M3 Independent Dual Rev. 1 3D Printer with enclosure, an improved version of its M3 printer and a Cloud software designed to optimize the productivity of a 3D printer “fleet through printer cluster mapping and cluster-based print queuing, while protecting users’ IP through advanced administrative control.”

True Leveling & Auto Leveling: “All new M3-ID Rev 1 printers will feature a touch probe that expedites, manages and improves the print bed leveling process by providing simple instructions to the user if needed. In addition, the probe also checks the print surface to generate a mesh using 9 data points to compensate for any unavoidable variations in the flatness of the print bed.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});