This edition of news roundup covers the latest news on new facilities, certifications, online courses and acquisitions.

New R&D facility in the Basque Country to drive advanced manufacturing

OEM Renishaw, and the research center IDEKO, have inaugurated a new Renishaw Solutions Centre in Elgoibar (Gipuzkoa), Spain. The new Research & Development (R&D) facility aims to develop innovative solutions in advanced manufacturing.

This laboratory, located on the premises of the Basque Research and Technology Alliance (BRTA) member center, forms part of the collaboration agreement signed between the two organizations at the 2024 International Machine Tool Exhibition in Bilbao, Spain.

This long-term partnership agreement also involves Danobatgroup, an expert in the field of machine tools. The Solutions Center drives innovation for this group, while Renishaw has been a long-term technology supplier across several of its product lines.

Materialise has gained EN 9100 certification for its metal AM processes for aerospace

Belgian AM giant Materialise has obtained EN 9100 certification for its aerospace metal AM processes. EN 9100 is a sector-specific variant of ISO 9001; it certifies that an organization has implemented a quality management system that ensures product quality, process control, regulatory compliance, and continuous improvement.

Materialise already holds EN 9100 for its polymer additive manufacturing processes dedicated to the sector, producing upwards of 500,000 flying parts to date for aircraft OEMs, suppliers, and MROs. The development, therefore, represents a step forward in the adoption of metal 3D-printed parts for aviation and space.

With EN 9100 certification for metal now complementing its existing credentials, Materialise is ready to help the entire aerospace value chain identify and source flight-ready metal or polymer 3D-printed parts — with low-criticality parts a particularly strong opportunity for the sector.

Replique receives ISO 27001 certification for information security

Replique, a provider of an industrial procurement platform for demanding requirements, has received ISO/IEC 27001:2022 certification. This internationally recognized standard confirms that Replique maintains the highest standards in data protection within its Information Security Management System (ISMS) and continuously monitors its processes for potential security risks.

Given Replique’s daily handling of sensitive company data, robust data security is essential. Since its founding, the protection of sensitive technical customer data through end-to-end encryption along the entire production chain has been a key feature of the decentralized procurement platform.

In 2024, Replique obtained ISO 9001 certification for its quality management system. The recent ISO 27001 certification, audited by TÜV Süd, marks another significant milestone and positions Replique well for the upcoming NIS2 directive requirements – a clear sign of the company’s commitment to maintaining the highest standards in both data security and quality.

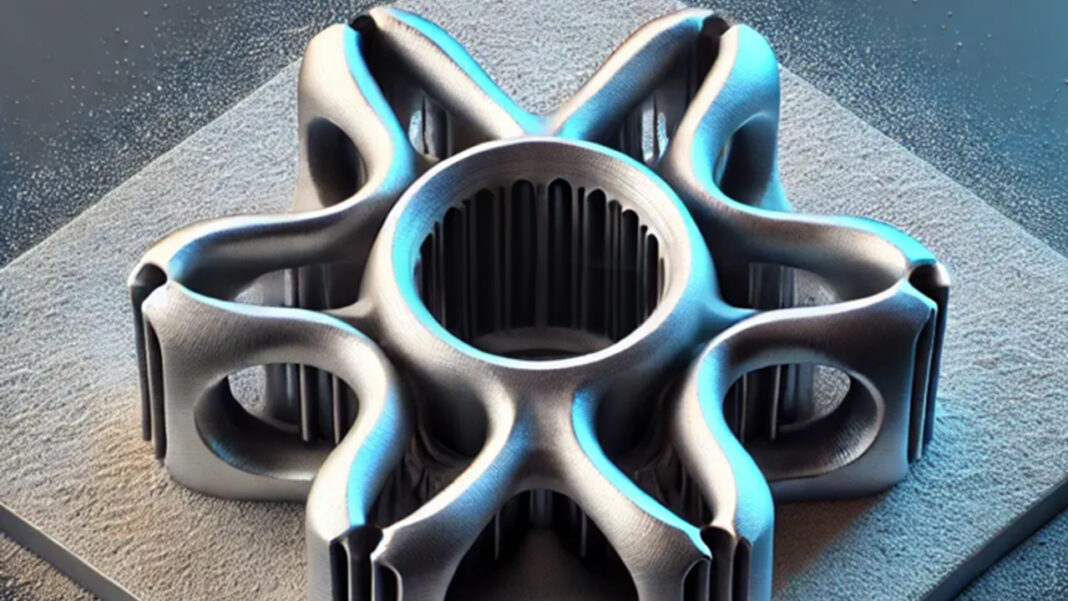

Siemens and U-M announce a free online course on metal AM

On the heels of its “Siemens for Startups” program, Siemens Digital Industries Software joins forces with the University of Michigan, to launch a Massive Open Online Course (MOOC).

Named ‘Introduction to 3D Printing with Metals,’ the MOOC provides an open, accessible resource to professionals, hobbyists and students alike.

Siemens worked with Chinedum Okwudire, professor of mechanical engineering at U-M, and Dr. Nathaniel Wood to design the course. It provides essential information about methods of printing using metals, how they work, their advantages and limitations, and most importantly, their practical applications.

Available on Coursera, the ‘Introduction to 3D Printing with Metals’ course covers basic, desktop forms of 3D printing with metals to more complex processes, such as powder bed fusion, jetting-based and direct energy deposition processes – from pre-processing and design for additive manufacturing to post-processing and part-finishing. Participants learn about 3D printing and additive manufacturing with metals through examples and interviews with industry experts and gain hands-on experience with 3D printing within a smartphone or desktop-accessible augmented reality experience.

Tethon 3D acquires a subsidiary of SINTX Technologies, Inc.

From a ceramics company to another one.

Ceramic 3D printing material company Tethon 3D has acquired Technology Assessment and Transfer (TA&T), a subsidiary of Sintx Technologies. SINTX is an OEM of advanced ceramics who acquired TA&T in 2022.

TA&T is a nearly 40-year-old advanced ceramics business that specializes in developing and commercializing a broad array of innovative materials for defense, biomedical, and industrial applications. The company’s technologies and products include 3D printing of ceramic medical devices and heat exchangers, chemical vapor infiltration and deposition of complex fiber-reinforced ceramic-matrix composites, and hot pressing of transparent armor and other technical ceramics.

For Tethon 3D, founded in 2014, this acquisition is an opportunity to expand its manufacturing capabilities and resin portfolio while increasing its global market share. Moving forward, Tethon will have two headquarters, with facilities in Omaha and the D.C. Baltimore Metro Area to ensure “continuity and a seamless transition.”

Featured image: Image courtesy of University of Michigan

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com